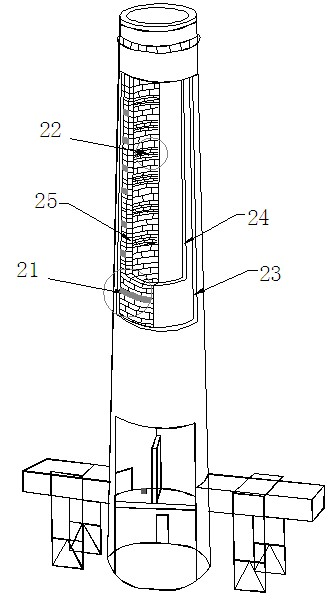

Corrosion-resistant treatment method of corbel part of brick lining chimney

A technology of anti-corrosion treatment and inner lining, which is applied in the field of anti-corrosion treatment of brick-lined chimneys, and can solve problems such as anti-corrosion failure, chimney anti-corrosion failure, and anti-corrosion layer that cannot relieve stress, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

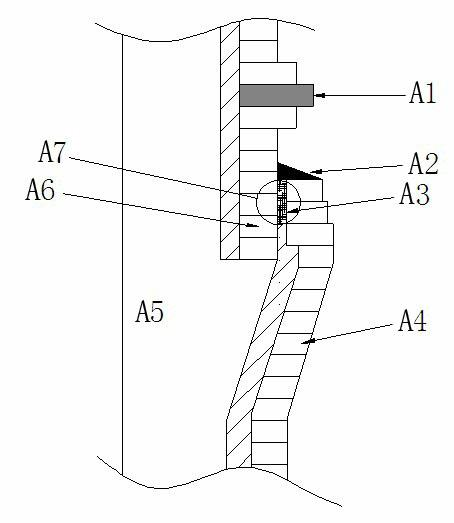

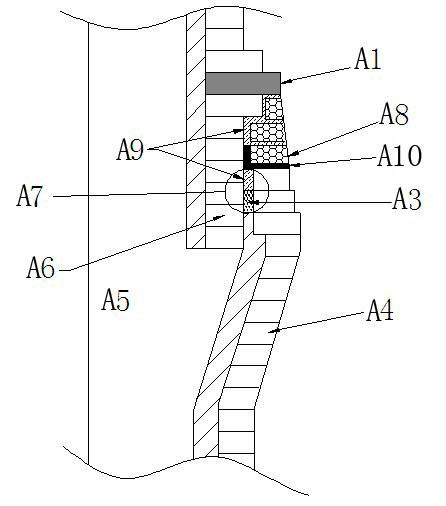

[0037] The anticorrosion treatment of embodiment 1, class A corbel, as image 3 Shown:

[0038] (1) Rinse the corbels with water, and manually remove the mortar and acid-resistant mortar in the A7 area of the corbel joint, and remove the impurities in the corbel joint A7;

[0039] ⑵Put the prepared thermal insulation sliver A3 into the transfer joint A7, and reserve a depth of about 100mm in the transfer joint A7;

[0040] (3) Pour polyurethane sealing paste into the joint A7, and the pouring depth of polyurethane sealing paste is 50mm;

[0041] (4) On the surface of the polyurethane sealing paste, pour silicone rubber high-temperature elastic bonding sealing material A9 to a depth of about 50mm;

[0042] (5) On the brick matrix inside the joint A7, use the mixture A10 of VP3-2 and silicone rubber high-temperature elastic bonding and sealing materials to build the first piece of vitrified ceramic brick A8;

[0043] ⑹Finally, use silicone rubber high-temperature elastic ...

Embodiment 2

[0045] The anticorrosion treatment of embodiment 2, B class beef leg, as Figure 5 Shown:

[0046] ⑴Rinse the corbels with water, and manually remove the mortar and acid-resistant mortar in the B1 area of the joint; remove impurities in the joint;

[0047] ⑵Put the prepared thermal insulation sliver B2 into the joint B1, and reserve a depth of about 100mm in the joint B1;

[0048] (3) Pour polyurethane sealing paste into the joint B1, and the pouring depth of polyurethane sealing paste is 50mm;

[0049] (4) On the surface of the polyurethane sealing paste, pour silicone rubber high-temperature elastic bonding sealing material to a depth of about 50mm;

[0050] (5) In the joint B1, the first vitrified ceramic brick B6 is built with the mixture B7 of VP3-2 and silicone rubber high-temperature elastic bonding and sealing material;

[0051] ⑹Finally, the remaining vitrified ceramic bricks are filled with silicone rubber-based high-temperature elastic bonding and sealing mat...

Embodiment 3

[0055] Embodiment 3, the anticorrosion treatment of class C corbel (ring beam), such as Figure 7 Shown:

[0056] (1) Rinse the corbel with water, and manually remove the three bricks along the lower edge of the ring beam to remove impurities in the joint C4;

[0057] (2) Insert the prepared thermal insulation sliver into the joint C4, and reserve a depth of about 100mm in the joint C4;

[0058] (3) Pour polyurethane sealing paste C7 into the seam, and the pouring depth of polyurethane sealing paste is 50mm;

[0059] (4) On the surface of polyurethane sealing paste C7, pour silicone rubber high-temperature elastic bonding sealing material to a depth of about 50mm;

[0060] (5) On the top of the joint C4 filled with sealing material and the inner liner at the edge of the joint, use the mixture C6 of VP3-2 and silicone rubber high-temperature elastic bonding sealing material to build the first vitrified ceramic brick C8;

[0061] ⑹ Finally, use silicone rubber high-tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com