Ultrasonic liquid-level monitoring system for oil-field fracturing additive in tank

A technology for liquid level monitoring and oil field fracturing, applied in signal transmission systems, liquid/fluid solids measurement, measurement devices, etc. The effect of labor intensity, strict management and waste reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

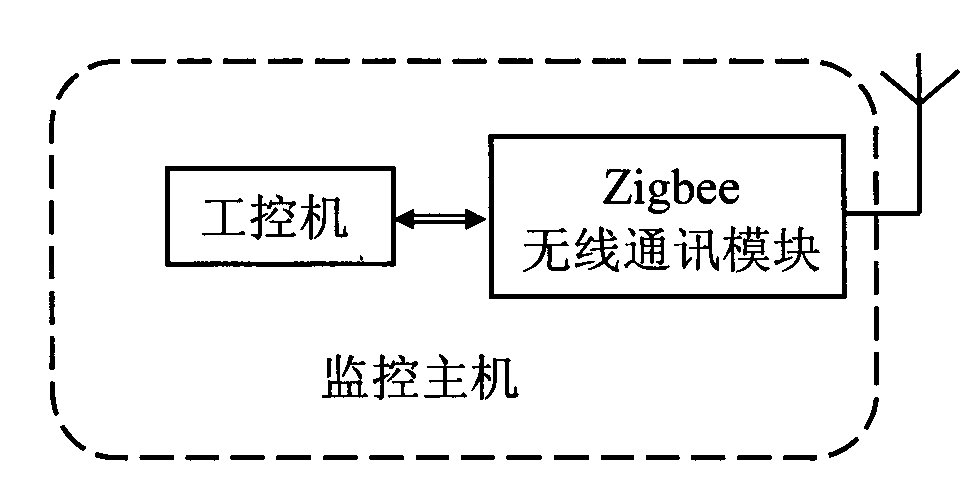

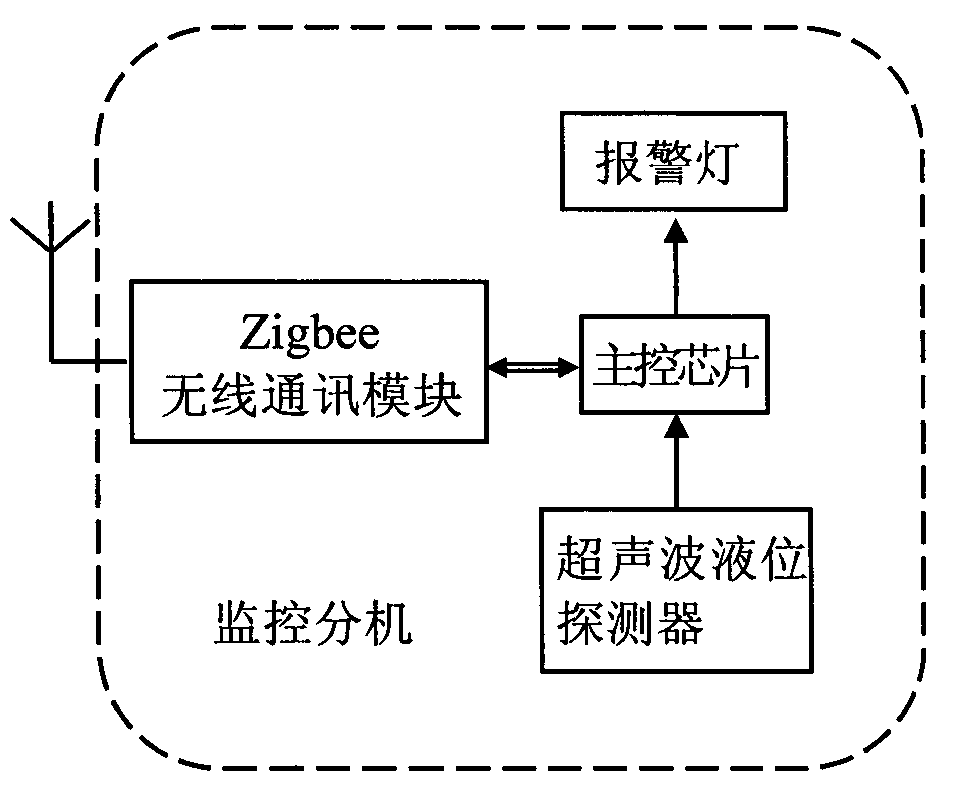

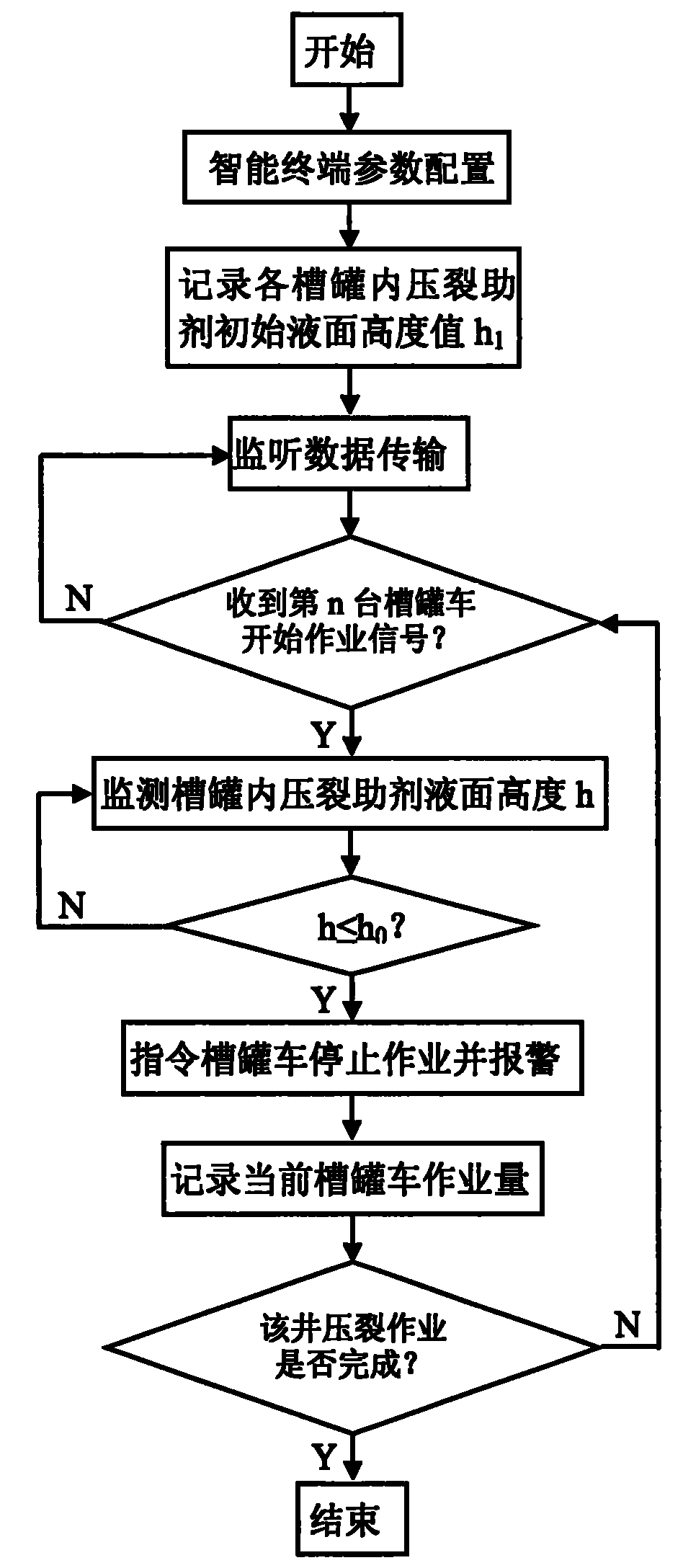

[0008] The present invention is a Zigbee wireless communication network. A monitoring host is located on the main node of the Zigbee wireless communication network, and the main node is located on the command vehicle. The monitoring host is composed of industrial computer and Zigbee wireless communication module, see figure 1 As shown, the industrial computer adopts a microcomputer, and the microcomputer and the Zigbee wireless communication module are connected through a serial port such as RS232 to realize mutual data transmission between the two; a level conversion circuit is added between the microcomputer and the Zigbee wireless communication module to solve the problem of power failure. Matching problem. Several monitoring extensions are located on several slave nodes of the Zigbee wireless communication network, and each slave node is located on a tank car. The ultrasonic liquid level detector is an integral part of the monitoring extension, installed on the top of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com