Coaxial dual-electron beam electron gun

A technology of dual electron beams and electron guns, applied in the field of electron guns, can solve problems such as difficult to improve performance, cannot be set arbitrarily, and difficult to miniaturize devices, so as to achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

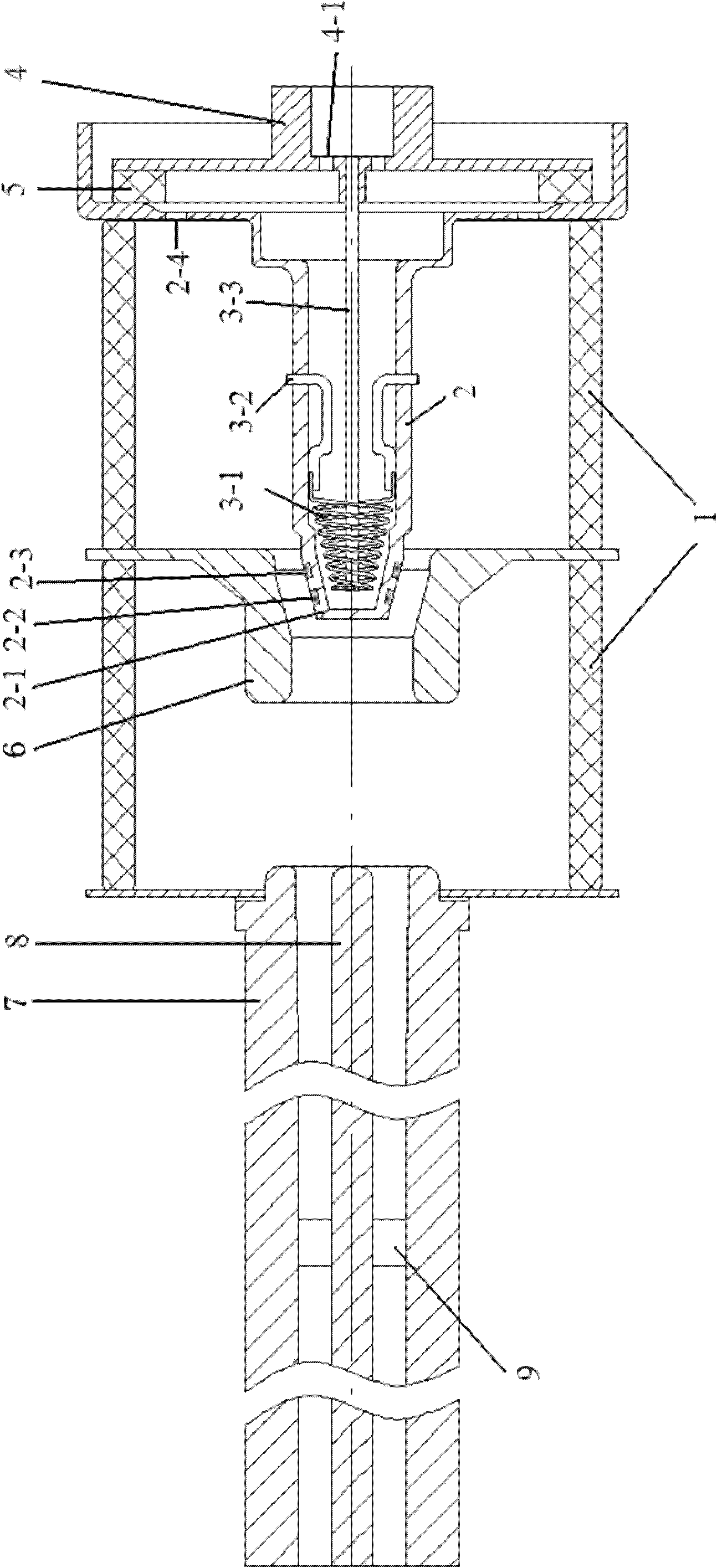

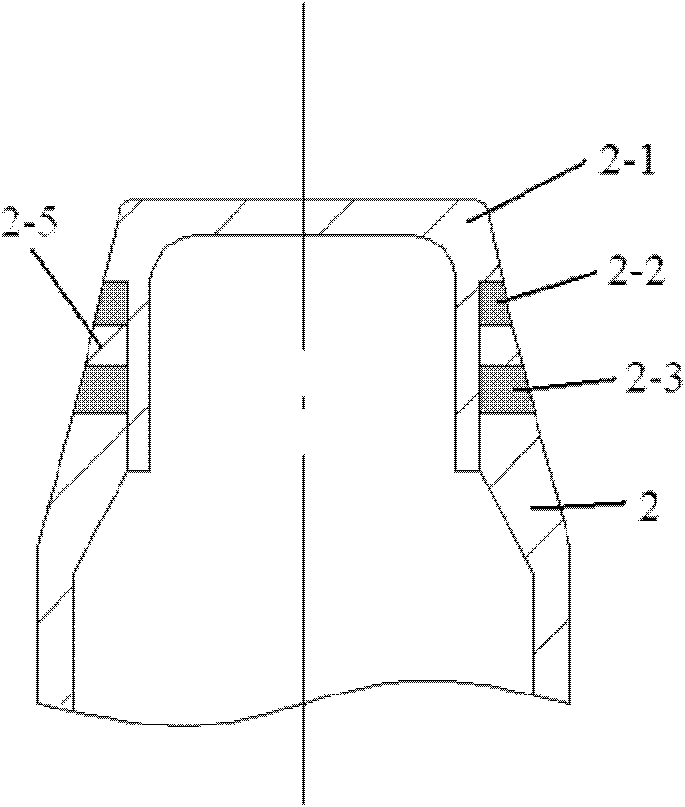

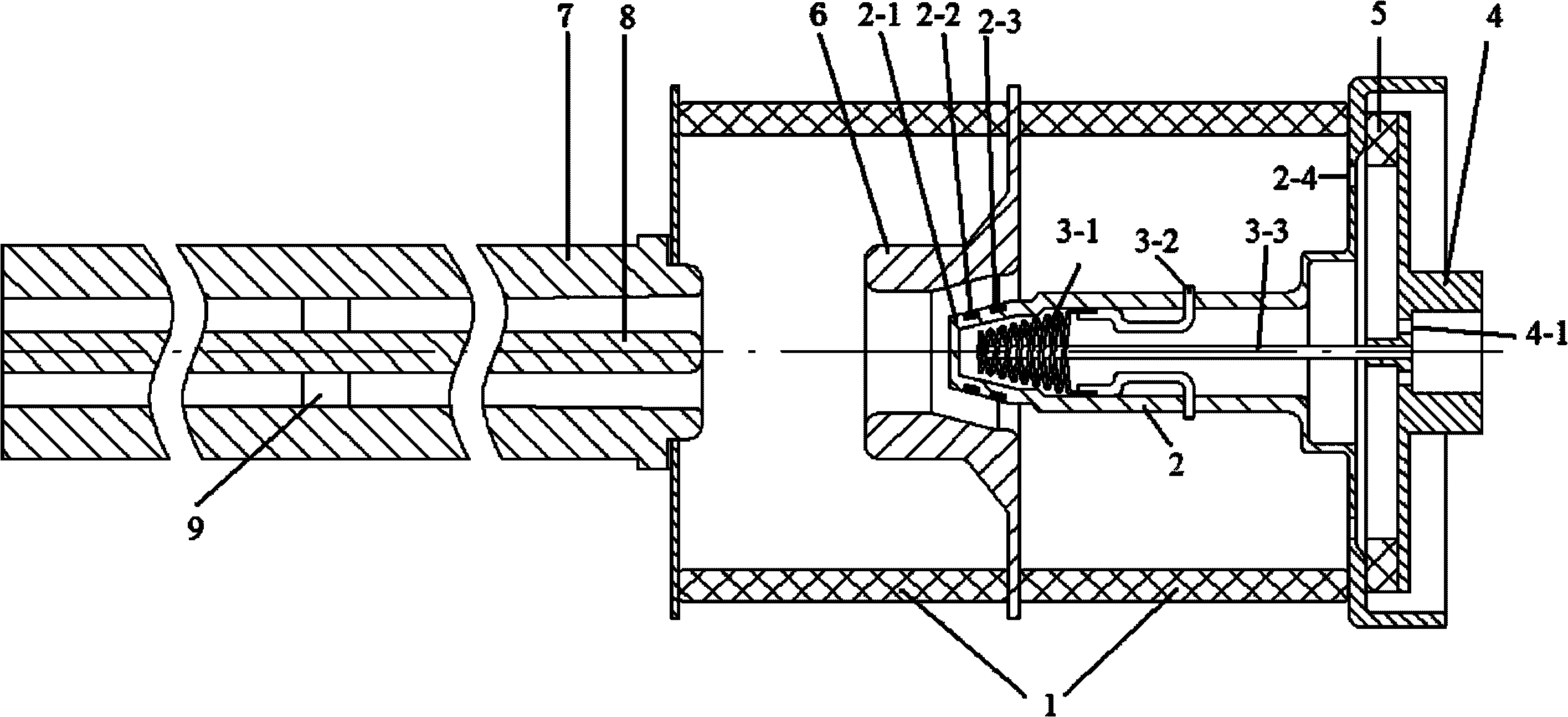

[0012] Take the coaxial double electron beam electron gun used in conjunction with the coaxial resonant cavity double electron beam gyrotron used for heating plasma as an example: the electron gun barrel 1 has an axial length of 250mm, and the inner and outer diameters are Φ120mm and Φ150mm respectively. for 99 # Ceramics, two ports are metallized, the upper and lower sections of the cylinder body 1 in this embodiment are sealed into a whole with the chassis of the control anode 6; the axial length of the cathode sleeve 2 is 200mm, and the outer diameter of the main (sleeve) body part of the cathode sleeve is Φ54mm, wall thickness 5mm, front conical cathode head 2-1 length 25mm, inclination angle 15 degrees, cathode sleeve 2 is sealed with the rear end surface of electron gun barrel 1 and insulating ring 5 respectively through its fixing seat with vent hole 2-4 Fixed; the diameters of the upper and lower ring openings of the electron beam emitting ring 2-2 are Φ47.8mm and Φ48....

Embodiment 2

[0015] In this embodiment, the cathode head 2-1 adopts a combined cathode head as an example: the electron beam emission rings 2-2 and 2-3 all adopt ring cone emission rings, and the diameters of the upper and lower ring openings of the electron beam emission ring 2-2 They are Φ47.8mm and Φ48.2mm respectively, the diameters of the upper and lower ring openings of the electron beam emitting ring 2-3 are Φ51.9mm and Φ52.1mm respectively, the inner diameters are both Φ40mm, and the inclination angle of the outer cone annulus is 15 degrees; the isolation ring 2- 5 is placed between the ring cone launch rings 2-2 and 2-3, the inclination angle of the outer cone ring surface is still 15 degrees, and the inner diameter is Φ40mm. In this embodiment, the outer diameter of the joint between the end of the cathode head 2-1 and the ring cone emission rings 2-2, 2-3, the isolation ring 2-5, and the main body of the cathode sleeve is Φ40mm, and it is welded with the main body of the cathode ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com