Stripping transfer method of substrate of thin film solar cell

A solar cell, stripping transfer technology, applied in the direction of circuits, electrical components, sustainable manufacturing/processing, etc., can solve the problems of limited use range, heavy weight of thin-film batteries, and unsatisfactory, and achieve a wide range of applications, light specific gravity, and high The effect of flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

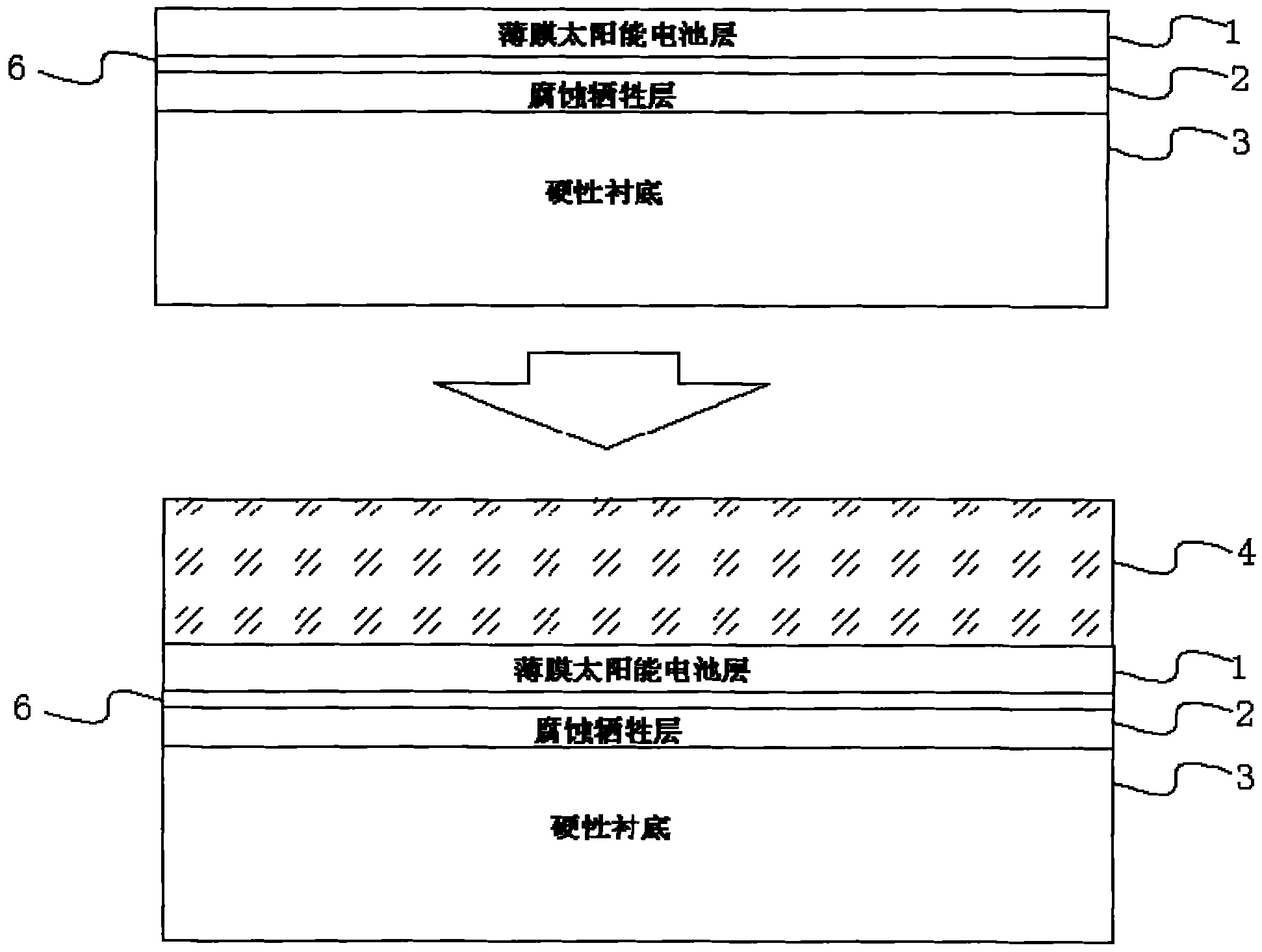

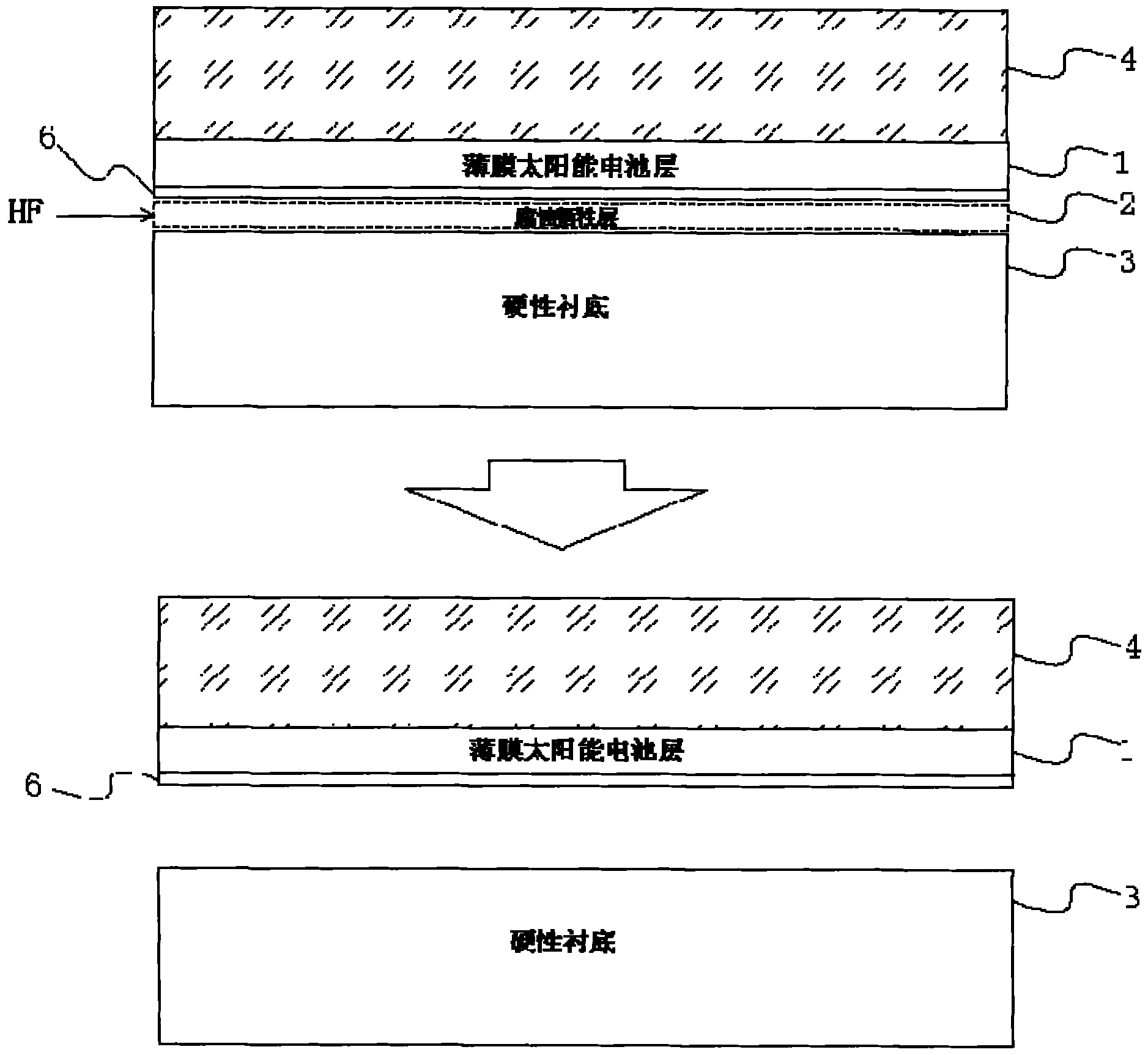

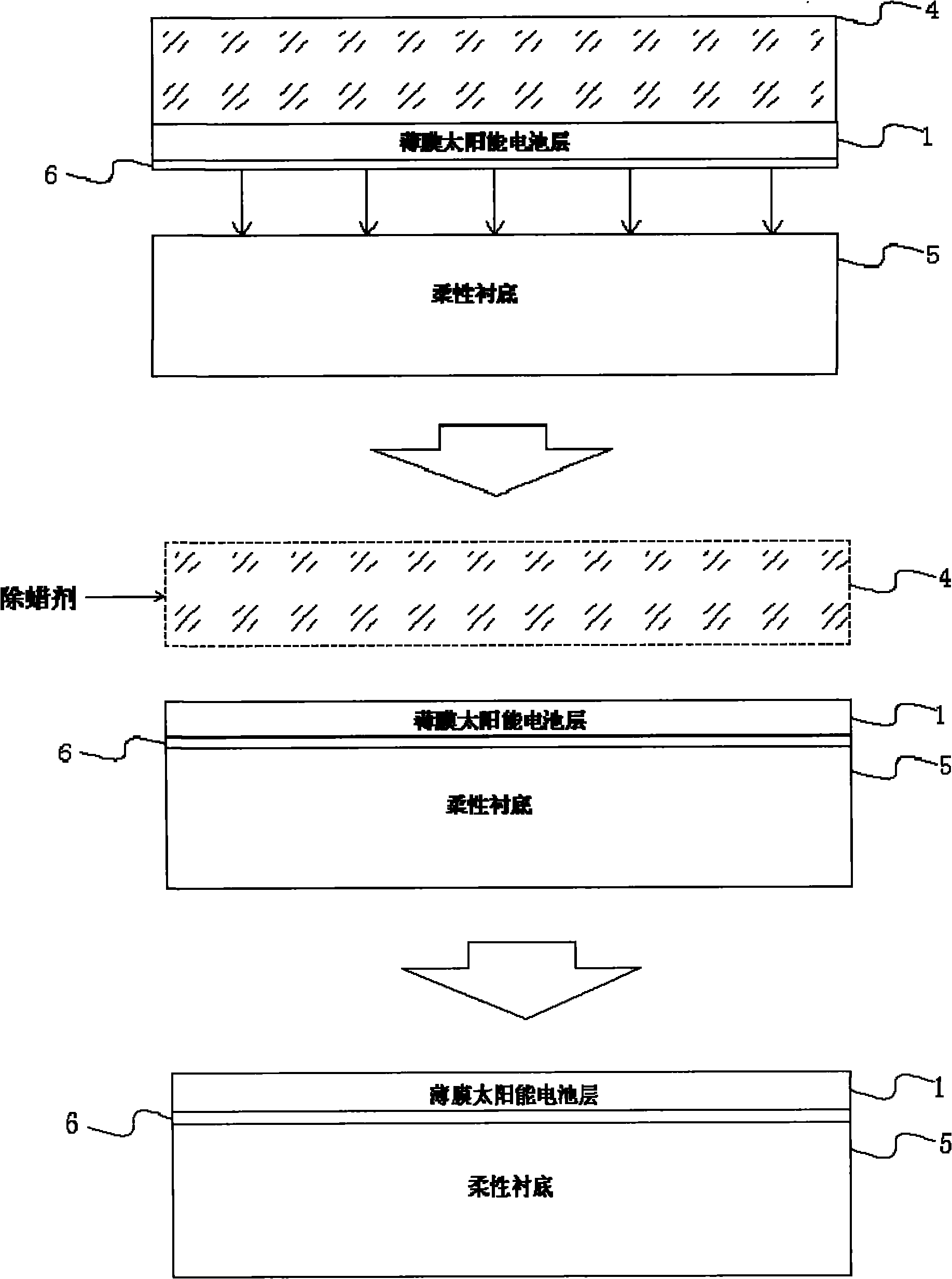

[0023] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0024] like Figure 1 to Figure 3 Shown, a kind of stripping transfer method of thin-film solar cell substrate, its concrete steps are as follows:

[0025] 1. Select a hard substrate 1. The commonly used hard substrate 1 is a GaAs substrate with a thickness between 300-500 μm. Its smoothness and hardness can ensure the high flatness and precision of the material layer deposited and grown on it.

[0026] The material aluminum arsenide (AlAs) is deposited and grown on the hard substrate 1 by molecular beam epitaxy (MBE) or metal organic chemical vapor deposition (MOCVD) to form a corrosion sacrificial layer 2 with a thickness of 0.5 μm. The corrosion sacrificial layer 2 is not a structure contained in the finished battery, but a material layer inserted for the realization of the subsequent lift-off transfer technology.

[0027] 2. Fabricat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com