Organic resistive random access memory (RRAM) with peak shaped bottom electrode and manufacture method thereof

A resistive memory, bottom electrode technology, applied in the field of microelectronics, can solve problems such as unfavorable device repeatability and stability, and achieve the effect of enhancing repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is further described below through specific process steps, wherein the top electrode and the bottom electrode are selected from metal Al material as an example, and the organic medium layer is selected from PEDOT:PSS as an example:

[0032] 1. Use conventional integrated circuit technology to obtain a standard P-type device-level substrate Si (100) sheet without graphics, with a resistivity of 6-10 Ω cm. After standard RCA cleaning process, use a 2% HF dilution solution to remove silicon Intrinsic oxide layer on the chip surface.

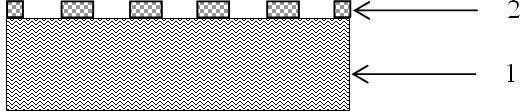

[0033] 2. Spin-coat the positive resist on a large area and perform photolithography. After developing, a dot-shaped pattern is formed, and the diameter of the dot is 50nm. Use the RIE method to use oxygen plasma to treat the sample as a base film to remove the positive glue in the non-masked area. The oxygen flow rate is 20sccm, the power is 75W, the time is 45s, and the air pressure is 4Pa, such as figure 1 shown.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com