Method for producing feed by utilizing high-concentration waste syrup of citric acid

A citric acid, high-concentration technology, applied in animal feed, animal feed, application, etc., to achieve the effects of reduced production and operation costs, high degree of automation, and improved cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

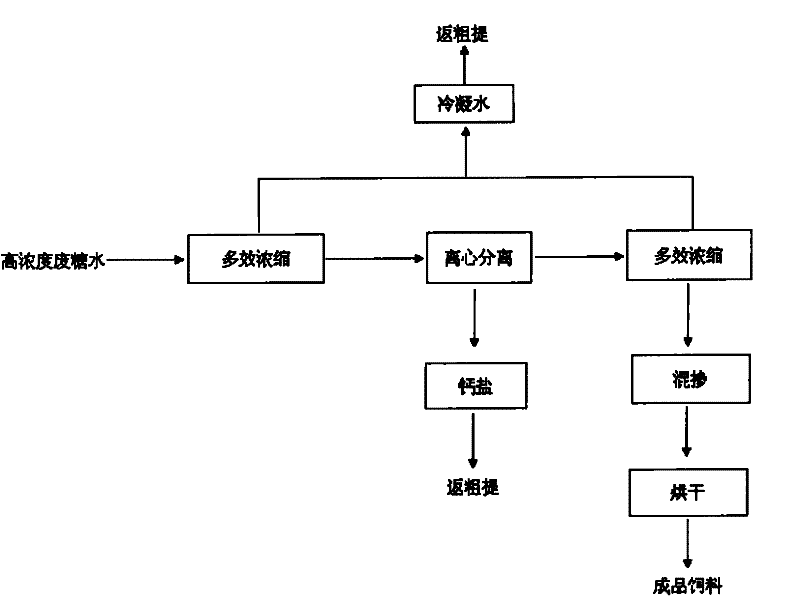

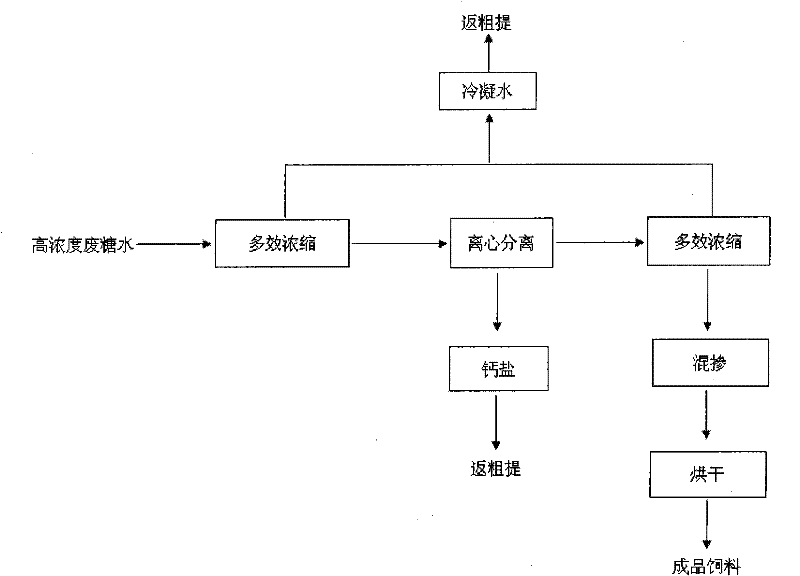

Method used

Image

Examples

Embodiment 1

[0018] 1. The high-concentration citric acid waste sugar water is concentrated once by a five-effect concentration evaporator, and the concentration of the concentrated solution is 7.5% on a dry basis;

[0019] 2. The primary concentrated liquid is separated from the solid and liquid by the centrifuge under the plate discharge;

[0020] 3. The filtrate is concentrated twice through a four-effect concentrated evaporator, and the concentration of the concentrated solution is 52.4% on a dry basis;

[0021] 4. The secondary concentrate is continuously mixed into the baked citric acid residue or sugar residue;

[0022] 5. The finished feed is obtained by mixing the ingredients for secondary drying. The protein content is 22.5%, and the moisture content is 12.0%, which meets the enterprise standard.

Embodiment 2

[0024] 1. High-concentration citric acid waste sugar water is concentrated once by a six-effect concentration evaporator, and the concentration of the concentrated solution is 8.6% on a dry basis;

[0025] 2. The primary concentrate is separated from solid and liquid by a decanter centrifuge;

[0026] 3. The filtrate is concentrated twice through a four-effect concentrated evaporator, and the concentration of the concentrated solution is 57.5% on a dry basis;

[0027] 4. The secondary concentrate is continuously mixed into the baked citric acid residue or sugar residue;

[0028] 5. The finished feed is obtained by mixing the ingredients for secondary drying, with a protein content of 20.0% and a moisture content of 14.0%, which meet the enterprise standards.

Embodiment 3

[0030] 1. The high-concentration citric acid waste sugar water is concentrated once by a five-effect concentration evaporator, and the concentration of the concentrated solution is 6.5% on a dry basis;

[0031] 2. The primary concentrated liquid is separated from the solid and liquid by the centrifuge under the plate discharge;

[0032] 3. The filtrate is concentrated twice through a four-effect concentrated evaporator, and the concentration of the concentrated solution is 50% of the dry basis content;

[0033] 4. The secondary concentrate is continuously mixed into the baked citric acid residue or sugar residue;

[0034] 5. The finished feed is obtained by mixing the ingredients for secondary drying. The protein content is 24.6%, and the moisture content is 12.5%, which meets the enterprise standard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com