Flux controllable anti-oxidation polyethersulfone nanofiltration membrane and preparation method thereof

A polyethersulfone, anti-oxidation technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of lack of anti-oxidation performance, limited application fields, and lack of flux of nanofiltration membranes , to achieve the effect of good interception capacity, simple preparation method and good anti-oxidation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

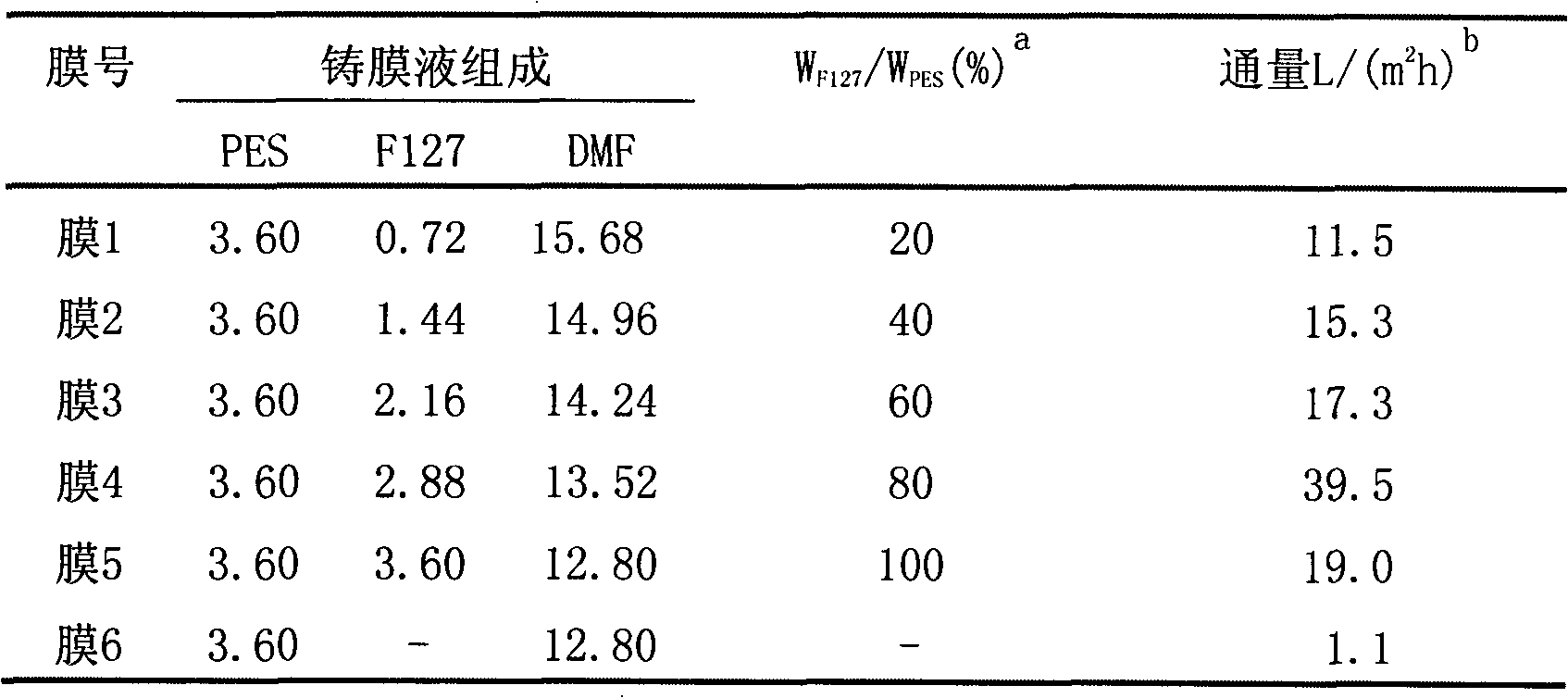

[0013] Preparation of controllable high-flux anti-oxidation polyethersulfone nanofiltration membrane (membrane 1):

[0014] Weigh 3.6g of polyethersulfone and 15.68g of N,N-dimethylformamide into a three-necked flask, heat in a constant temperature water bath at 60°C, stir and dissolve at 900r / min for about 0.5 hours. After completely dissolving, weigh 0.72g of Pluronic F127 with a molecular weight of 12600 as an additive, stir and dissolve at the same temperature for 3.5 hours, stir and mix evenly, and stand at 60°C for 5-12 hours for defoaming. After cooling to room temperature, pour the casting solution on a glass plate, scrape the film with a metal scraper, place it in the air for 10-30 seconds, put it in a water bath to solidify to form a film, soak it in deionized water for 24 hours, and dry it naturally for 24 hours. hours, and then immersed in deionized water for more than 12 hours to obtain a controllable high-flux anti-oxidation polyethersulfone nanofiltration membra...

Embodiment 2

[0017] Preparation of controllable high-flux polyethersulfone nanofiltration membrane (membrane 2):

[0018] Weigh 3.6g of polyethersulfone and 14.96g of N,N-dimethylformamide into a three-neck flask, heat in a constant temperature water bath at 60°C, stir and dissolve at 900r / min for about 0.5 hours. After completely dissolving, weigh 1.44g of Pluronic F127 with a molecular weight of 12600 as an additive, stir and dissolve at the same temperature for 3.5 hours, stir and mix evenly, and stand at 60°C for 5-12 hours for defoaming. After cooling to room temperature, pour the casting solution on a glass plate, scrape the film with a metal scraper, place it in the air for 10-30 seconds, put it in a water bath to solidify to form a film, soak it in deionized water for 24 hours, and dry it naturally for 24 hours. hours, and then immersed in deionized water for more than 12 hours to obtain a controllable high-flux anti-oxidation polyethersulfone nanofiltration membrane.

[0019] The...

Embodiment 3

[0021] Preparation of controllable high-flux polyethersulfone nanofiltration membrane (membrane 3):

[0022] Weigh 3.6g of polyethersulfone and 14.24g of N,N-dimethylformamide into a three-neck flask, heat in a constant temperature water bath at 60°C, stir and dissolve at 900r / min for about 0.5 hours. After completely dissolving, weigh 2.16g of Pluronic F127 with a molecular weight of 12600 as an additive, stir and dissolve at the same temperature for 3.5 hours, stir and mix evenly, and stand at 60°C for 5 to 12 hours for defoaming. After cooling to room temperature, pour the casting solution on a glass plate, scrape the film with a metal scraper, place it in the air for 10-30 seconds, put it in a water bath to solidify to form a film, soak it in deionized water for 24 hours, and dry it naturally for 24 hours. hours, and then immersed in deionized water for more than 12 hours to obtain a controllable high-flux anti-oxidation polyethersulfone nanofiltration membrane.

[0023] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com