System and method for extracting potassium sodium salt from garbage incineration fly ash

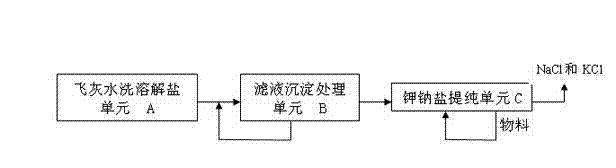

A waste incineration fly ash, potassium and sodium technology, which is applied in the field of extraction of potassium and sodium salts, can solve the problems of not seeing the extraction of potassium and sodium salts, and achieve the effects of benefiting subsequent product development, reducing the use of labor, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

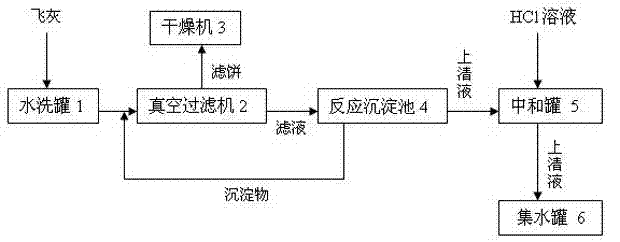

[0047] The steps of the process of washing the fly ash with dissolved salt are as follows:

[0048] A) Put water and the waste incineration fly ash in a mixing ratio of 2:1 into a water washing tank, stir and wash for 15 minutes, and then form a mixed slurry;

[0049] B) The mixed slurry obtained in step 1) is sent to a vacuum filter by a mud pump for filtration to obtain a filter cake with a water content of 25% and a filtrate containing salt; wherein, the filter cake is transported to a dryer by a belt for drying Afterwards stand-by; Send the salty filtrate into the reaction sedimentation tank in the filtrate precipitation treatment process to carry out precipitation treatment;

[0050] The steps of the filtrate precipitation treatment process are as follows:

[0051] C) Send the salt-containing filtrate into the reaction sedimentation tank, and at the same time add chemical agents to react with the filtrate to precipitate for 3 hours, and then separate the precipitate and ...

example 2

[0062] Fly ash washing dissolved salt process step is basically the same as example 1, and its difference is:

[0063] The weight ratio of water to waste incineration fly ash is 3:1; the stirring and washing time is 30 minutes;

[0064] The filtrate precipitation treatment procedure step is basically identical with example 1, and its difference is:

[0065] Add 80 grams of sodium sulfide and 210 grams of ferrous sulfate in every ton of salt-containing filtrate; the mass ratio of the added amount of 5% HCl solution to the supernatant is 1: 100.

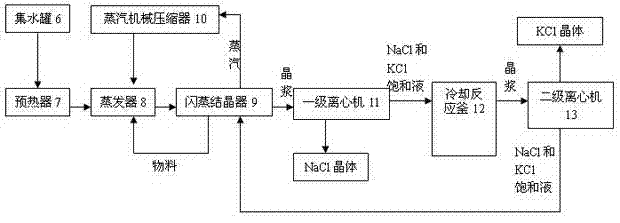

[0066] Potassium sodium salt purification procedure step is basically identical with example 1, and its difference is:

[0067] Step 2) After the material entering the evaporator evaporates and absorbs heat, the temperature rises to 105°C, and then enters the flash crystallizer;

[0068] Step 3) The material entering the flash crystallizer evaporates instantly under the negative pressure environment of 0.05Mpa in the flash crystalliz...

example 3

[0071] Fly ash washing dissolved salt process step is basically the same as example 1, and its difference is:

[0072] The weight ratio of water to waste incineration fly ash is 2:1; the stirring and washing time is 20 minutes;

[0073] The filtrate precipitation treatment procedure step is basically identical with example 1, and its difference is:

[0074] Add 60 grams of sodium sulfide and 170 grams of ferrous sulfate in every ton of salt-containing filtrate; the mass ratio of the added amount of 5% HCl solution to the supernatant is 1:80.

[0075] Potassium sodium salt purification procedure step is basically identical with example 1, and its difference is:

[0076] Step 2) The temperature of the material entering the evaporator rises to 104°C after evaporating and absorbing heat, and then enters the flash crystallizer;

[0077] Step 3) The material entering the flash crystallizer evaporates instantly under the negative pressure environment of 0.03Mpa in the flash crystalli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com