Method for treating excess sludge

A technology for excess sludge and treatment methods, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc., can solve problems affecting urban environmental sanitation, large land occupation, and environmental secondary Pollution and other issues, to achieve the effect of final disposal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

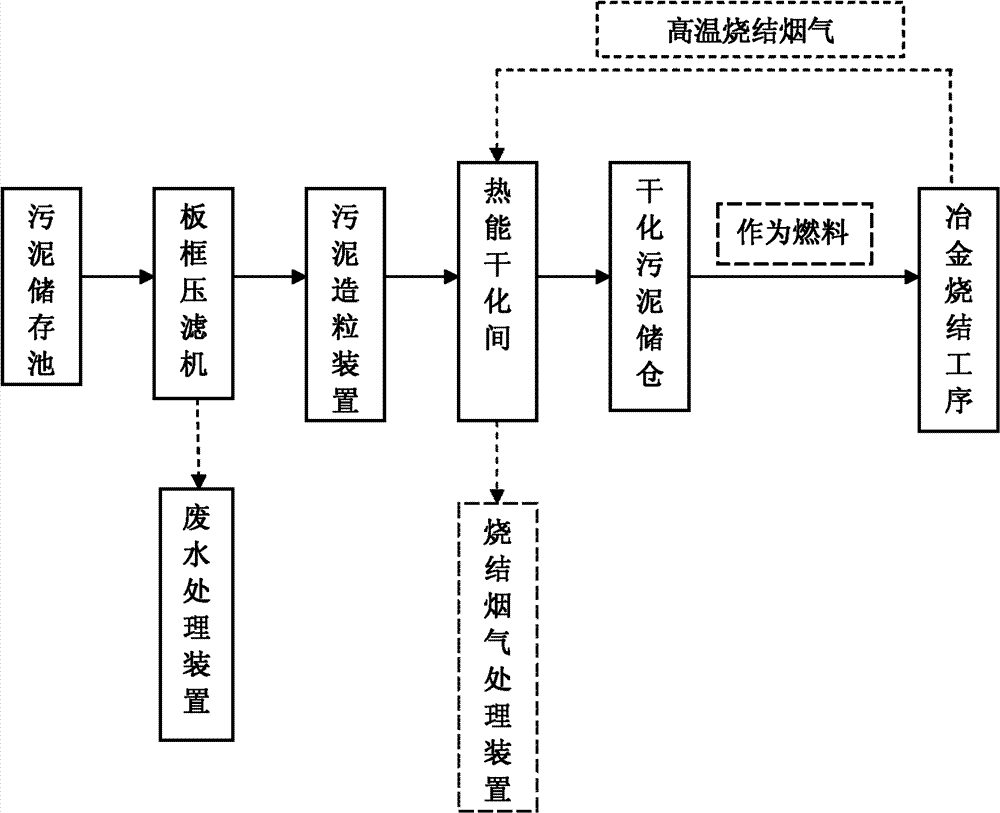

Image

Examples

Embodiment 1

[0016] The moisture content of the excess sludge taken from a sewage treatment plant is 85.2%, and it is transported into the plate and frame filter press, and the hydraulic station provides the plate and frame filter press with a pressing pressure of 25MPa. The sludge particles are trapped in the filter chamber to form semi-dried sludge cake, and the filtrate is collected by the collection device and returned to the sewage treatment system. The moisture content of the obtained semi-dried sludge cake was 43.7%. The semi-dried sludge cake is transported into the sludge granulation device through the mud cake conveyor, and the average particle size of the sludge particles is 3.8mm.

[0017] The sludge particles are laid flat in the thermal drying room, and the metallurgical sintering flue gas with a temperature of about 150°C is introduced. During the drying process, mechanically turning the sludge particles is used to accelerate the drying, and at the same time, the humidity i...

Embodiment 2

[0019] The excess sludge taken from a sewage treatment plant with a moisture content of 82.6% is transported into the plate and frame filter press, and the hydraulic station provides the plate and frame filter press with a pressing pressure of 35MPa. The sludge particles are trapped in the filter chamber to form semi-dried sludge cake, and the filtrate is collected by the collection device and returned to the sewage treatment system. The moisture content of the obtained semi-dried sludge cake was 41.5%. The semi-dried sludge cake is transported into the sludge granulation device through the mud cake conveyor, and the average particle size of the sludge particles is 4.3 mm.

[0020] The sludge particles are laid flat in the thermal drying room, and the temperature of the metallurgical sintering flue gas introduced is about 100 °C. During the drying process, mechanically turning the sludge particles is used to accelerate the drying, and at the same time, the humidity in the the...

Embodiment 3

[0022] The excess sludge from a sewage treatment plant with a moisture content of 82.6% is transported to the plate and frame filter press, and the hydraulic station provides the plate and frame filter press with a pressing pressure of 45MPa. The sludge particles are trapped in the filter chamber to form semi-dried sludge cake, and the filtrate is collected by the collection device and returned to the sewage treatment system. The moisture content of the obtained semi-dried sludge cake was 41.5%. The semi-dried sludge cake is transported into the sludge granulation device through the mud cake conveyor, and the average particle size of the sludge particles is 4.3mm.

[0023] The sludge particles are laid flat in the thermal drying room, and the temperature of the incoming metallurgical sintering flue gas is about 180°C. During the drying process, mechanically turning the sludge particles is used to accelerate the drying, and at the same time, the humidity in the thermal drying ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com