Process for co-processing organic waste liquid through oxygen-enriched side-blown bath smelting furnace

A molten pool smelting furnace and organic waste liquid technology, which is applied to the improvement of process efficiency, incinerator, indirect carbon dioxide emission reduction, etc., to achieve the effects of high heat recovery efficiency, increased heat transfer, and increased flue gas enthalpy

Pending Publication Date: 2022-04-26

杭州网新晟致环境有限公司

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, there is no explanation on the use method of liquid organic waste and the limitation of hazardous elements

Method used

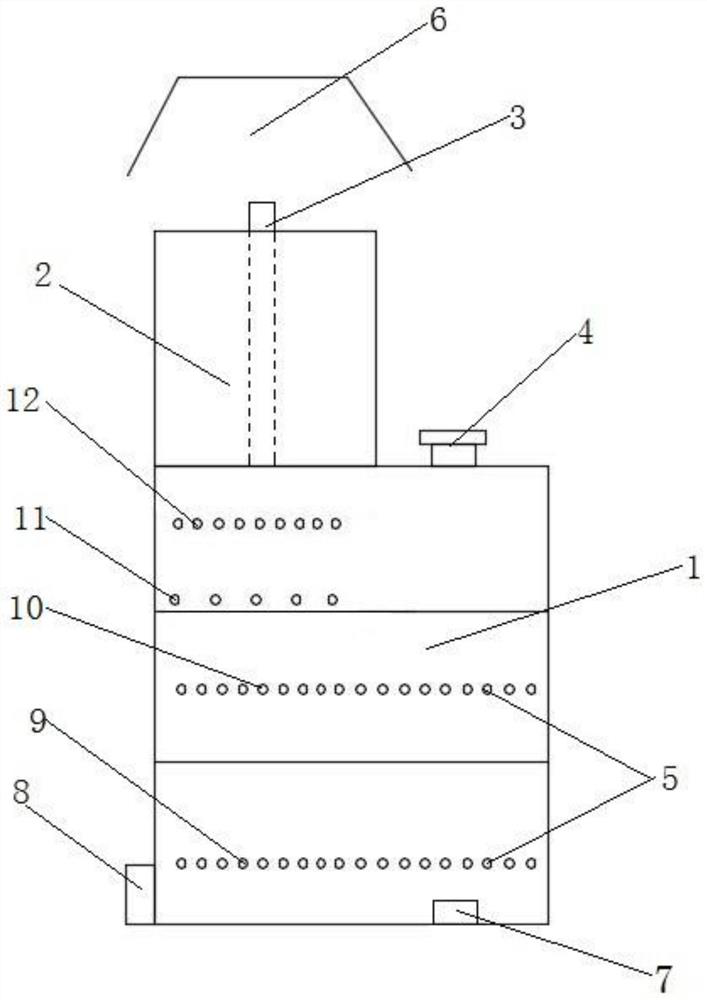

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

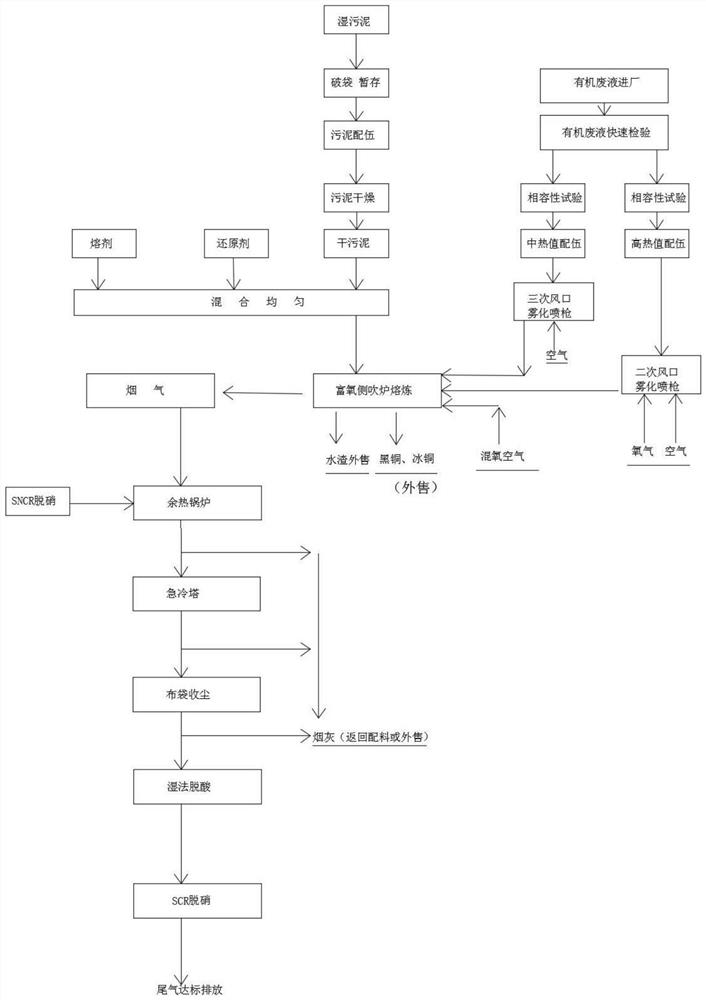

[0057] The organic waste liquid used covers the following limited parameters: PH 5~10, calorific value >3000kcal / kg, H2O<45%

[0058] After the organic waste liquid enters the factory, waste mineral oil, coal tar, waste organic flux, etc. are stored in their respective storage tanks according to the comparison results of pH value and calorific value;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to a process for co-processing organic waste liquid by an oxygen-enriched side-blown molten pool smelting furnace, which comprises the following steps: while solid hazardous waste is processed by the oxygen-enriched side-blown molten pool smelting furnace, the organic waste liquid is incinerated, combustible components are incinerated to generate carbon dioxide and water, and the carbon dioxide and the water enter a flue gas processing process link along with main flue gas of the oxygen-enriched side-blown molten pool smelting furnace; selectively treated organic waste liquid not only contains high-calorific-value organic waste liquid, but also can be synchronously treated after compatibility, and oxygen-enriched air is added into a molten pool, so that the organic waste liquid is intensively combusted, and combustion heat release of the organic waste liquid is effectively utilized; organic waste liquid is matched and reasonably matched with a reducing agent, so that the temperature of a molten pool is kept in a stable interval, and the stable smelting process is ensured; meanwhile, if heavy metal is contained in the organic waste liquid, the organic waste liquid can be oxidized in the smelting process of the molten pool to enter a slag phase, general solid waste water quenched slag is formed after water quenching, and therefore recycling and harmless treatment of the organic waste liquid in the smelting process of the oxygen-enriched side-blown molten pool is achieved.

Description

technical field [0001] The invention relates to the field of environmental protection, in particular to a process for co-processing organic waste liquid with an oxygen-enriched side-blown molten pool smelting furnace. Background technique [0002] Organic waste liquid refers to waste mineral oil or waste liquid containing waste mineral oil with different calorific values, waste organic solvent, oil-water or hydrocarbon-water mixture or emulsion, and waste containing organic halides and other types of hazardous waste. [0003] The composition of organic waste liquid is complex, the calorific value varies greatly, and it contains elements such as C, H, S, N, and heavy metals. The organic waste liquid listed as hazardous waste in the national hazardous waste list must be disposed of in an environmentally friendly manner, otherwise it will cause harm to the environment. Secondary pollution. [0004] There are many types of organic waste liquids, large quantities, and different ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F23G7/04F23G5/50F23J15/02F23J15/06C22B7/00

CPCF23G7/04F23G5/50F23J15/02F23J15/025F23J15/06C22B7/001Y02E20/34Y02E20/30Y02P10/20

Inventor 蒋平吕天勇

Owner 杭州网新晟致环境有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com