Method for modifying benzoxazine resin

A technology of benzoxazine and resin, which is applied in the field of modified benzoxazine resin, can solve the problems of polluting the environment and not being widely and efficiently used, and achieves the effect of low curing temperature and maintaining excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Weigh 100g industrial alkali lignin into a 500mL beaker, add 1% dilute sulfuric acid and stir for 30 minutes, then filter, wash the sulfuric acid-treated alkali lignin 3 times with water, the washing liquid is neutral, and the purified alkali lignin obtained at room temperature Let dry. Then put it in a vacuum oven at 60℃ to dry to constant weight, and store in a desiccator.

Embodiment 2

[0026] Add aniline (1mol) and paraformaldehyde (1mol) into a 250mL four-necked flask equipped with a thermometer, agitator, condenser, and dripping device. Stir evenly, then add toluene and raise the temperature to 100°C and stir for 2 hours, then cool down again. Phenol (1mol) or bisphenol A (0.5mol) and paraformaldehyde (1mol) were added, and the temperature was raised to 100°C while stirring to continue stirring for 1 hour. After the reaction is finished, it is filtered and dried after cooling, dissolved with ether, washed with sodium hydroxide solution 3 times, and washed 3 times with water. After drying with magnesium sulfate, the ether is removed with a rotary evaporator to obtain phenol monobenzoxazine monomer (PAF), or double Phenol A type bisbenzoxazine monomer (BAF). NMR analysis results: 1 H-NMR (DMSO, ppm): 4.0 (2H, Ar-CH 2 -N), 4.76(2H, O-CH 2 -N-), 1.0~1.2(3H, -CH 3 ), 3.7(2H, O-CH 2 -). The peak curing temperature measured by DSC is 254°C for PAF and 261°C for B...

Embodiment 3

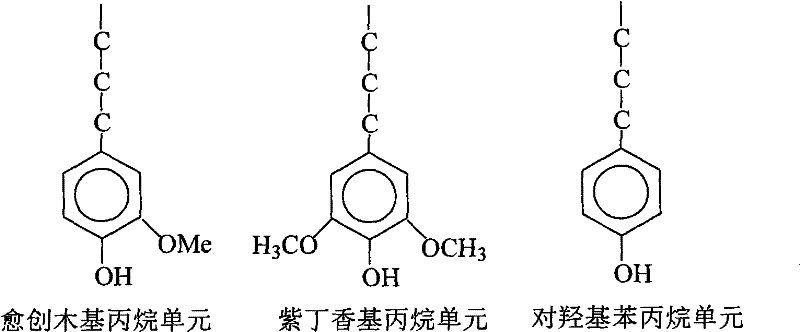

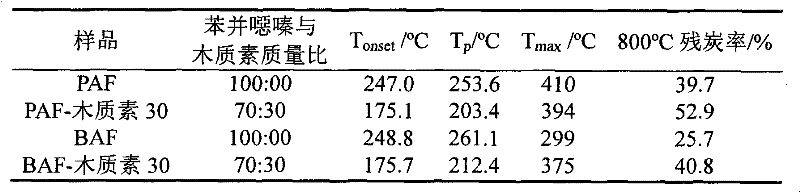

[0028] Put 120g pyridine into a 500mL three-necked flask, weigh 30g alkali lignin under stirring, and add 70g phenol monobenzoxazine monomer PAF or bisphenol A dibenzoxazine monomer BAF after the lignin is dissolved, continue Stir for 30 minutes, pour out the mixture in a petri dish, put it in a vacuum oven to dry, a part of the solid obtained is used for DSC to test the curing start temperature T onset And peak temperature T p , The other part is cured in an electric oven according to the process of 120℃ / 2h+140℃ / 2h+160℃ / 6h and then used TGA to test the maximum thermal weight loss rate temperature T of the polybenzoxazine resin max And 800℃ residual carbon rate. The specific results are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com