Method for additionally applying carbon dioxide air fertilizer to warm-house booth through agricultural organic waste fermentation

A technology of organic waste and carbon dioxide, which is applied in the production of fertilizers from carbon dioxide, the preparation of organic fertilizers, and organic fertilizers. Conducive to the popularization and application and the effect of improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

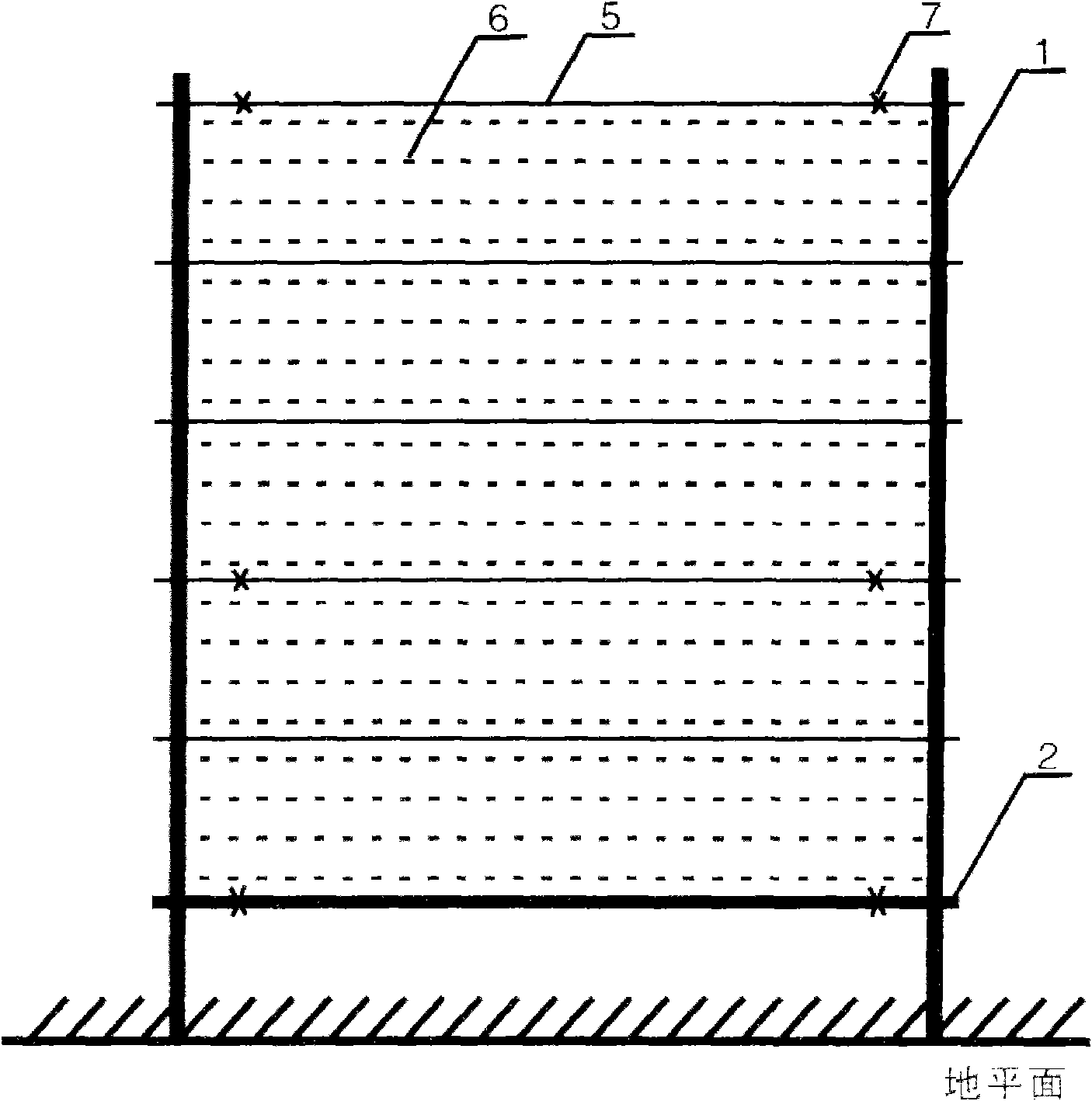

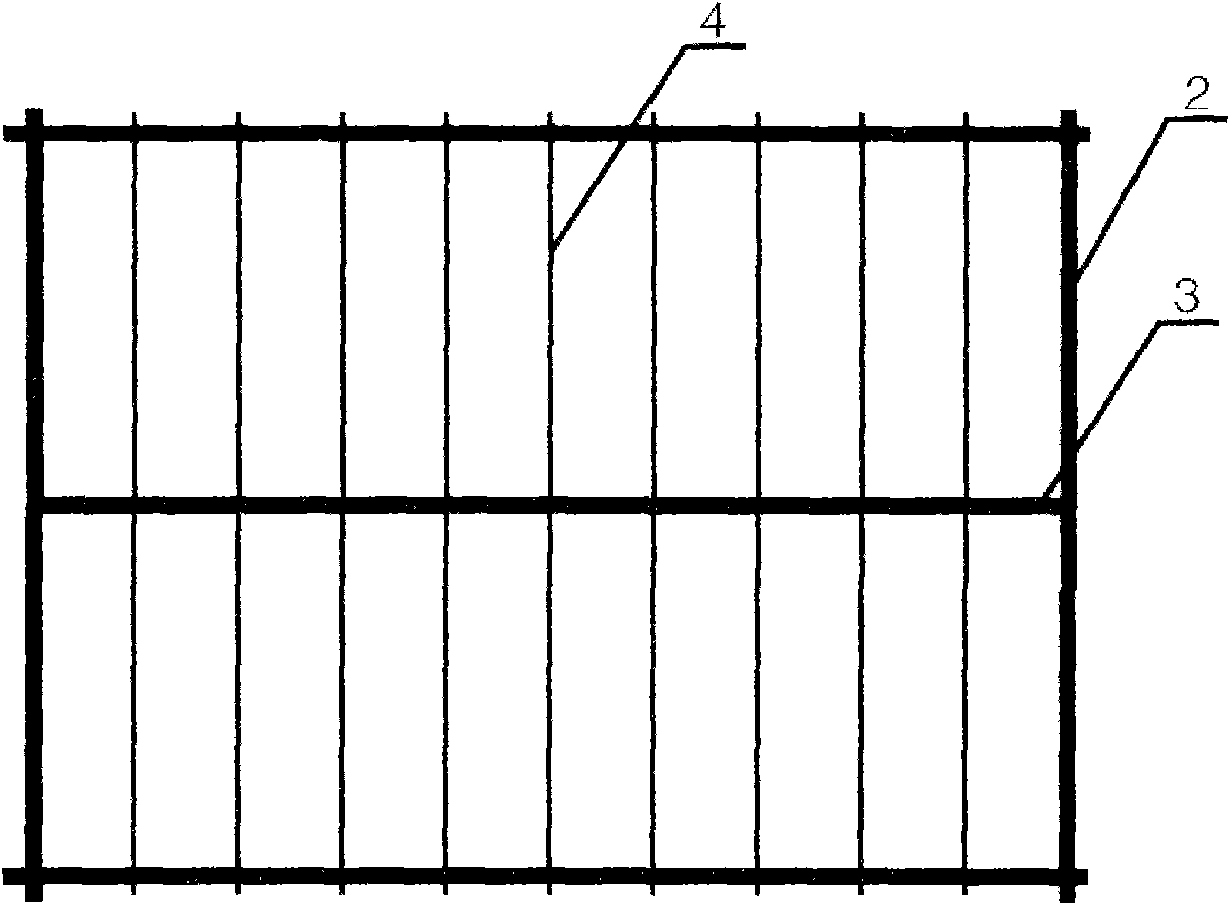

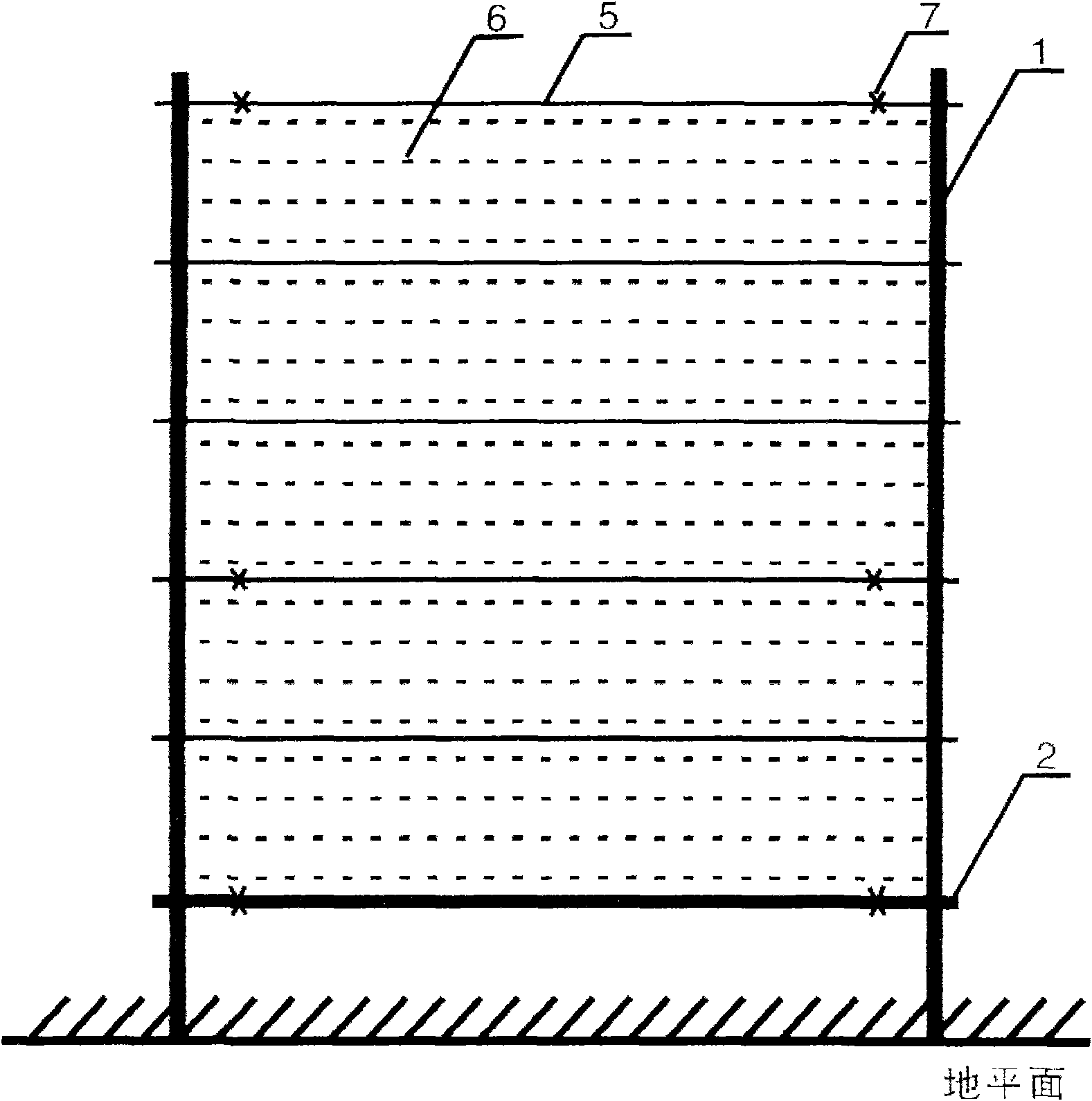

[0024] 1. Make a simple fermentation cylinder:

[0025] Bury four 145cm-long fixed piles vertically into the soil, with a horizontal spacing of 105cm, a vertical spacing of 95cm, and a depth of 20cm, and tamp them to ensure firmness. Set up a load-bearing pole parallel to the ground at a height of 20cm from the fixed pile to the ground, two in the horizontal and vertical directions, and a pressure-bearing pole in the middle of the two vertical poles to form a "day"-shaped bottom plane of the fermentation cylinder. Lay longitudinal reinforcing rods with a distance of 8-10 cm between the rods to prevent leakage of the fermentation substrate. Set up a connecting rod every 20cm above the self-supporting rod of the fixed pile, and then surround the connecting rod with a wire mesh with a mesh diameter below 8cm, a width of 90cm-100cm, and a length of about 4m from the inner diameter. Secure with thin wire. Finally, use a plastic film of the same size to surround the barbed wire in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com