Bacterial strain for producing gel breaking enzyme and application thereof

A gel-breaking enzyme and bacterial strain technology, which is applied in the field of gel-breaking enzyme strains, can solve problems such as uncontrollable reactions, formation damage, and failure of fracturing construction, and achieve rapid and uniform viscosity reduction, high enzyme production efficiency, and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

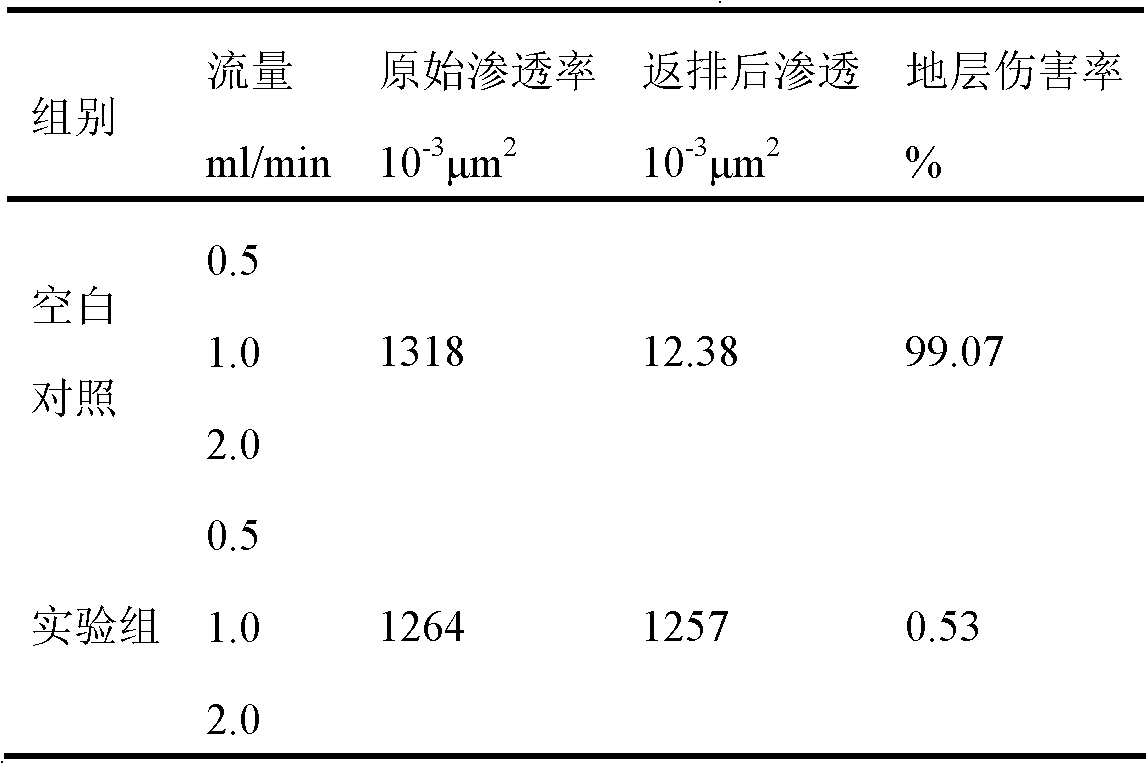

Examples

Embodiment 1

[0024] 1. Microbial fermentation

[0025] The screened strains are fermented. During the fermentation process, the fermentation conditions and medium components are firstly optimized. First, the optimum carbon source, nitrogen source, phosphorus source, sulfur source, trace element solution and pH of the fermentation medium are optimized. Factors such as fermentation mode, cycle (1-10 days), temperature (20°C-50°C) and inoculum amount (1.0%-10.0%) were optimized, and the above factors were optimized by measuring enzyme activity and gel breaking rate, and finally Determine the production medium and fermentation conditions of the fracturing fluid gel-breaking enzyme, and the yield of the gel-breaking enzyme obtained by the optimized fermentation is 240U / ml-270U / ml.

[0026] In the fermentation process of the gel breaking enzyme, three-stage fermentation is adopted. The seed liquid medium is determined as liquid LB medium, and the strain is firstly subjected to secondary expansio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com