Antibacterial fabric and preparing method thereof

A kind of antibacterial fabric and fabric technology, applied in the direction of textiles, papermaking, fiber treatment, etc., can solve the problems of difficult industrialization, cytotoxic graphene oxide and fabric cannot be connected, and achieve low cost, simple post-processing, antibacterial performance of washing resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 Modified polyethersulfone (PES) antibacterial fabric (fabric 1)

[0031] Put 5g of PES (weight-average molecular weight=410,000) fabric into deionized water and rinse 5 times. Immerse the rinsed PES fabric in an aqueous solution containing 0.5% (w / w) N, N'-methylene bisacrylamide for 24 hours until saturated adsorption; take out the fabric and use absorbent paper to absorb the surface solution and put it into negative pressure As a filter cloth in the filter, introduce 500 g of GO aqueous solution with a graphene oxide (GO) concentration of 0.1 mg / mL into the filter cup of the negative pressure filter, filter once at normal pressure, take out the fabric, and absorb the surface solution with absorbent paper Finally, it was placed in a cobalt source and irradiated to 1 kGy, then taken out, extracted with ethanol for 48 hours, and then vacuum-dried to constant weight to obtain an antibacterial fabric 1 containing GO, with a GO content of 1%.

[0032] Antibact...

Embodiment 1

[0033] Comparative example 1 blank polyethersulfone (PES) fabric (contrast 1)

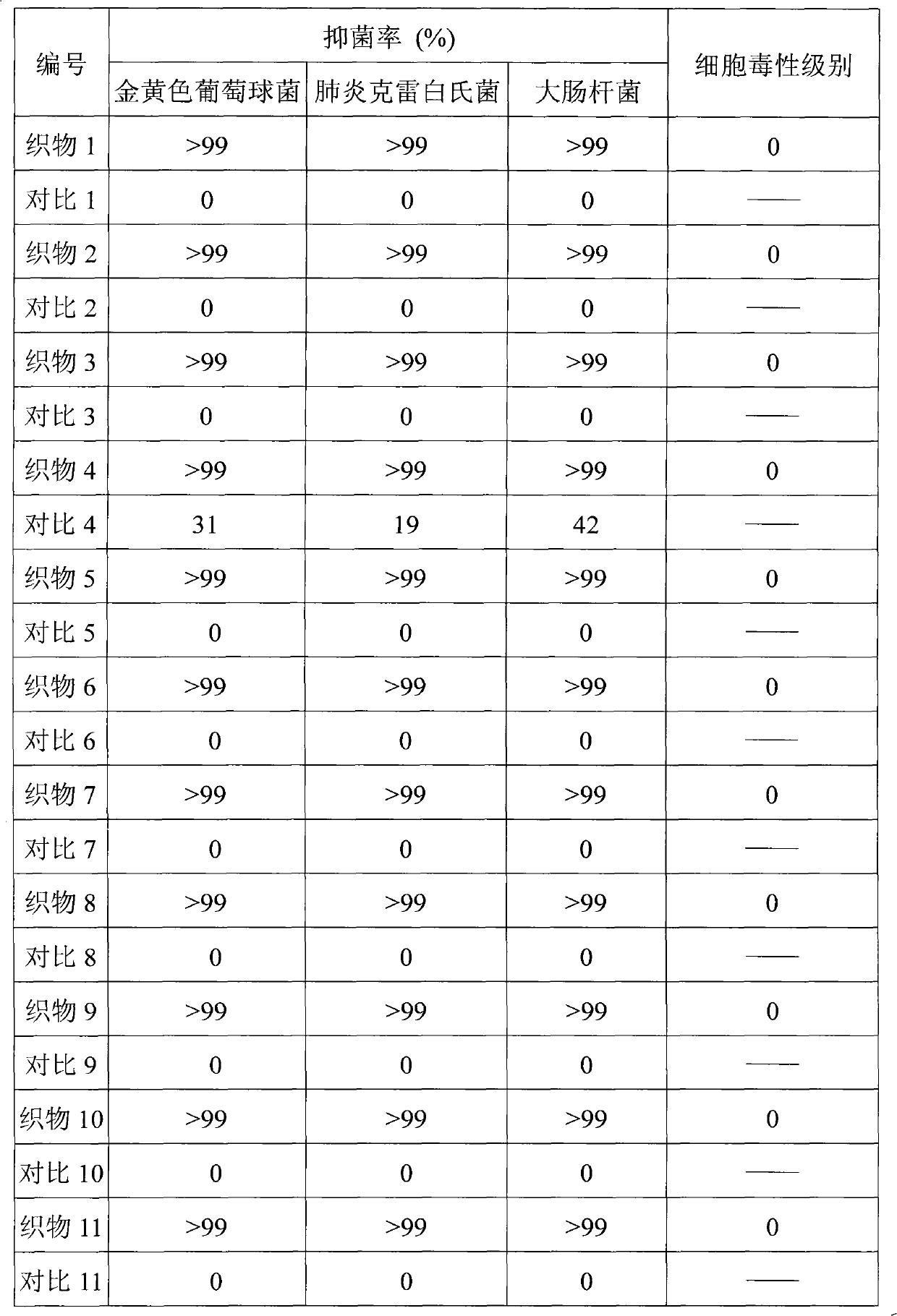

[0034] The antibacterial performance and cytotoxicity of the PES fabric before modification in Example 1 were tested according to the method of Example 1, and the test results are shown in Table 1.

Embodiment 2

[0035] Embodiment 2 modified antibacterial cotton fabric (fabric 2)

[0036] 5 g of natural cotton fabric was rinsed 5 times in deionized water. Soak the rinsed cotton fabric in methanol solution containing 2.5% (w / w) triallyl cyanurate for 36 hours until saturated adsorption; take out the fabric and use absorbent paper to absorb the surface solution and put it into negative pressure filtration In the container as a filter cloth, introduce 250 g of GO aqueous solution with a graphene oxide (GO) concentration of 2 mg / mL into the filter cup of the negative pressure filter, vacuum filter 3 times, take out the cotton cloth, and absorb the surface solution with absorbent paper, Put it into the cobalt source and irradiate it to 35kGy, take it out, extract it with ethanol for 48 hours, and then vacuum dry it to constant weight to obtain the antibacterial fabric 2 containing GO, with a GO content of 1.8%.

[0037] The antibacterial fabric 2 was washed 50 times according to the ACCTCC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com