Corrosion prevention method for a concrete bridge

A concrete and bridge technology, applied in bridges, bridge maintenance, bridge reinforcement, etc., can solve problems such as changing concrete performance, affecting bridge life, complex construction process, etc., to prolong construction time, prevent corrosion, and install and construct the effect of simple construction process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

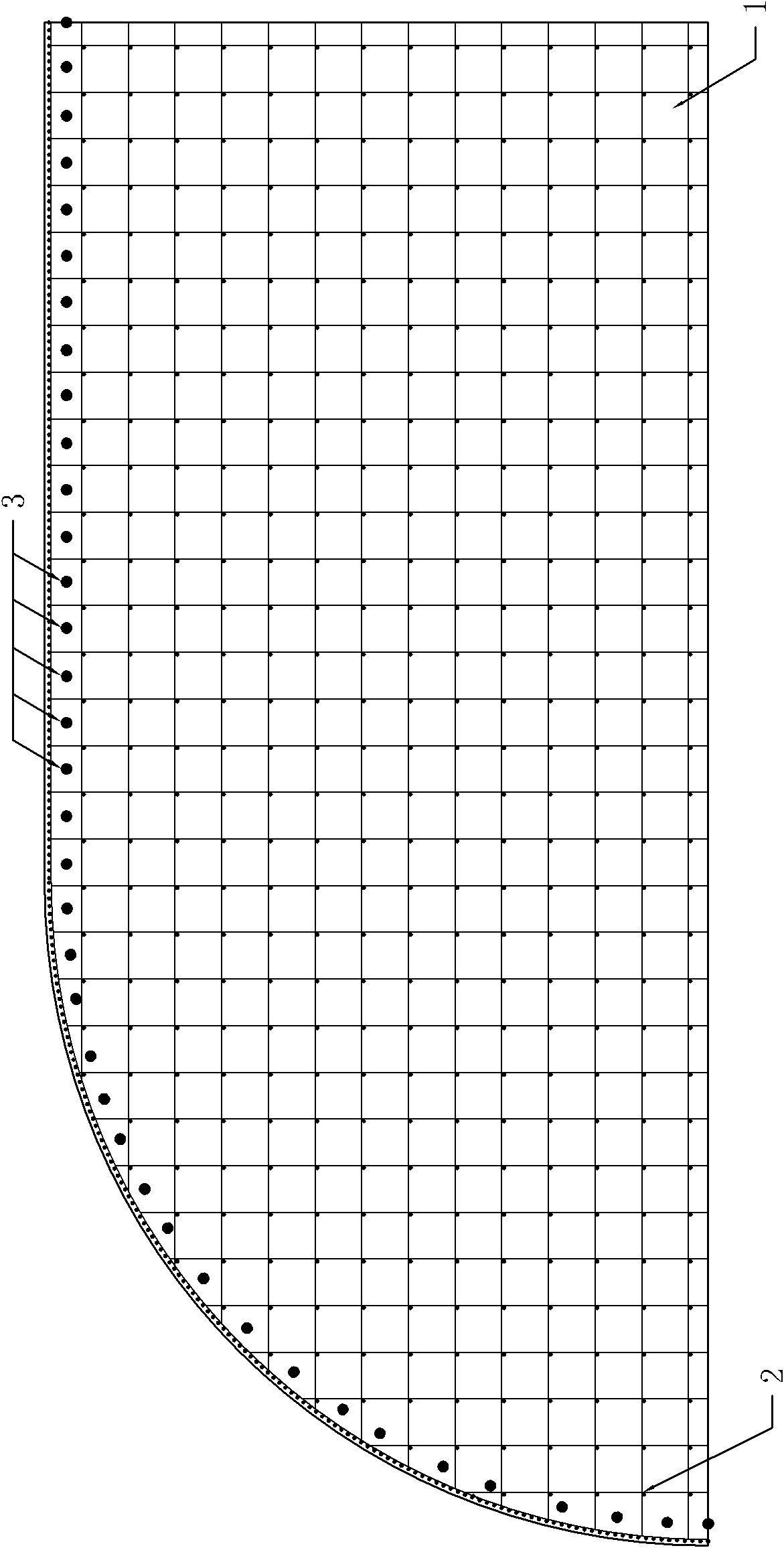

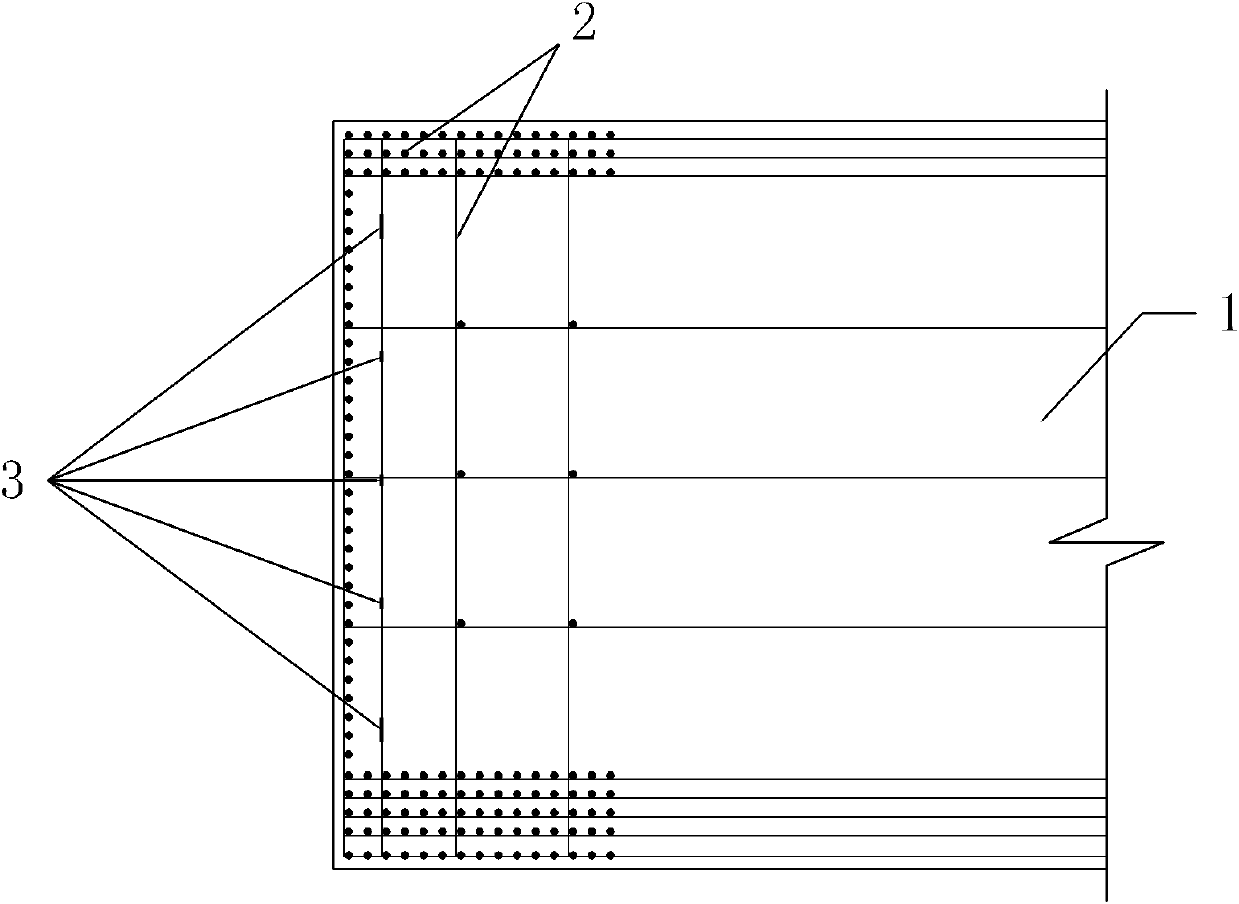

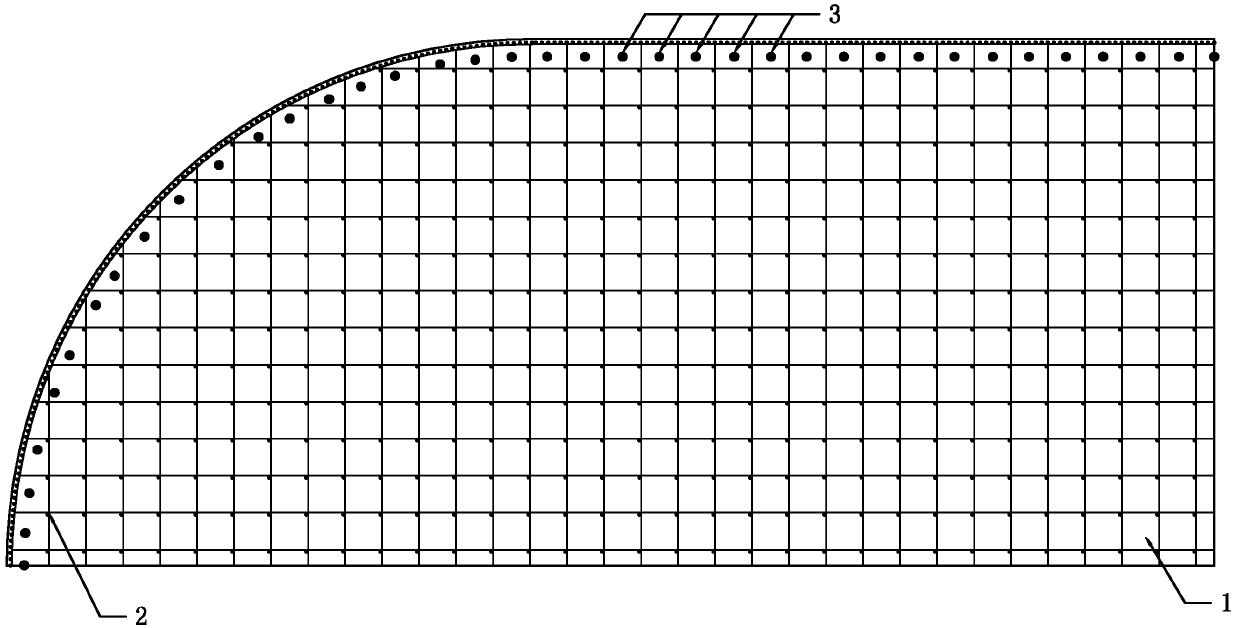

[0026] The present invention will be further described below in conjunction with the accompanying drawings. Such as figure 1 Shown, a kind of anticorrosion method of concrete bridge comprises the following steps:

[0027] A, a permanent auxiliary anode 3 is placed inside the steel bar 2 concrete 1, and a DC power supply is connected between the auxiliary anode 3 and the steel bar 2 as the cathode;

[0028] B. Connect the negative pole of the DC power supply to the steel bar 2, and the positive pole to the auxiliary anode 3;

[0029] C. Turn on the power supply so that the magnitude of the inflowing direct current is sufficient to force the anode reaction on the surface of the steel bar 2 to stop completely.

[0030] The auxiliary anode 3 of the present invention adopts an active titanium mesh belt, and its parameters are as follows: the width is 6.3 mm; the thickness is 0.6 mm; the substrate is titanium-based grade 1 ASTMB265; the anode coating is a noble metal oxide cataly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com