Accurate forming method for precise-casting turbine blade die cavity

A turbine blade and model technology, applied in the direction of casting molds, casting mold components, casting molding equipment, etc., can solve the problems of inaccurate design of mold cavity, low efficiency, long cycle, etc., to reduce design costs, high efficiency, and design short cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and provides detailed implementation methods and processes. But the scope of protection of the present invention is not limited to the following examples.

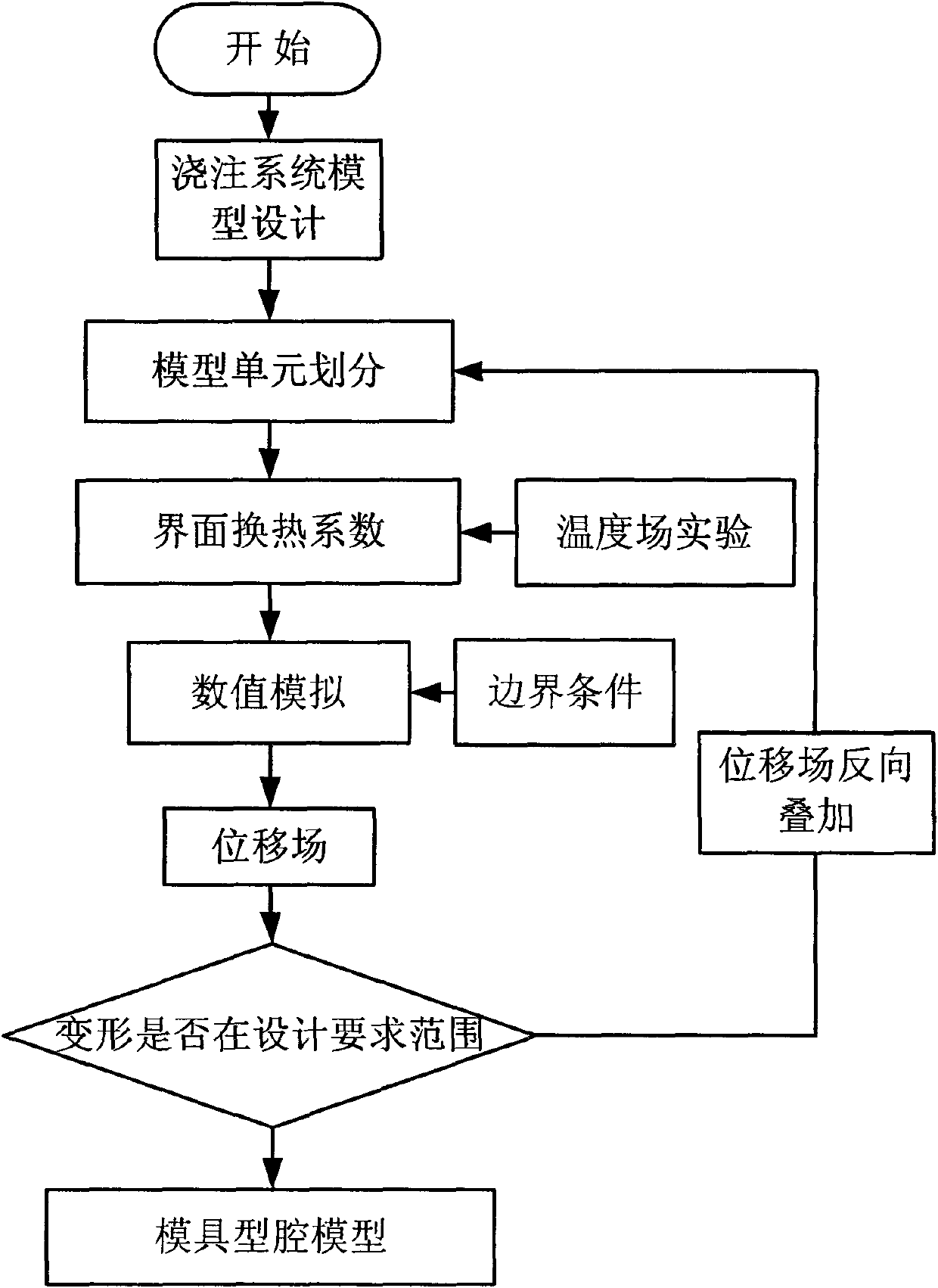

[0027] The design of the cavity of the shaping mold for producing a certain type of aviation turbine blade, the embodiment steps are as follows figure 1 Shown:

[0028] step 1

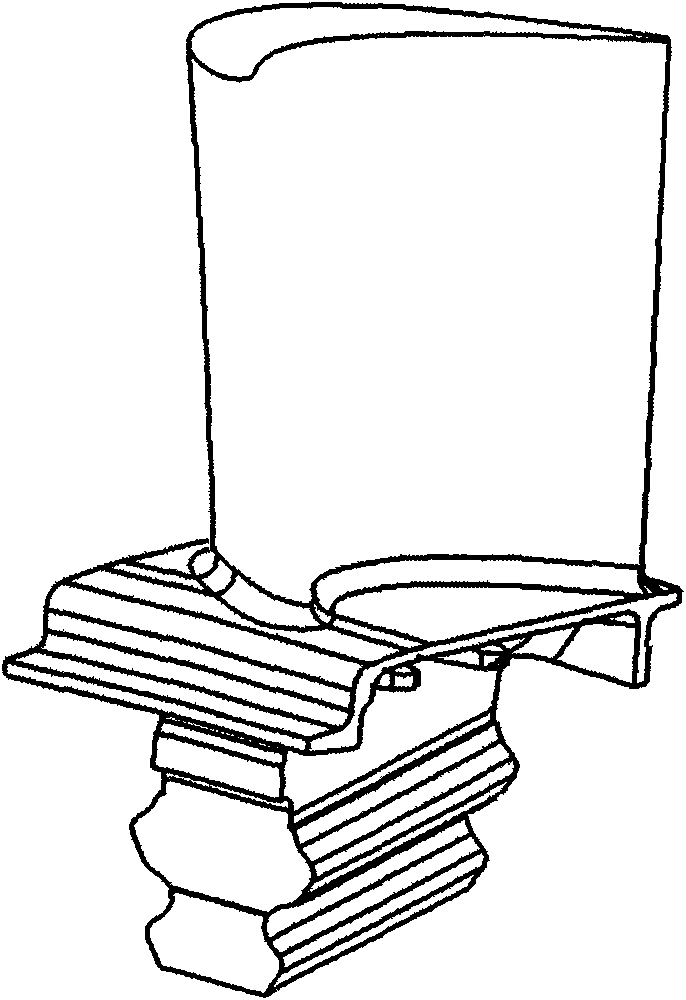

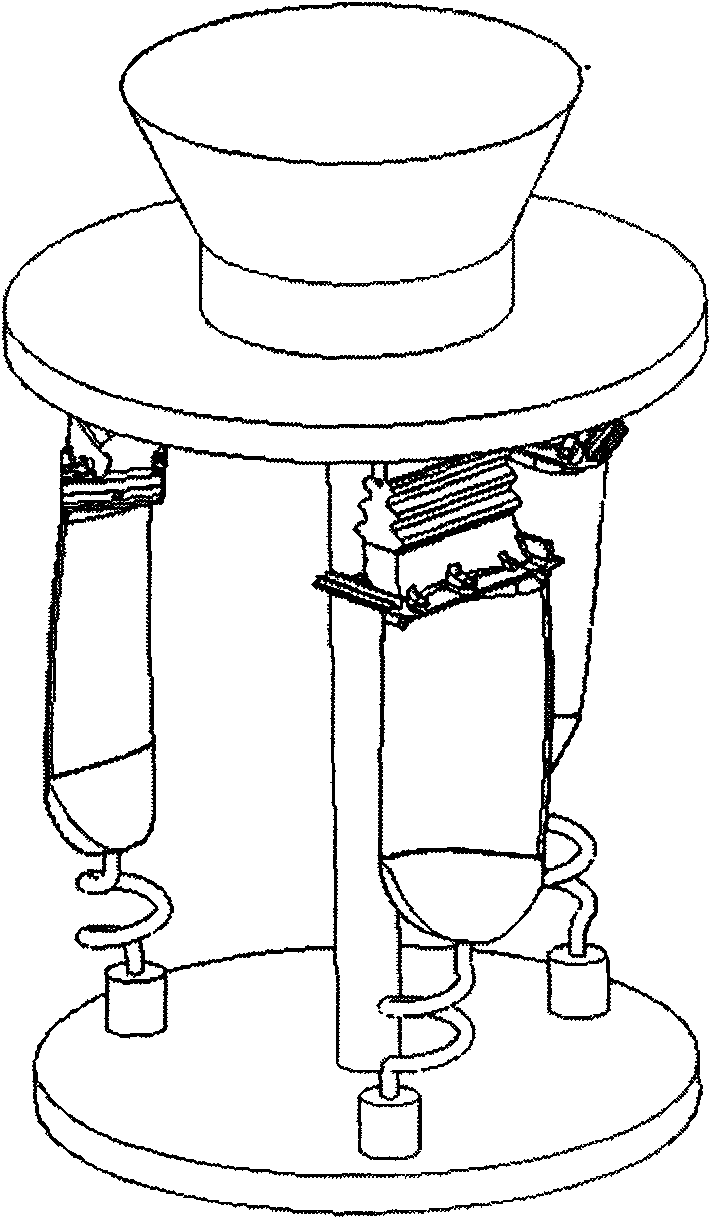

[0029] A certain type of turbine blade is used for numerical simulation, such as figure 2 shown. Its main parameters are blade body length 101mm, maximum chord length 59.21mm, maximum inscribed circle radius 5.67mm, leading edge radius 4.22mm, and trailing edge radius 1.27mm. The blade is made of the second generation single crystal superalloy DD6, and the mold shell is made of silica sand. According to casting feeding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com