Manufacturing method of pixel structure and pixel structure

A pixel structure and manufacturing method technology, which is applied in semiconductor/solid-state device manufacturing, optics, instruments, etc., can solve the problems of affecting the electrical performance of the pixel structure, insufficient adhesion between the pixel electrode and the dielectric layer, and peeling off of the pixel electrode.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

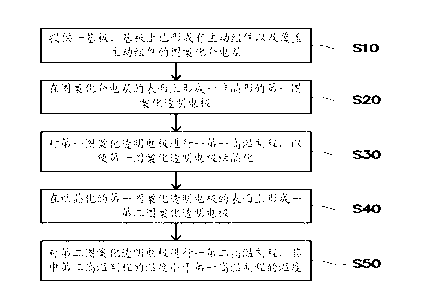

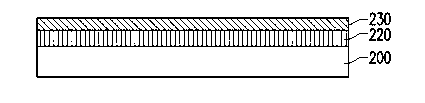

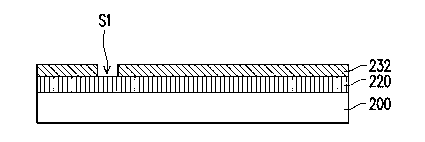

[0022] figure 1 It is a schematic flowchart of a manufacturing method of a pixel structure in a preferred embodiment of the present invention. Figure 2A to Figure 2F is a schematic cross-sectional view of a method for manufacturing a pixel structure in an embodiment of the present invention, and image 3 To take advantage of the aforementioned Figure 2A to Figure 2F An upper view of a pixel structure made by the method for making a pixel structure, wherein Figure 2F for correspondence image 3 Schematic cross-section along section line AA'.

[0023] Please refer to figure 1 , Figure 2A and image 3 , first provide a substrate 200, on which an active component 210 and a patterned dielectric layer 220 covering the active component 210 have been formed (step S10). The active component 210 is, for example, a thin film transistor, which includes a gate 212, a source 214 And the drain 216 , in this embodiment, the scanning line 218 is formed together during the process of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com