Preparation method of lithium ion battery carbon anode material with graphene-like structure

A technology of lithium ion battery and carbon negative electrode material, which is applied to battery electrodes, structural parts, circuits, etc., can solve the problems of poor high-rate discharge performance, easy safety, poor compatibility, etc., and achieves improved cycle performance, low cost, The effect of low carbonization temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

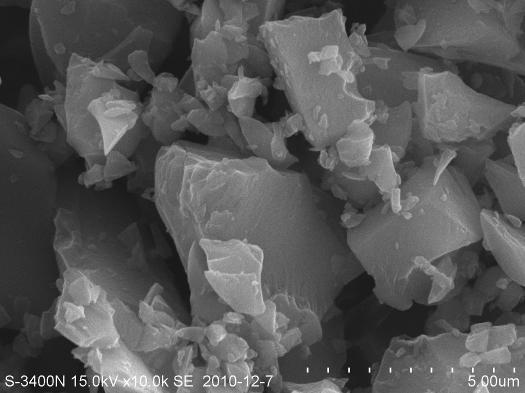

[0053] Stir 20g of 10% LPAN (molecular weight 1600) solution (mass percentage) at 120°C for 20 hours to form a microcyclized LPAN solution, heat-treat the microcyclized LPAN solution at 200~300°C for 10 hours to form a Thermally oxidized polyacrylonitrile oligomer (OPAN) solid with trapezoidal structure was ball-milled with a planetary ball mill at a ball-to-material ratio of 15:1, 400 rad / min for 8 h, and after discharge, sieved and dried at room temperature. Under the protection of argon, calcined at 600°C for 4 h, and carbonized to obtain an amorphous carbon anode material for lithium-ion batteries, whose structure is as follows: figure 1 As shown, it is amorphous carbon. Active material: acetylene black: adhesive is equal to the ratio (mass percentage) of 85:5:10 to make an electrode sheet, with lithium sheet as the positive electrode, Cellgard 2300 porous membrane as the separator, and 1mol??L -1 The mixed solution of LiPF6 / EC+DMC (volume ratio 1:1) was used as the elect...

Embodiment 2

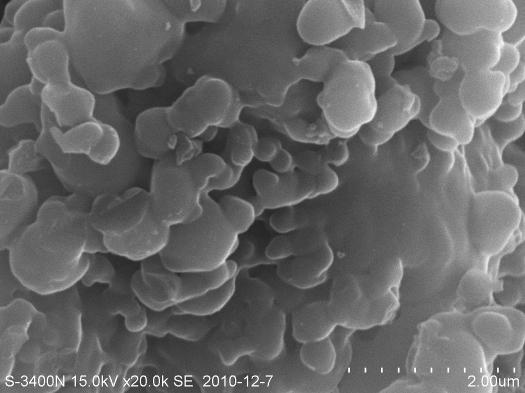

[0055] Stir 20g of 10% LPAN (molecular weight 1600) solution (mass percentage) at 120°C for 20 hours to form a microcyclized LPAN solution, heat-treat the microcyclized LPAN solution at 200~300°C for 10 hours to form a Thermally oxidized polyacrylonitrile oligomer (OPAN) solid with trapezoidal structure was ball-milled with a planetary ball mill at a ball-to-material ratio of 15:1, 400 rad / min for 8 h, and after discharge, sieved and dried at room temperature. Under the protection of argon, calcined at 900 °C for 4 h, and carbonized to obtain an amorphous lithium-ion battery carbon anode material, whose structure is as follows: figure 2 As shown, it is amorphous carbon. Active material: acetylene black: adhesive is equal to the ratio (mass percentage) of 85:5:10 to make an electrode sheet, with lithium sheet as the positive electrode, Cellgard 2300 porous membrane as the separator, and 1mol??L -1 The mixed solution of LiPF6 / EC+DMC (volume ratio 1:1) was used as the electroly...

Embodiment 3

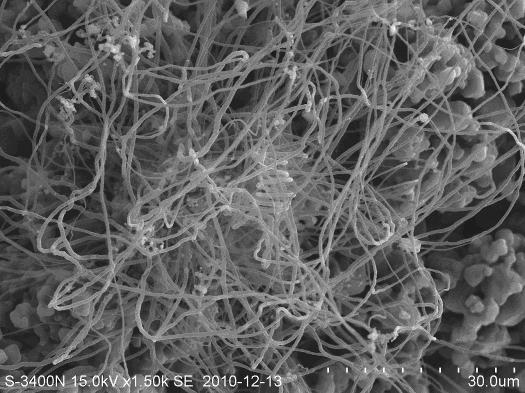

[0057] Stir 20g of 10% LPAN (molecular weight 1600) solution (mass percentage) at 120°C for 20 hours to form a microcyclized LPAN solution, heat-treat the microcyclized LPAN solution at 200~300°C for 16 hours to form a Thermally oxidized polyacrylonitrile oligomer (OPAN) solid with trapezoidal structure was ball-milled with a planetary ball mill at a ball-to-material ratio of 15:1, 400 rad / min for 8 h, and after discharge, sieved and dried at room temperature. Under the protection of argon, calcined at 1100°C for 4 h, and carbonized to obtain carbon anode materials for lithium ion batteries with various carbon structures (graphene-like structure, amorphous structure and carbon nanotubes). image 3 and Figure 4 As shown, there are both amorphous carbon structures and carbon nanotubes. The Raman spectrum of the carbon nanotubes in the resulting product is as Figure 7 As shown, there are both D peaks of amorphous carbon and G peaks and G' peaks of graphitic carbon in the prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com