Polycarboxylate-based water-reducing agent with effect of inhibiting corrosion of steel bars and preparation method thereof

A technology of polycarboxylate and steel bar corrosion, which is applied in the field of concrete admixtures in building materials, can solve the problems of unsatisfactory water-reducing effect and anti-rust effect, complex synthesis process, etc., and achieve good product stability and simple preparation process Easy to operate, high water reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

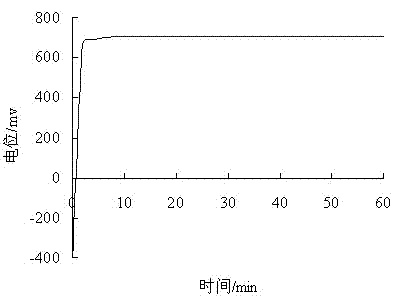

Image

Examples

Embodiment 1

[0023] Refer to the following steps to prepare a polycarboxylate water reducer with the function of inhibiting steel corrosion:

[0024] The first step of polymerization reaction: Add 238 parts of water into the reaction kettle, raise the temperature to 60°C, and then add 120 parts of modified polyether with a molecular weight of M=2400, stir to fully dissolve it, and then raise the temperature to a reaction temperature of 90°C ℃, within 4 hours, drop 75 parts of 10% ammonium persulfate aqueous solution, 36 parts of 50% acrylic acid and methacrylic acid aqueous solution (the molar ratio of acrylic acid and methacrylic acid is 4:1), and react at a constant temperature of 90 ℃ After 2 hours, it was naturally cooled to 40°C to obtain a modified ether polycarboxylate water reducer.

[0025] The second step of pH adjustment: under stirring, add 2-diethylaminoethanol, 2-amino-2-methyl-1 - 47 parts of propanol were adjusted for pH value, reacted at 40°C for 40 minutes, and then cool...

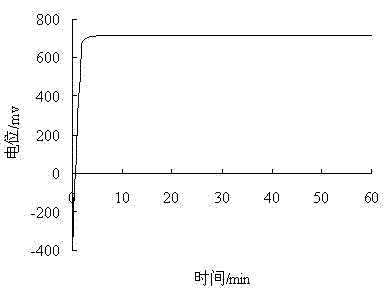

Embodiment 2

[0028] Refer to the following steps to prepare a polycarboxylate water reducer with the function of inhibiting steel corrosion:

[0029] The first step of polymerization reaction: Add 231 parts of water into the reaction kettle, raise the temperature to 60°C, and then add 120 parts of modified polyether with a molecular weight of M=2400, stir to fully dissolve it, and raise the temperature to a reaction temperature of 90°C ℃, 75 parts of 10% ammonium persulfate aqueous solution and 32.4 parts of 50% acrylic acid aqueous solution were added dropwise within 4 hours, and reacted at 90℃ for 2 hours, then naturally cooled to 40℃ to obtain modified ether polycarboxylic acid system Water reducing agent.

[0030] The second step of pH value adjustment: under stirring, add 80% of 3-amino-1-propanol and 2-cyclohexylaminoethanol to the modified ether polycarboxylate water reducer obtained in the first step of polymerization reaction. Adjust the pH value of each part, react at 40°C for 4...

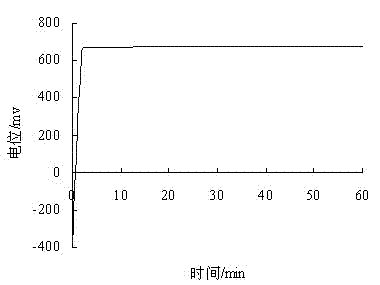

Embodiment 3

[0033] Refer to the following steps to prepare a polycarboxylate water reducer with the function of inhibiting steel corrosion:

[0034] The first step of polymerization reaction: add 178 parts of water to the reaction kettle, raise the temperature to 60°C, then put in 100 parts of modified polyether with molecular weight M=2000, stir to make it fully dissolve, then raise the temperature to the reaction temperature of 90°C ℃, within 4 hours, drop 75 parts of 10% ammonium persulfate aqueous solution, 23.7 parts of 50% acrylic acid and methacrylic acid aqueous solution (the molar ratio of acrylic acid and methacrylic acid is 1:1), and react at a constant temperature of 90 ℃ After 2 hours, it was naturally cooled to 40°C to obtain a modified ether polycarboxylate water reducer.

[0035] The second step of pH adjustment: under stirring, add 2-amino-2-methyl-1-propanol, 3-amino - 30 parts of 1-propanol were adjusted for pH value, reacted at 40°C for 40 minutes, and then cooled to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com