Composite high-temperature-resistant wave-absorbing coating material and preparation method of wave-absorbing coating

A wave-absorbing coating and high-temperature-resistant technology, which is applied in the field of high-temperature-resistant dielectric electromagnetic wave-absorbing coating and its preparation, can solve the problems of poor matching performance of high-temperature resistance of ceramic aggregates, and achieve low cost and good heat resistance Excellent performance and operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

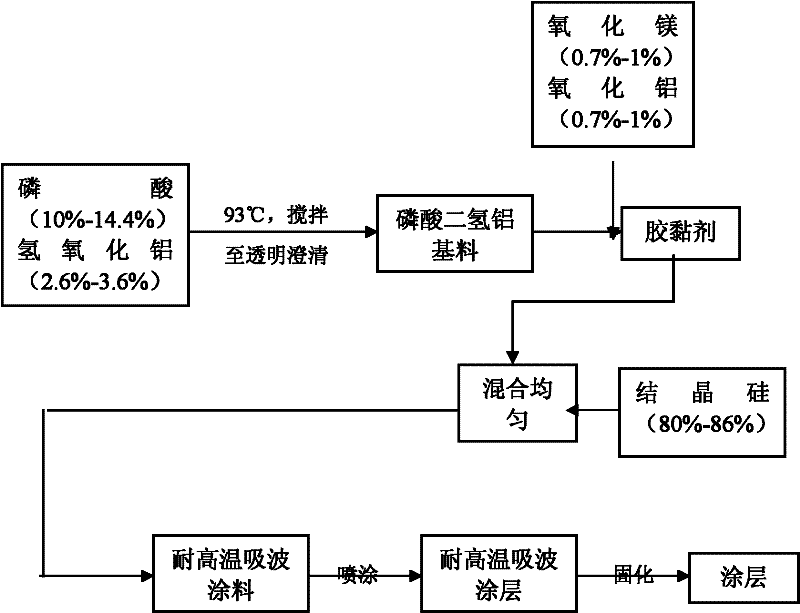

Method used

Image

Examples

specific Embodiment approach 1

[0026] A high temperature resistant electromagnetic wave absorbing coating, which is composed of aluminum dihydrogen phosphate, magnesium oxide, aluminum oxide and crystalline silicon, and the components are mutually fused according to the following mass percentages:

[0027] Aluminum dihydrogen phosphate 18

[0029] Aluminum oxide 1

[0030] Crystalline silicon 80

[0031] Spray on an aluminum plate with a size of (20*20 cm) by spraying method and form a high temperature resistant wave-absorbing coating with a thickness of 1.3 mm.

[0032] The high temperature resistant electromagnetic wave absorbing coating can be obtained through the above preparation steps. At this time, the performance of the coating is stable at 800° C., and its reflectivity is lower than -5 dB at 4 GHz to 8 GHz, and the peak value reaches -32 dB.

specific Embodiment approach 2

[0033] A high temperature resistant electromagnetic wave absorbing coating, which is composed of aluminum dihydrogen phosphate, magnesium oxide, aluminum oxide and crystalline silicon, and the components are mutually fused according to the following mass percentages:

[0034] Aluminum dihydrogen phosphate 14.4

[0035] Magnesium oxide 0.8

[0036] Aluminum oxide 0.8

[0037] Crystalline silicon 84

[0038] Spray on an aluminum plate with a size of (20*20 cm) by spraying method and form a high temperature resistant wave-absorbing coating with a thickness of 1.3 mm.

[0039] The high temperature resistant electromagnetic wave absorbing coating can be obtained through the above preparation steps. At this time, the performance of the coating is stable at 800° C., and its reflectivity is lower than -5 dB at 8 GHz to 12 GHz, and the peak value reaches -22 dB.

specific Embodiment approach 3

[0040] A high temperature resistant electromagnetic wave absorbing coating, which is composed of aluminum dihydrogen phosphate, magnesium oxide, aluminum oxide and crystalline silicon, and the components are mutually fused according to the following mass percentages:

[0041] Aluminum dihydrogen phosphate 12.6

[0042] Magnesium oxide 0.7

[0043] Aluminum oxide 0.7

[0044] Crystalline silicon 86

[0045] Spray on an aluminum plate with a size of (20*20 cm) by spraying method and form a high temperature resistant wave-absorbing coating with a thickness of 1.3 mm.

[0046] The high temperature resistant electromagnetic wave absorbing coating can be obtained through the above preparation steps. At this time, the performance of the coating is stable at 800° C., and its reflectivity is lower than -5 dB at 10 GHz to 14 GHz, and the peak value reaches -35 dB.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com