Plasticized and toughened wood flour/polypropylene composite and method for preparing same

A composite material, polypropylene technology, applied in the field of plasticized and toughened wood powder/polypropylene composite material, composition and preparation of plasticized and toughened wood powder/polypropylene composite material, which can solve the problem of decreased processing fluidity and impact toughness and other problems, to achieve the effect of reducing processing temperature and color, improving processing fluidity and impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

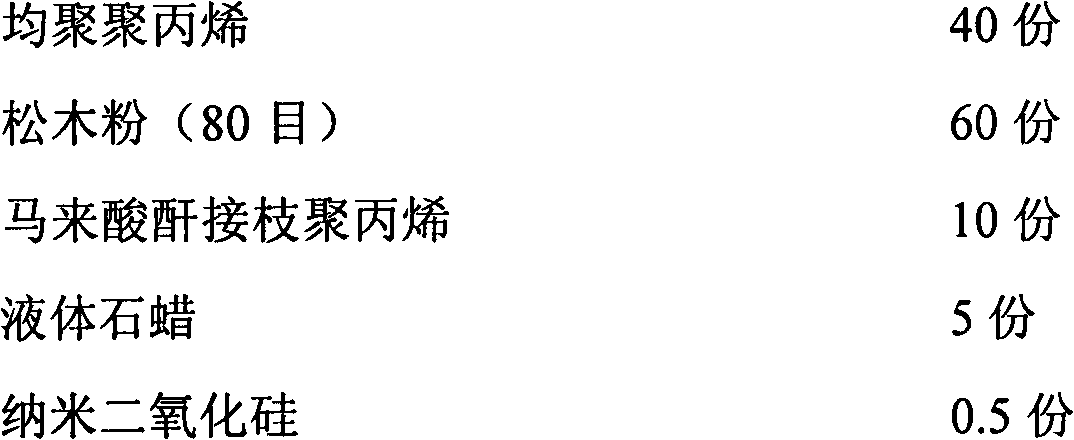

[0018] The material provided by the invention is formulated by weight ratio from the following raw materials:

[0019]

[0020] First, the pine wood powder in the above raw materials was dried in a blast oven at 110°C for 2 hours; then liquid paraffin and nano silicon dioxide were mixed with a high shear emulsifier for 5 minutes to obtain a nano sol; finally Homopolypropylene and maleic anhydride grafted polypropylene are mixed evenly with a low-speed mixer, then fed into the twin-screw extruder from the main feeder, and pine wood powder is added into the twin-screw extruder through the side feeder, and the prepared nano The sol is fed into the twin-screw extruder through a metering pump to obtain a plasticized and toughened wood flour / polypropylene composite material. The barrel temperature of the extruder is 160-200° C., and the screw speed is 100 rpm.

Embodiment 2

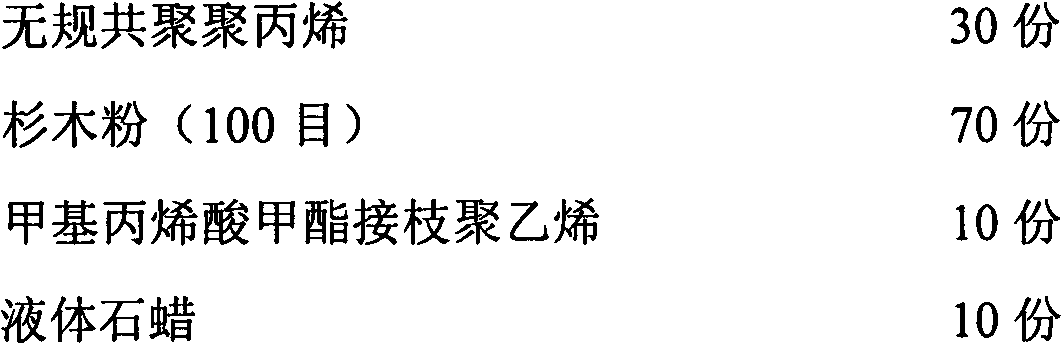

[0022] The material provided by the invention is formulated by weight ratio from the following raw materials:

[0023]

[0024]

[0025] First, dry the fir powder in the above raw materials in a blast oven at 100°C for 3 hours; then mix liquid paraffin and nano-silica with a high-shear emulsifier for 5 minutes to obtain a nano-sol; Random copolymerized polypropylene and methyl methacrylate grafted polyethylene were mixed evenly with a low-speed mixer, and then fed into the twin-screw extruder from the main feeder, and fir powder was added into the twin-screw extruder through the side feeder, and the prepared The obtained nano-sol is fed into a twin-screw extruder through a metering pump to obtain a plasticized and toughened wood flour / polypropylene composite material. The barrel temperature of the extruder is 150-190° C., and the screw speed is 120 rpm.

Embodiment 3

[0027] The material provided by the invention is formulated by weight ratio from the following raw materials:

[0028]

[0029] First, dry the pine wood powder in the above-mentioned raw materials in a blast oven at 110°C for 2 hours; then mix the liquid polyisobutylene and nano-montmorillonite with an ultra-speed mixer for 10 minutes to obtain a nano-sol; finally mix the homopolymer Polypropylene and glycidyl methacrylate grafted polypropylene are mixed evenly with a low-speed mixer and then added to the twin-screw extruder from the main feeder, and the pine wood powder is added to the twin-screw extruder through the side feeder, and the prepared The nano-sol is fed into the twin-screw extruder through a metering pump to obtain a plasticized and toughened wood powder / polypropylene composite material. The barrel temperature of the extruder is 140-190° C., and the screw speed is 140 rpm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com