Complete chloroplast long-time isolated culture method

A technology of in vitro culture and chloroplast, which is applied in the field of plant genetic engineering, can solve the problems such as difficulty in screening chloroplast mutants and transformants, and achieve the effect of convenient observation and detection and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

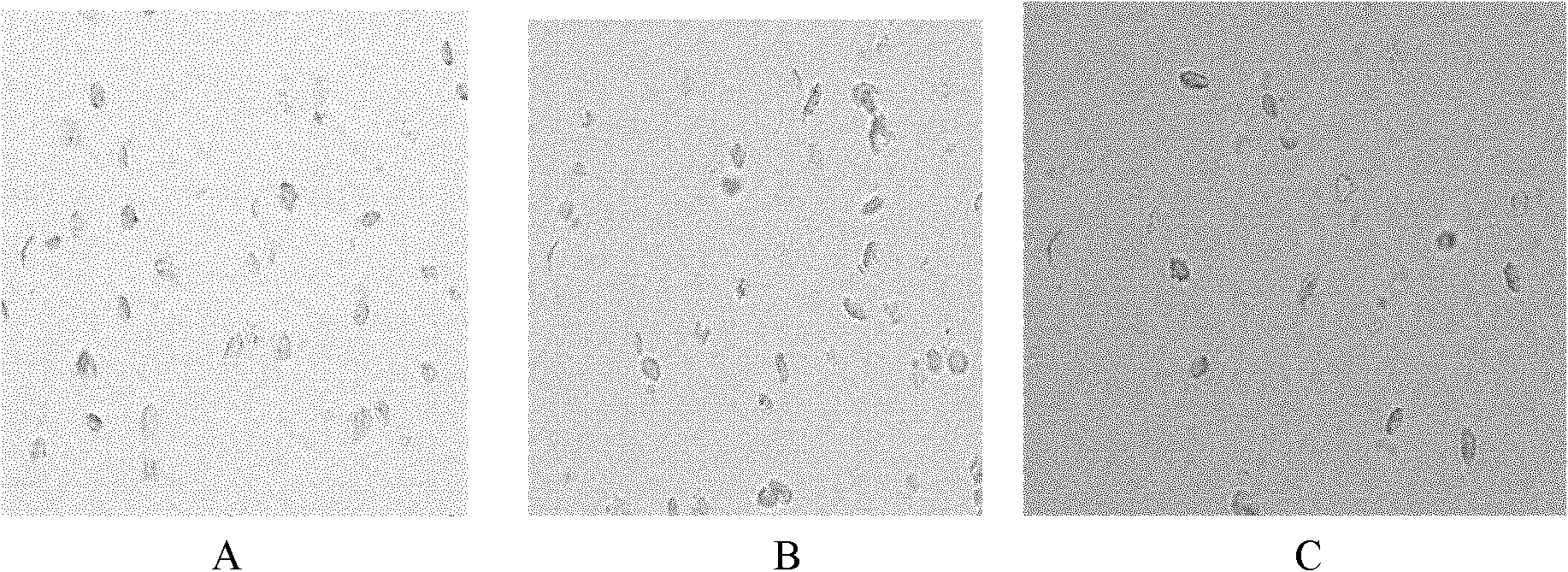

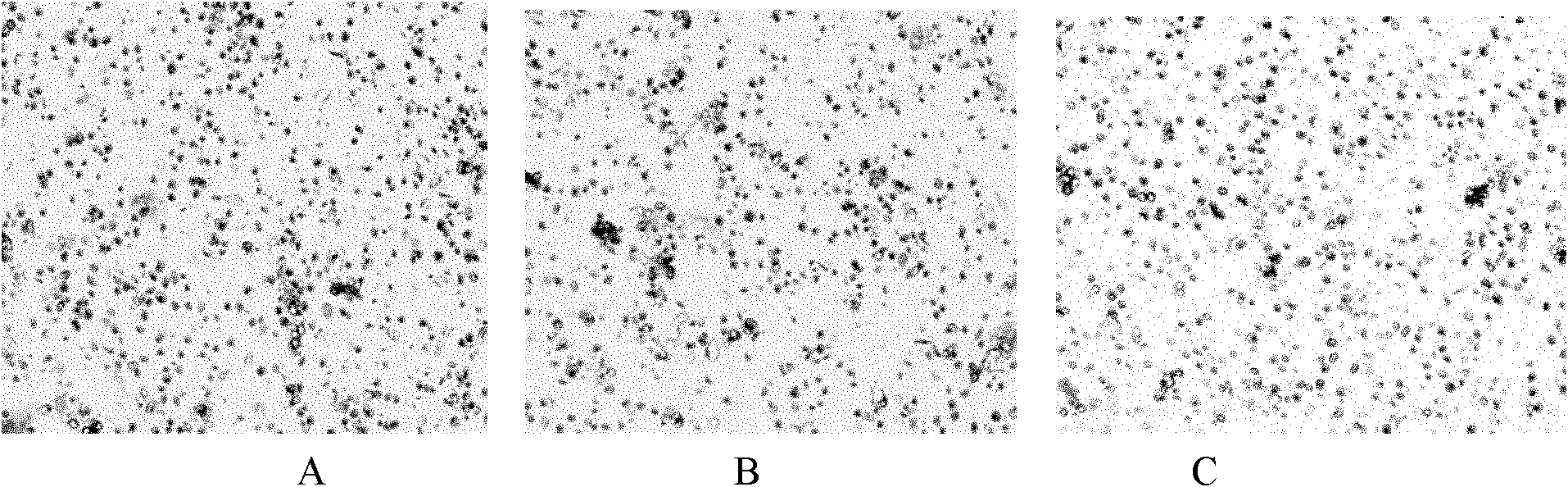

Image

Examples

Embodiment 1

[0033] Embodiment 1: The composition of related reagents for the extraction of complete chloroplasts includes:

[0034]

[0035]

[0036]

[0037] The above reagents were dissolved in deionized water respectively, and stored separately in a refrigerator at 4°C after autoclaving.

Embodiment 2

[0038] Embodiment 2: In vitro culture of complete plant chloroplasts The composition of relevant reagents includes:

[0039]

[0040] The above reagents were dissolved in deionized water, adjusted to pH 6.2, and stored in a refrigerator at 4°C after autoclaving.

Embodiment 3

[0041] Example 3: Operating procedures for extraction of intact chloroplasts and long-term in vitro culture.

[0042] (1) Weigh 8-10 g of cotyledons of fresh plants overnight at 4°C, cut them into pieces, and place them in a mortar pre-cooled on ice.

[0043] (2) Add 40ml of Buffer A into the mortar twice, and add about 1g of quartz sand, after grinding, filter through 6 layers of gauze into a 50ml centrifuge tube (operate on ice).

[0044] (3) Centrifuge at 800 g at 4°C for 6 min, and discard the supernatant.

[0045] (4) Add 25ml of pre-cooled BufferB (add 17.5ul β-mercaptoethanol when used), and suspend chloroplasts.

[0046] (5) Centrifuge at 800 g at 4°C for 8 min, and discard the supernatant.

[0047] (6) Add 12ml BufferC to suspend chloroplasts.

[0048] (7) Centrifuge at 1000 g at 4°C for 8 min, discard the supernatant, and the precipitate is the complete chloroplast obtained by extraction.

[0049] (8) Suspend the complete chloroplast precipitate obtained in step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com