Radio frequency identification (RFID) intelligent clothes hanger entrance and exit control method for intelligent clothing production hanging equipment control system

A technology of smart clothing and control methods, applied in the direction of total factory control, total factory control, electrical program control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make it easier for those skilled in the art to understand and implement the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

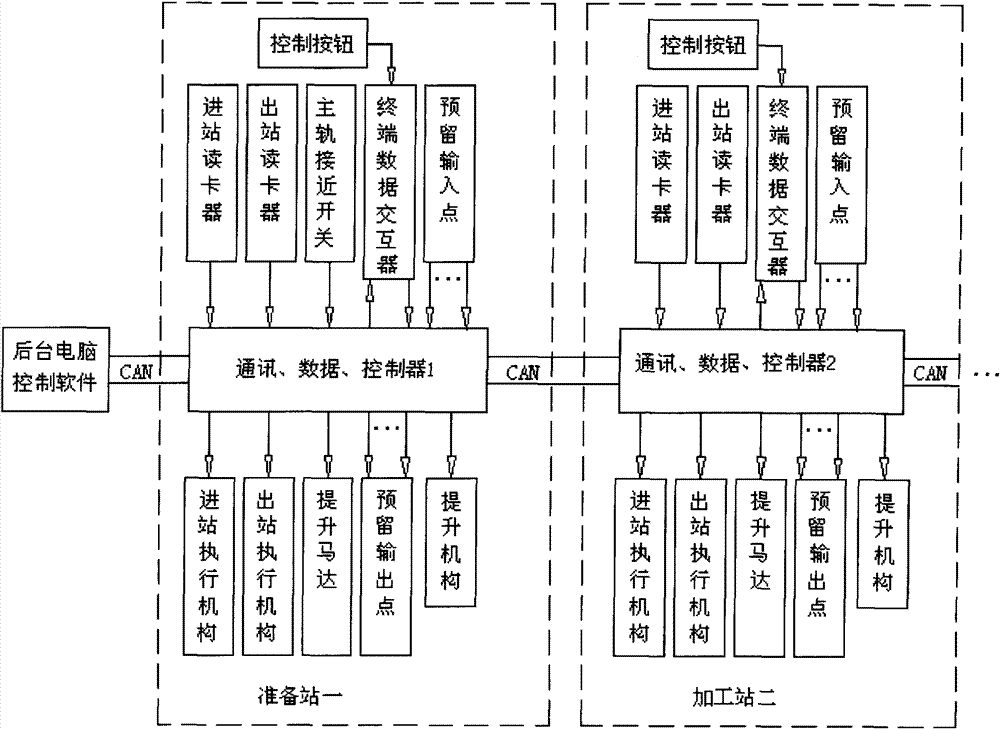

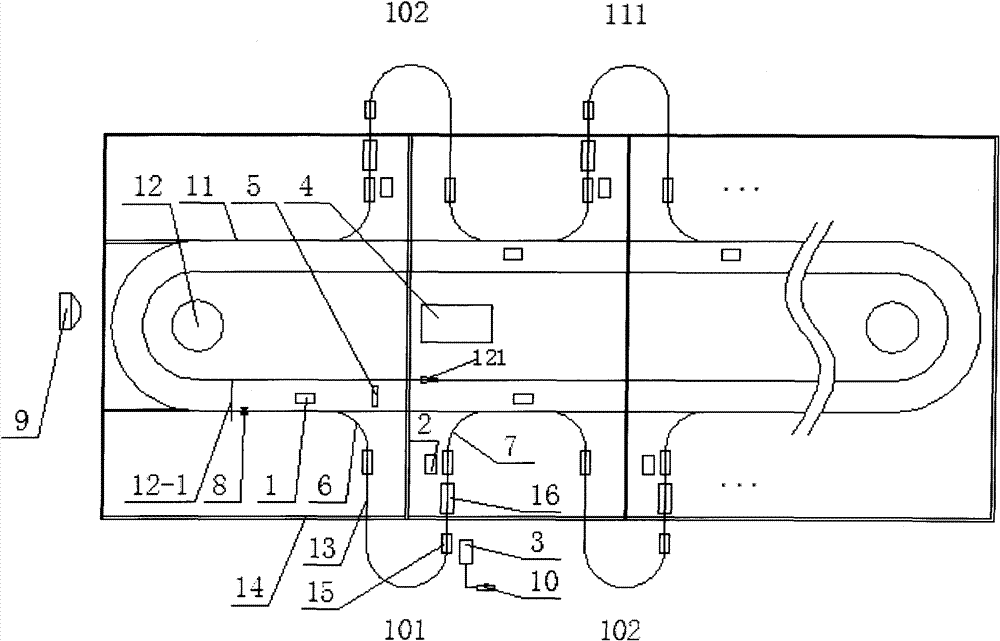

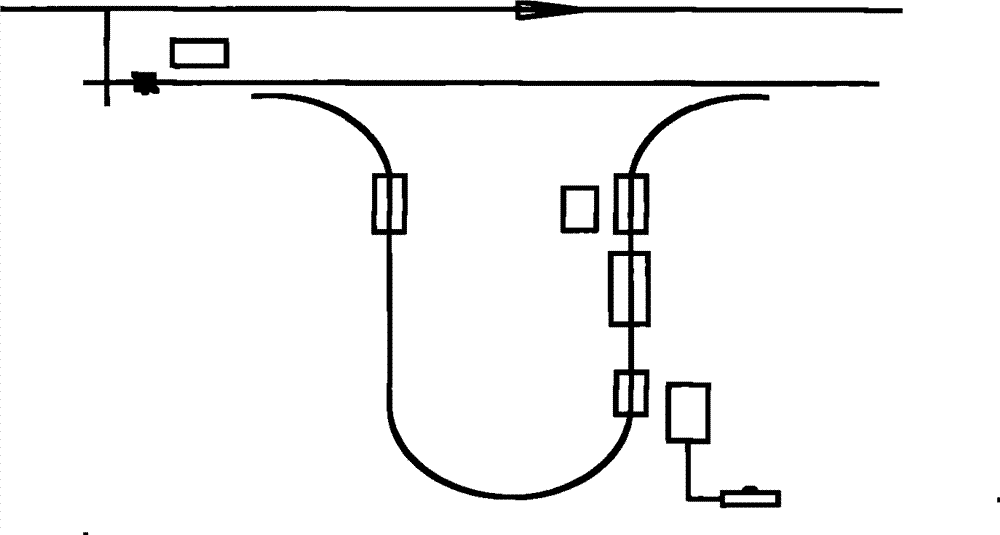

[0046] Such as Figure 1-2 As shown, the present invention is a method for realizing the control system of the hanging equipment for intelligent garment production. The system adopts RFID data acquisition technology and other software and hardware control technologies to realize the intelligent control of the whole process of garment production. The system mainly includes: inbound card reader 1, outbound card reader 2, terminal data interchanger 3, communication data controller 4, push rod proximity switch 5, inbound actuator 6, outbound actuator 7, RFID Smart hanger 8, control center and control software 9, control button 10, main rail 11, driving mechanism 12, push rod 12-1, branch rail 13, equipment frame 14, release mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com