Alkali liquor wet purification technology for aluminum melting furnace smoke

A technology for wet purification and aluminum smelting furnace, applied in the field of flue gas purification, can solve the problems of sticking bags, easily clogged filter bags, corrosion of workshops, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

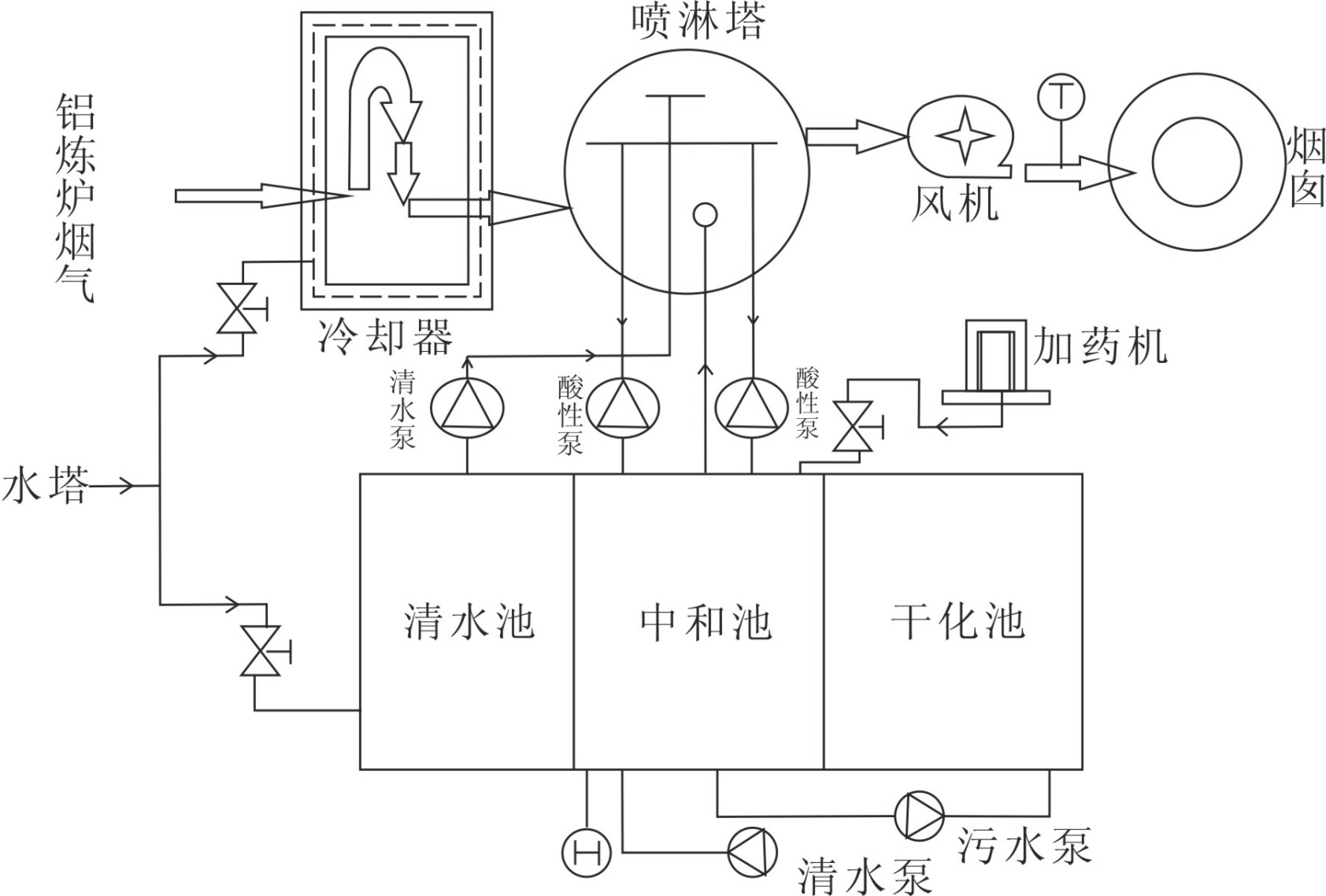

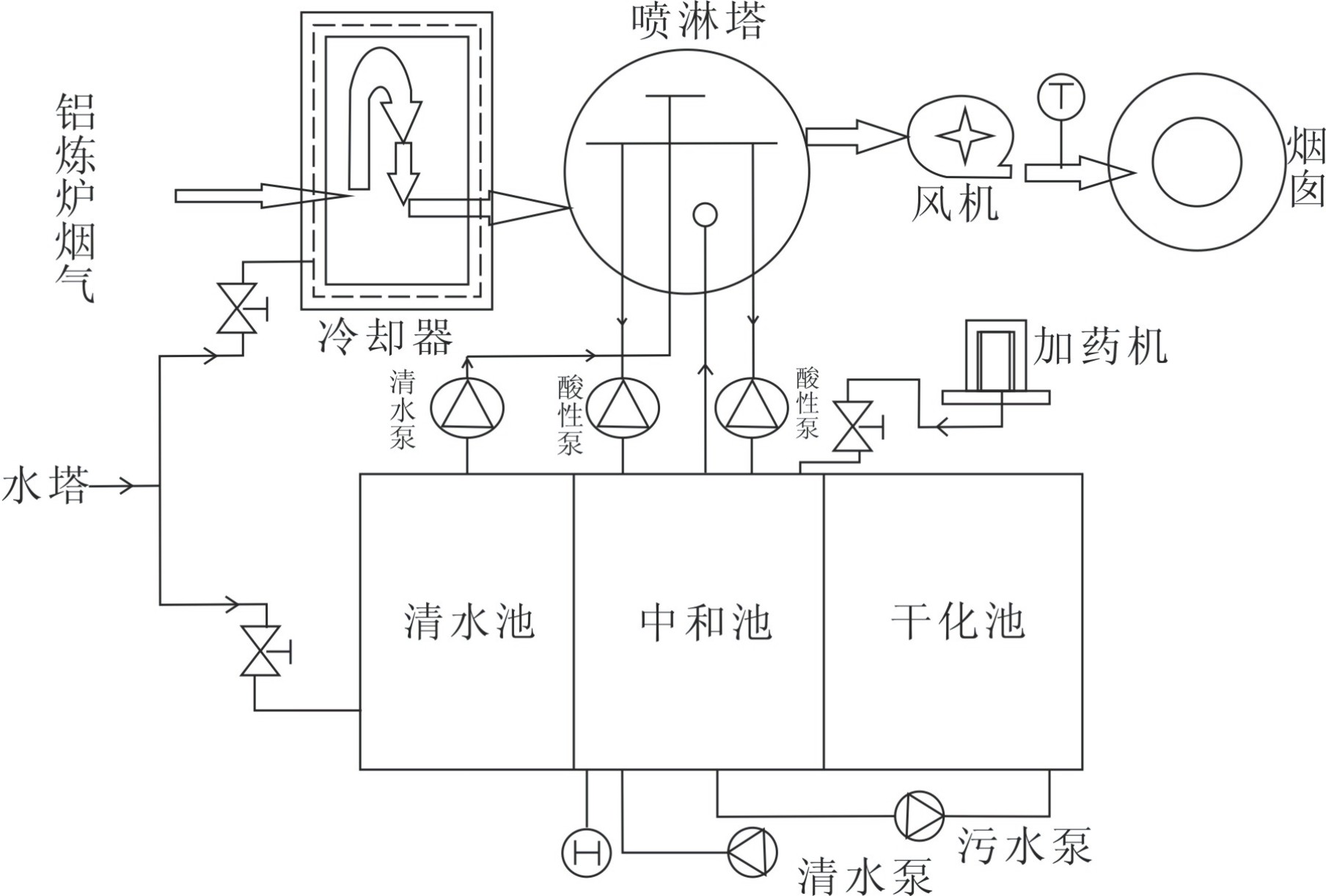

[0014] Example: see figure 1 , an aluminum smelting furnace flue gas lye wet purification technology, including an aluminum smelting furnace flue gas pipe connected by pipes, a cooler, a spray tower, a fan and a chimney, the cooler adopts double-layer pipes, and the inner wall is brushed with Anti-rust paint, the fan is controlled by frequency conversion, and the fan blades are made of acid-resistant materials. The flue gas transported by the flue gas pipe of the aluminum smelting furnace enters the spray tower through the cooler, and the spray tower passes through the negative pressure The running fan is connected to the chimney. The spray tower is a tray-type spray tower with a reinforced concrete structure. The inner surface is made of high-temperature-resistant glass flake resin, and alloy nozzles are installed inside. The tower top cover and internal components are made of stainless steel, the air duct and soft joints are coated with high-temperature anti-corrosion paint,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap