Automobile interior air purification component and device comprising air purification material, as well as use of air purification material and purification component

A technology of air purification materials and air purification devices, which can be applied to vehicle parts, transportation and packaging, air treatment equipment, etc., and can solve problems such as palliatives but not root causes, incompatibility, and pollutants not being removed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0093] The present invention will be further described below in conjunction with specific examples, but they should not be construed as limiting the protection scope of the present invention.

[0094] Reference Example 1: Preparation of nano-titanium dioxide A doped with ferric oxide semiconductor

[0095] At room temperature, 49 grams (0.3mol) of ferric trichloride (Beijing Chemical Materials Co., Ltd.) was dissolved in 1000 ml 5% (weight / volume) of NH 4 OH aqueous solution. Then, 0.6 mol of industrial-grade titanium tetrachloride (Tianjin Chemical Plant) was slowly added dropwise into the aqueous solution in a frozen water bath, and a white precipitate was uniformly produced under uniform stirring. Then add 0.15mol perchloric acid (Beijing Second Chemical Factory) under stirring to dissolve the white precipitate and obtain a transparent liquid. The liquid was evaporated by heating at 95°C for 2 hours to remove excess water and obtain a sol-gel. The resulting sol-gel was f...

Embodiment 3

[0098] Reference Example 3: Preparation of nano-titanium dioxide C doped with zinc oxide semiconductor

[0099] Dissolve 19 g (0.15 mol) of zinc nitrate (Beijing Chemical Materials Co., Ltd.) in 1000 ml of 5% (weight / volume) NH at room temperature 4 OH aqueous solution. Then, 0.6 mol of industrial-grade titanium tetrachloride (Tianjin Chemical Plant) was slowly added dropwise into the aqueous solution in a frozen water bath, and a white precipitate was uniformly produced under uniform stirring. Then, 0.15 mol of nitric acid (Beijing Chemical Raw Material Company) was added under stirring to dissolve the white precipitate and obtain a transparent liquid. The liquid was evaporated by heating at 95°C for 2 hours to remove excess water and obtain a sol-gel. The resulting sol-gel was filtered and washed 4 times with 500 ml of water to bring its pH to 7. The washed sol-gel was dried at 20° C. and 10 mmHg for 5 hours to obtain a white micropowder, which is a metastable titanium di...

Embodiment 1

[0102] According to the mass ratio, take by weighing 47% by weight of pyrolusite powder clay (purchased from Shandong Zibo Zhaoyi Industrial Co., Ltd.), 45% by weight of nano-titanium dioxide A and 8% by weight of activated carbon (purchased from Beijing Kecheng Guanghua New Technology Co., Ltd. Co., Ltd.), under stirring at a speed of 200r / min, add deionized water based on the total weight of 40% by weight of pyrolusite powder clay, nano-titanium dioxide A and activated carbon, mix uniformly, and granulate into small spherical particles. Bake at 100°C for 70 minutes, then raise the temperature to 550°C at a rate of 3°C / min, keep at this temperature for 0.5h, and then sinter to obtain composite particles A1.

[0103] The XRD pattern of the composite particles is shown in Figure 4 , the comparison chart of the intensity of hydroxyl radicals detected by ESR between composite particles A1 and nano-titanium dioxide A raw materials is shown in Figure 5 .

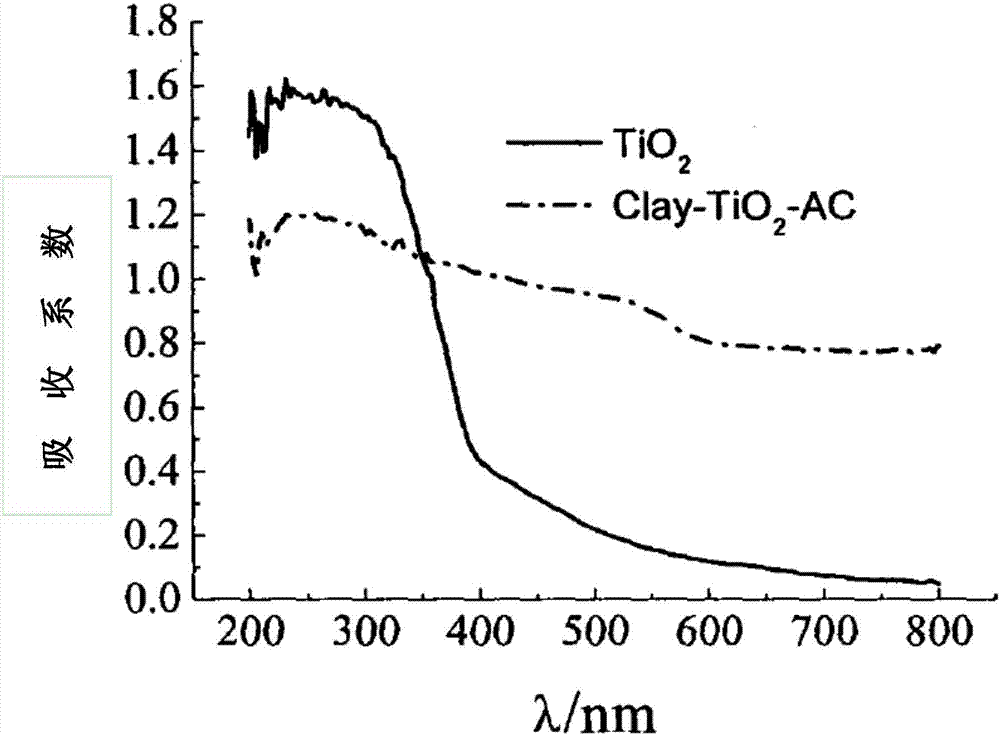

[0104] Depend on Fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap