Palladium/active carbon catalyst and application thereof in synthesizing N,N'-dibenzylethylenediamine

A technology of dibenzylethylenediamine and activated carbon, which can be used in the preparation of organic compounds, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., and can solve the uneven and wide distribution of metal active components , Restricting the activity, selectivity and stability of supported metal catalysts, low metal utilization rate and other issues, to achieve the effect of improving metal utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

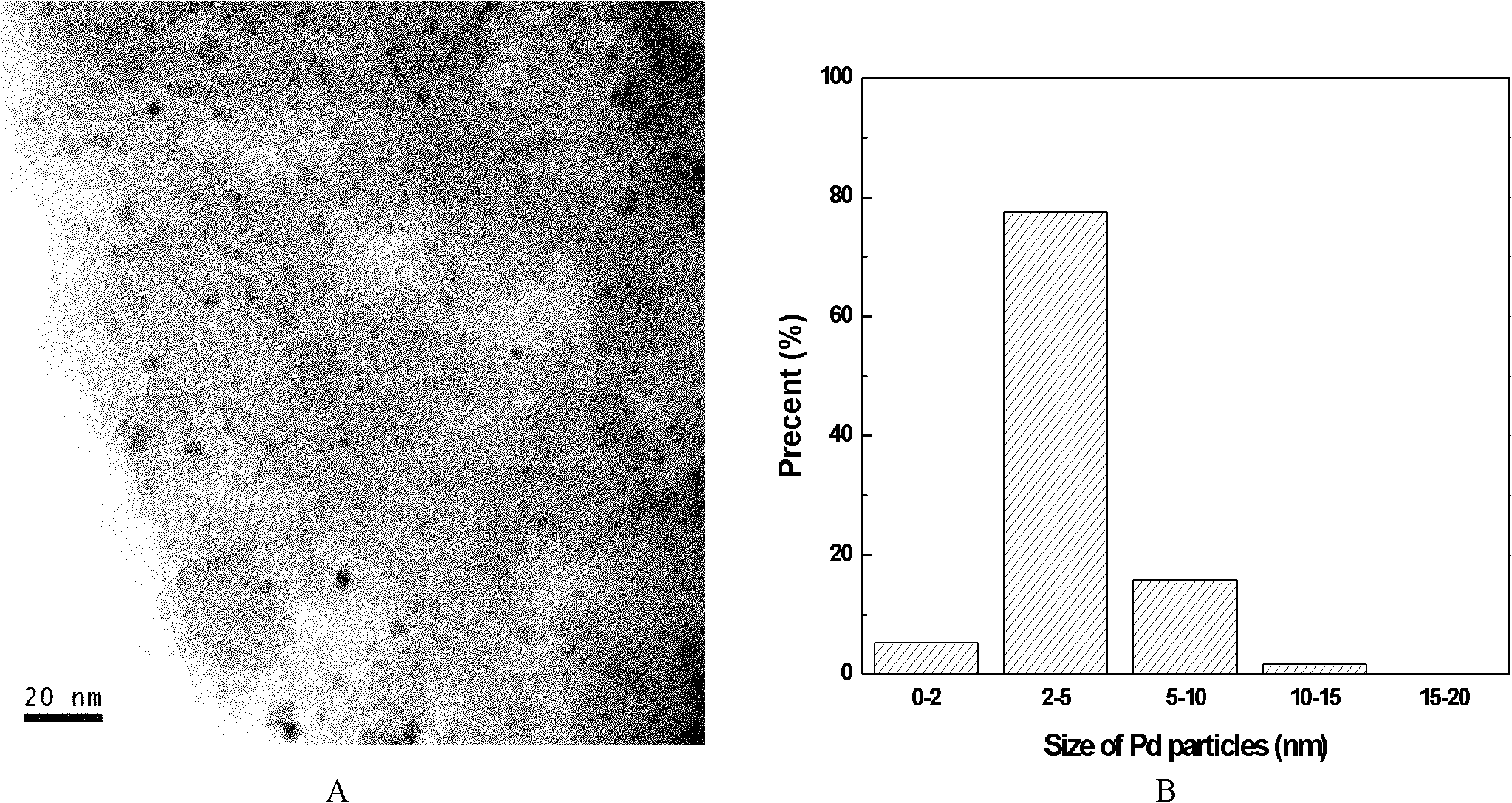

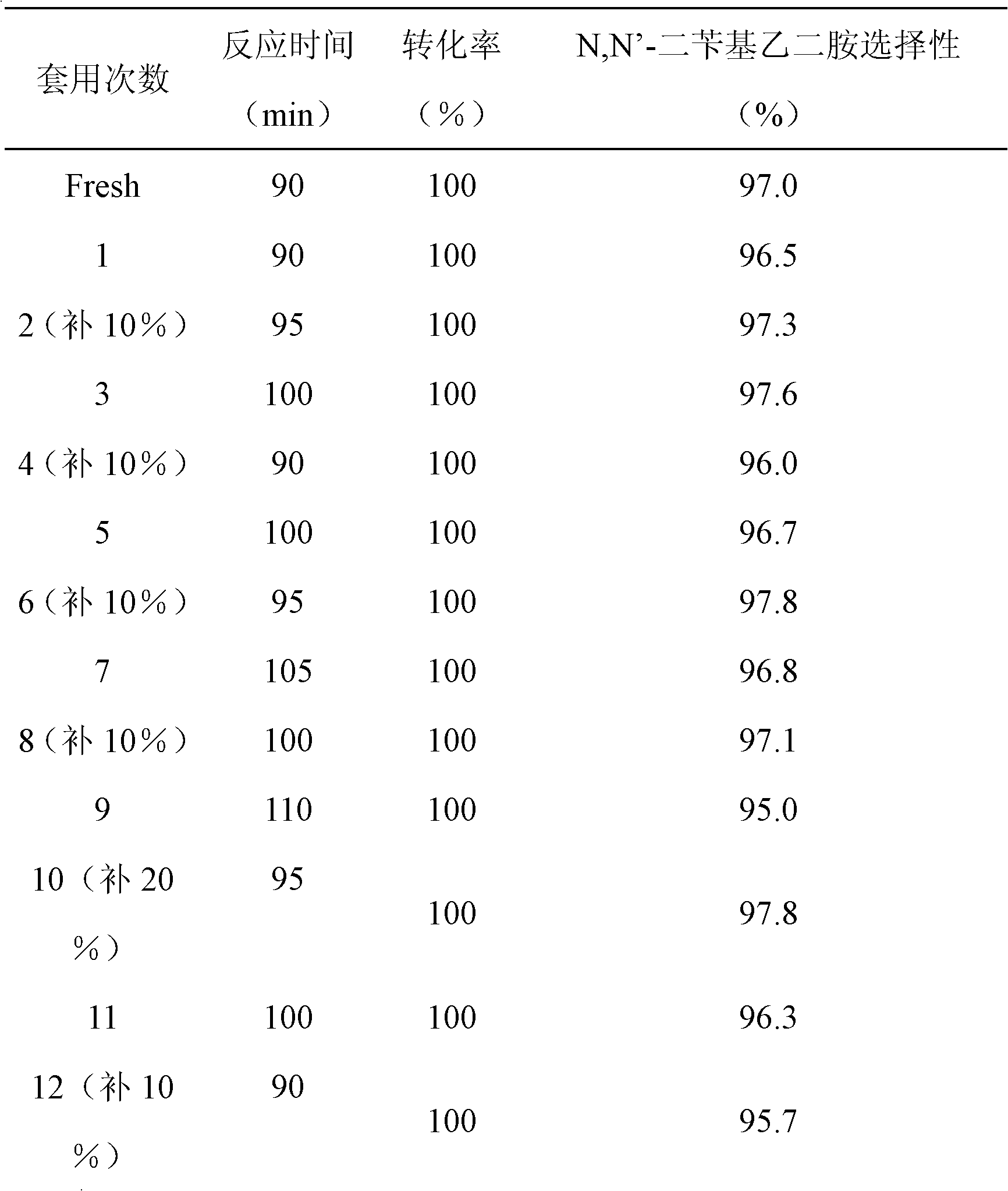

Embodiment 1

[0027] Weigh 10g of activated carbon, the specific surface area of activated carbon is 1600m 2 / g, activated carbon was soaked in 120 milliliters of NaCl solution with a concentration of 0.5mol / l for 2 hours, filtered, and washed with deionized water until no chloride ions were detected. Then the treated activated carbon was formulated into 100ml slurry with a temperature of 60°C, and 10ml of H2PdCl4 solution (Pd content was 0.02g / ml) was slowly added dropwise, stirred for 4h, and the pH value of the solution was adjusted to weakly alkaline with 10% NaOH solution. (pH=7.1), and the temperature was lowered to room temperature, filtered, and washed with deionized water until neutral. The unreduced catalyst was prepared into a 150 ml slurry at 30° C., and then 2 ml of 55% hydrazine hydrate solution was slowly added dropwise, and the stirring was continued for 2 hours. The reduced catalyst was filtered, washed with deionized water until neutral, and finally dried in the air at ...

Embodiment 2

[0029] Weigh 10g of activated carbon, the specific surface area of activated carbon is 1600m 2 / g, activated carbon was immersed in 120 milliliters of NaCl solution with a concentration of 1.0mol / l for 2 hours, filtered, and washed with deionized water until no chloride ions were detected. Then the treated activated carbon was formulated into a 100ml slurry at a temperature of 70°C, and 20ml of H 2 PdCl 4 Solution (Pd content is 0.02g / ml), stirred for 6h, adjusted the pH value of the solution to weak alkaline (pH=8) with 10% NaOH solution, and lowered the temperature to room temperature, filtered, and washed with deionized water until neutral . The unreduced catalyst was prepared into a 150ml slurry at 30°C, and then 2ml of 55% hydrazine hydrate solution was slowly added dropwise, and the stirring was continued for 2 hours. The reduced catalyst was filtered, washed with deionized water until neutral, and finally dried in the air at room temperature, and the wet sample was ...

Embodiment 3

[0031] Weigh 10g of activated carbon, the specific surface area of activated carbon is 1600m 2 / g, activated carbon was soaked in 120 ml of NaCl solution with a concentration of 1.5 mol / l for 2 hours, filtered, and washed with deionized water until no chloride ions were detected. Then the treated activated carbon was formulated into a 100ml slurry at a temperature of 80°C, and 20ml of H 2 PdCl 4 Solution (Pd content is 0.02g / ml), stirred for 6h, adjusted the pH value of the solution to weak alkaline (pH=8) with 10% NaOH solution, and lowered the temperature to room temperature, filtered, and washed with deionized water until neutral . The unreduced catalyst was prepared into a 150ml slurry at 30°C, and then 2ml of 55% hydrazine hydrate solution was slowly added dropwise, and the stirring was continued for 2 hours. The reduced catalyst was filtered, washed with deionized water until neutral, and finally dried in the air at room temperature, and the wet sample was taken and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com