Pipeline cleaner ball receiving device with high gradient magnetic separator and powder separation method

A high-gradient magnetic separation and pigging technology, applied in high-gradient magnetic separators, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of large fluctuation range of gas volume in gas pipelines, damage to instruments, and high pressure. , to avoid potential risk factors, reduce the pressure drop of natural gas, and improve the effect of purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

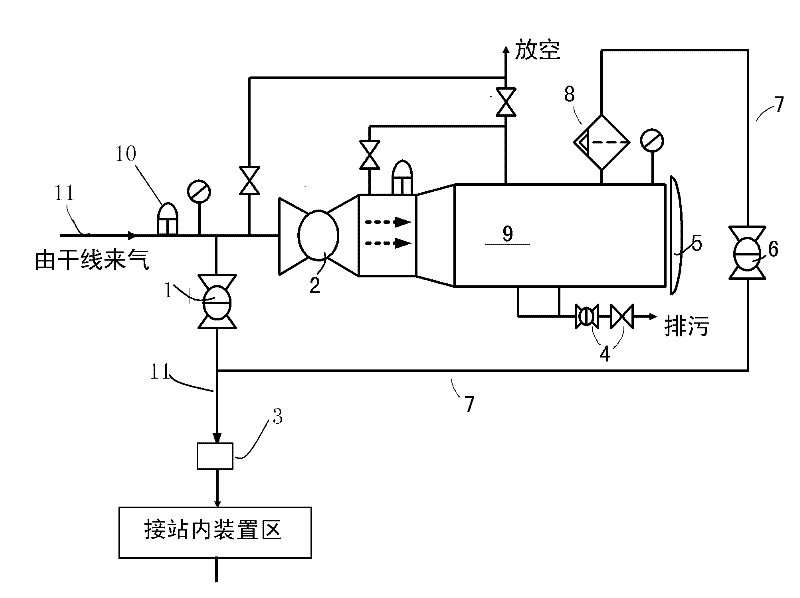

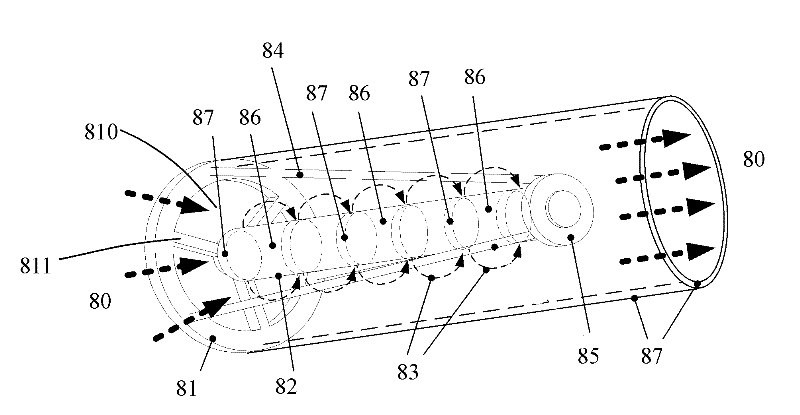

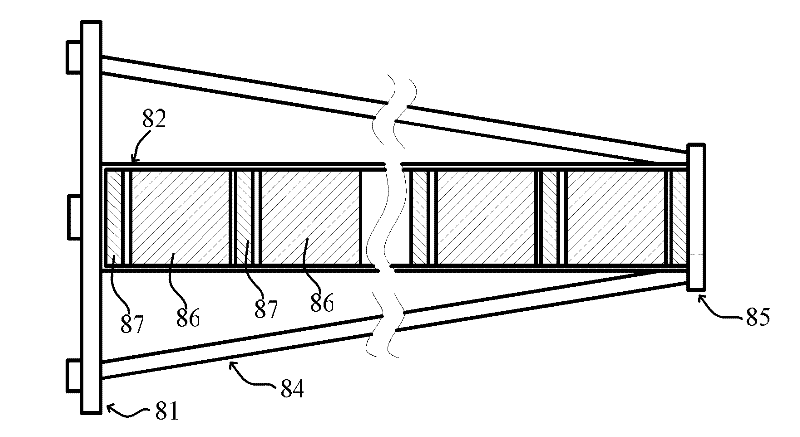

[0041] The invention proposes a pig collecting device with a high-gradient magnetic separator. The device has a pig collecting cylinder and a high-gradient magnetic separator arranged in sequence on the main gas pipeline, wherein the ball collecting cylinder It is connected to the main gas pipeline at the front end of the production valve, one end of a drainage tube is connected to the ball receiving cylinder, and the other end is connected to the rear end of the production valve; at least one high-gradient magnetic separator is arranged on the drainage pipe inside the tube. The invention installs the high-elevator magnetic separator in the drainage tube of the ball collection tube on the main gas transmission pipeline to separate the solid impurities in the transported gas during the pigging operation, and uses the high-gradient magnetic separation technology to greatly reduce the downstream after pigging operation. The powder concentration in the main gas pipeline, especiall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com