Method for preparing coated nano zero valent iron by rheological phase reaction method, and prepared product thereof

A nano-zero-valent iron and rheological phase technology, applied in the direction of improving process efficiency, can solve problems such as difficulties in transportation, storage and use, difficulty in performance, and harsh preparation conditions, so as to reduce the requirements for the preparation environment and equipment, and improve the production efficiency. Environmental affinity and effect of improving dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

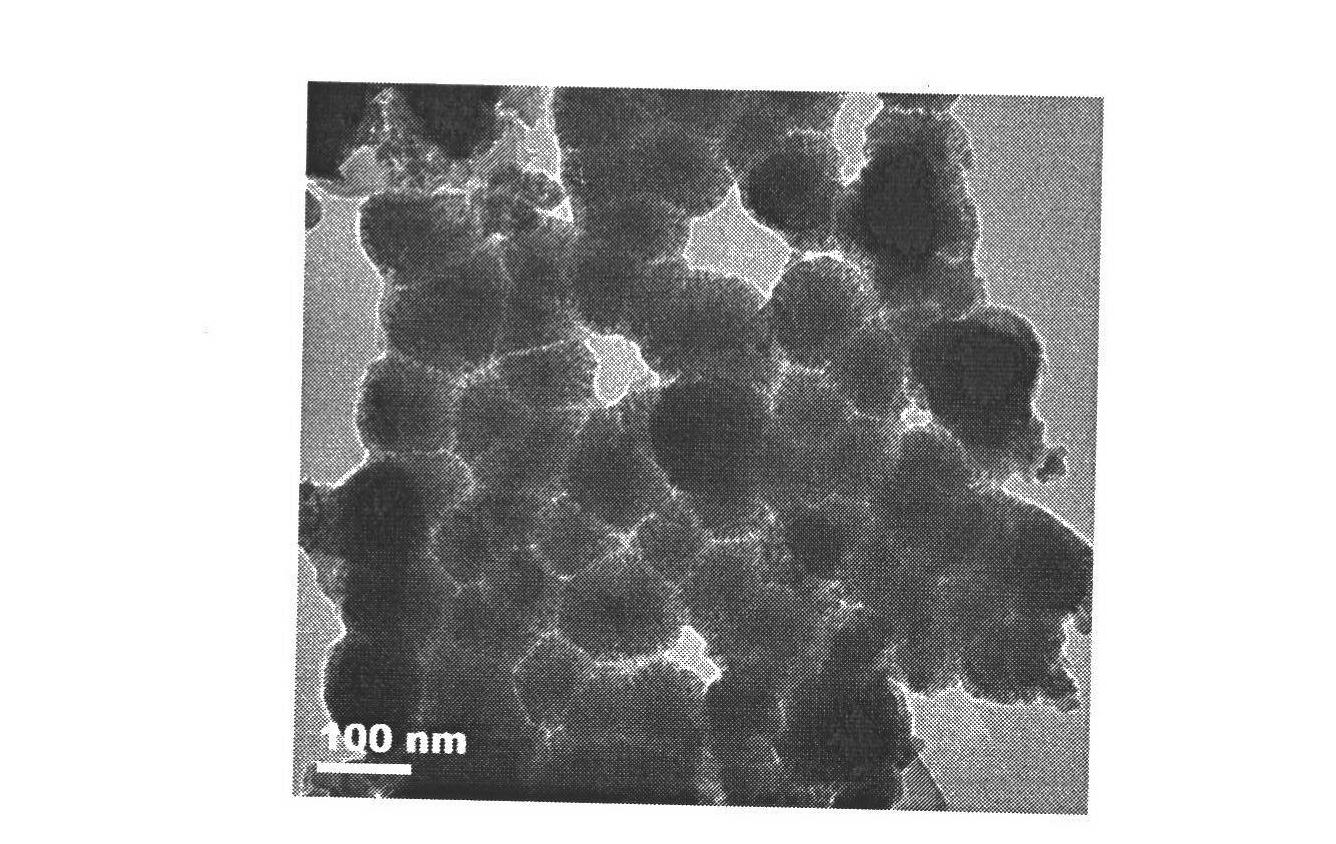

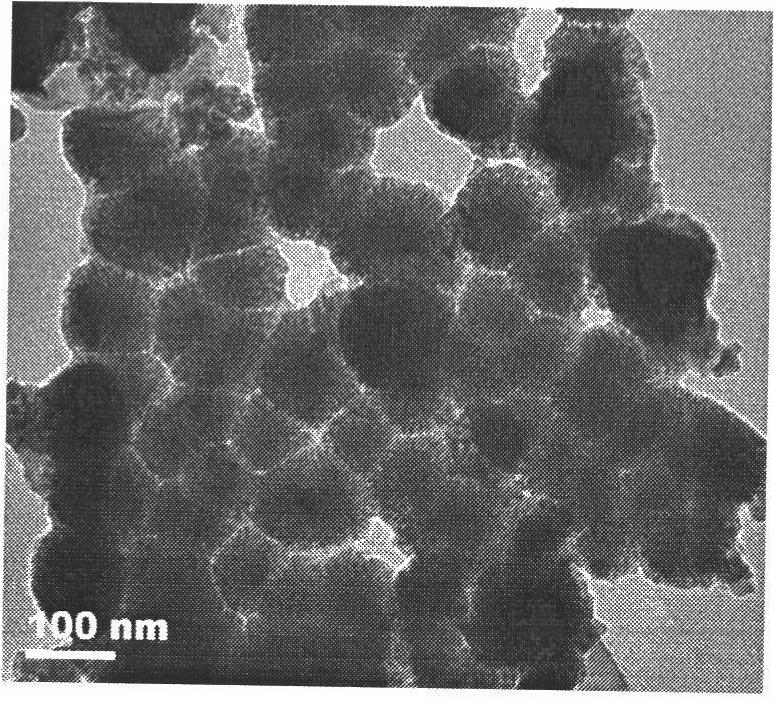

Image

Examples

Embodiment

[0018] Step 1: Dissolve 6g of CMC in 100mL of deionized water, and stir with a magnetic stirrer for 1 hour under the condition of slight heating at 40°C to prepare a liquid medium for insulation;

[0019] Second step: accurately weigh 2 mol of chemically pure ferrous sulfate and 4 mol of potassium hydrogen borate, mix them in a mortar for 10 minutes, and prepare a solid mixture for subsequent use;

[0020] Step 3: Weigh 50g of the solid mixture into a 200ml beaker, add 100ml of CMC liquid medium for mixing, and stir for 30 minutes to prepare a rheological state;

[0021] The fourth step: carry out rheological phase reaction for 2 hours under vacuum and normal temperature stirring to obtain a solid-liquid mixture of zero-valent iron and boric acid;

[0022] Step 5: Wash the solid-liquid mixture of zero-valent iron and boric acid with 100mL of absolute ethanol for 3 times. When washing, use a magnet to attract the solid matter at the bottom so that the liquid can be poured out. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com