Method for preparing carbon quantum dots

A carbon quantum dot and quality technology, applied in the field of quantum dot preparation, can solve the problems of difficulty in obtaining raw materials, low fluorescence quantum yield of carbon quantum dots, and inability to large-scale production, and achieves the effect of simple process operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

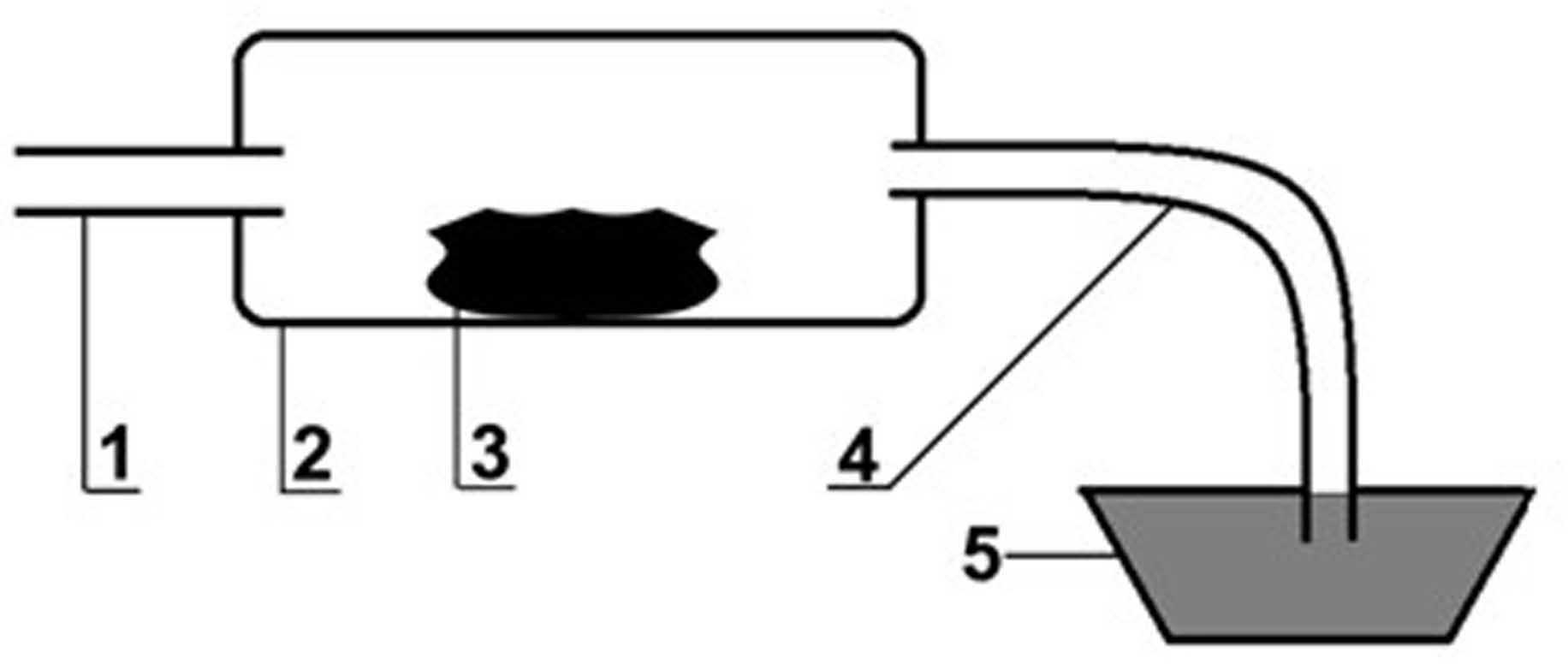

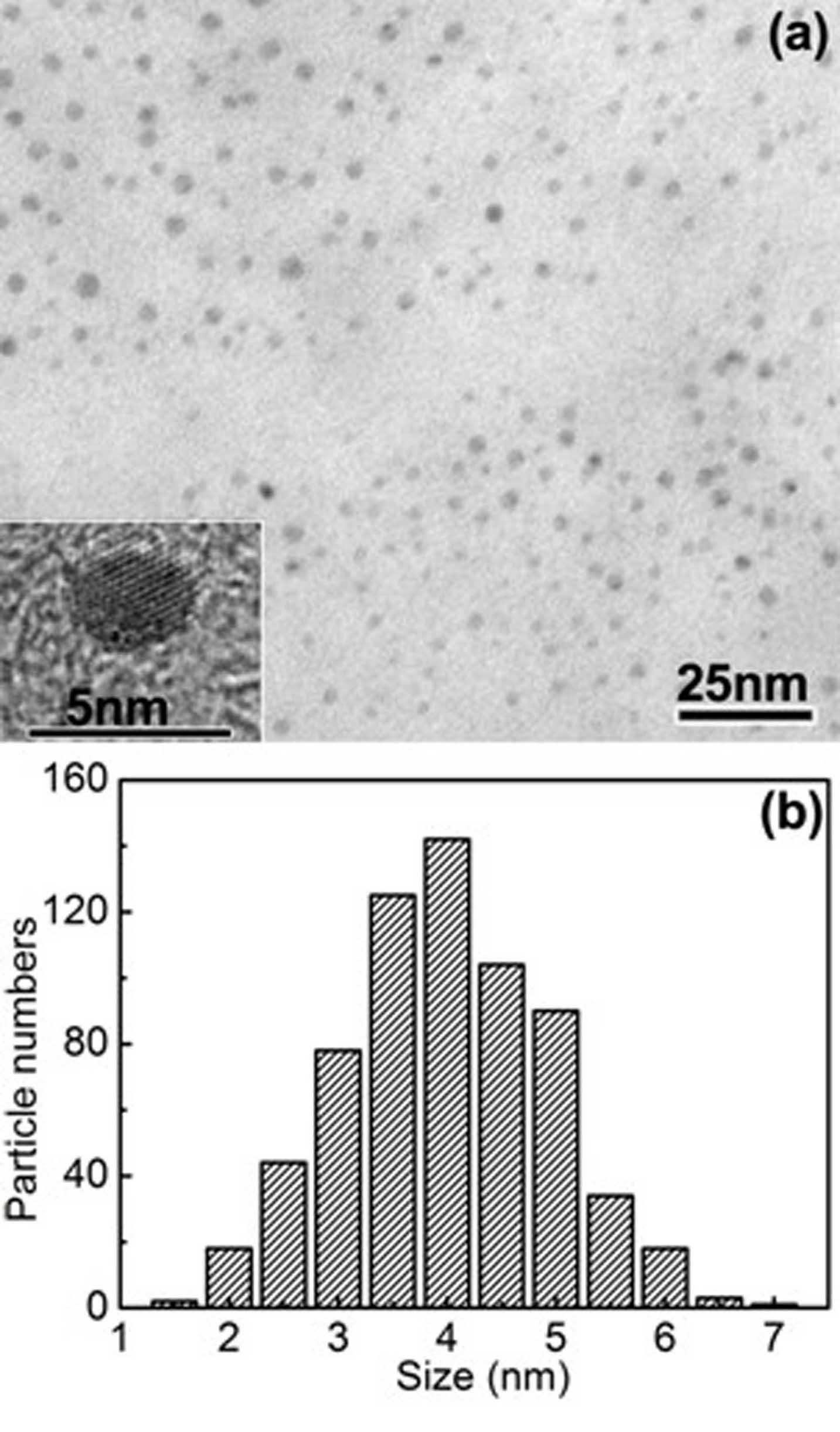

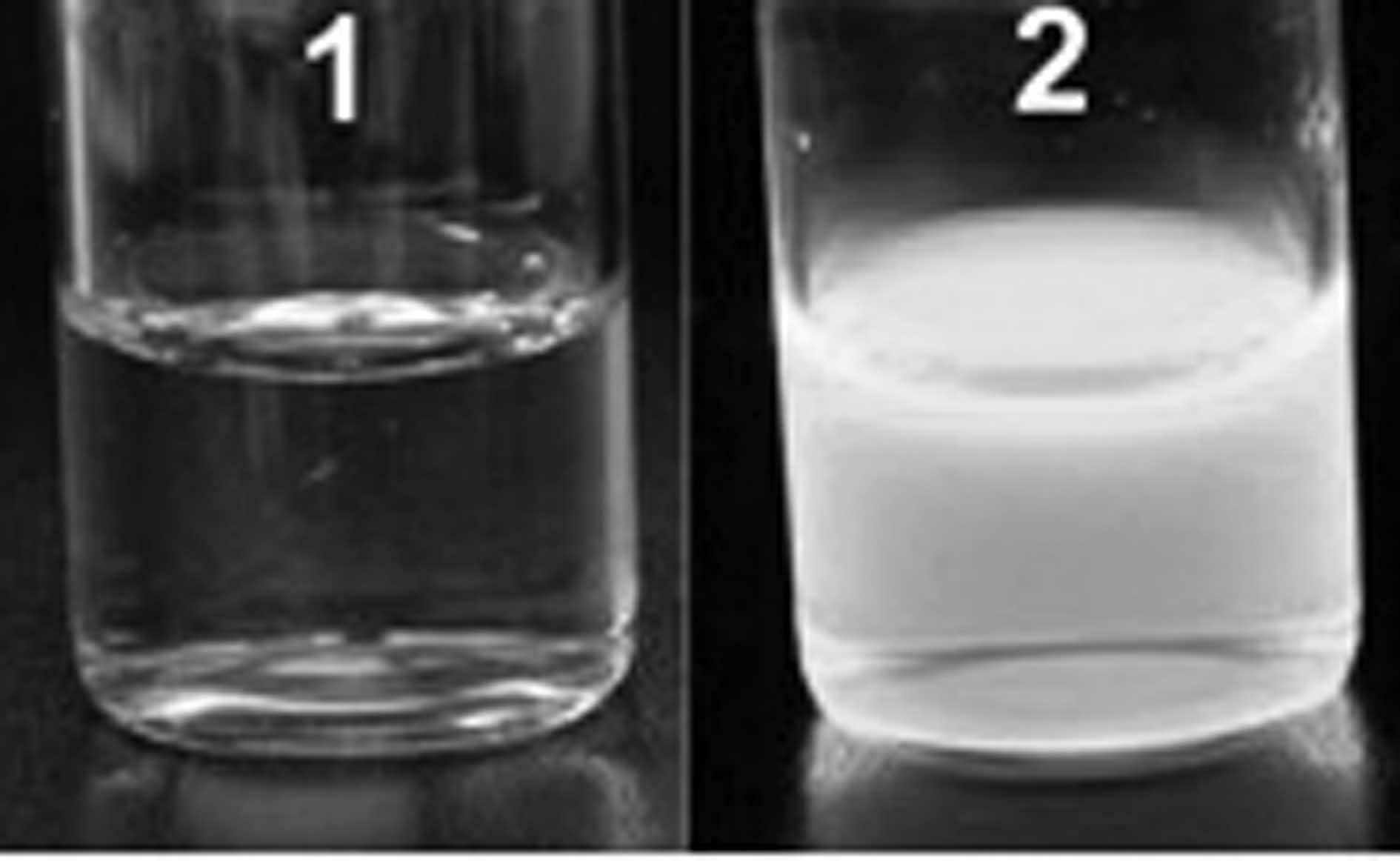

Embodiment 1

[0021] Embodiment 1: a kind of preparation method of carbon quantum dot comprises the following steps: m =500 g dry poplar sawdust was heated in a tube-type electric heating furnace, the reaction temperature was 350 °C, and the volume of air introduced into the tube-type electric heating furnace per minute was V =250 L of air, making V : m =0.5, the flue gas generated by the reaction is introduced into the water tank through the flue gas outlet pipe to obtain soot; the soot obtained above is added to 2.5 mol / L nitric acid solution for reflux acid cooking, and the reaction time is 10 hours. After the reaction, the pH value of the solution was adjusted to 6~8, and then the solid product was obtained after removing water; the solid product obtained after removing the water was mixed with polyethylene glycol with a molecular weight of 200 in deionized water at a mass ratio of 3:2 and placed in a constant temperature box, the reaction temperature was maintained at 105 ° C, the re...

Embodiment 2

[0022] Embodiment 2: a kind of preparation method of carbon quantum dot comprises the following steps: m =600 g of dry pagoda tree sawdust was heated in a tubular electric heating furnace, the reaction temperature was 450 °C, and the volume of the air introduced into the tubular electric heating furnace per minute was V =3600 L of air, making V : m =6, the flue gas generated by the reaction is introduced into the water tank through the flue gas outlet pipe to obtain soot; the soot obtained above is added to 3.6 mol / L nitric acid solution for reflux acid cooking, the reaction time is 12 hours, and the After the reaction, the pH value of the solution was adjusted to 6~8, and then the solid product was obtained after removing water; the solid product obtained after removing the water was mixed with polyethylene glycol with a molecular weight of 3000 in deionized water at a mass ratio of 3:1 and placed in a constant temperature box, the reaction temperature was maintained at 135...

Embodiment 3

[0023] Embodiment 3: a kind of preparation method of carbon quantum dot comprises the following steps: m = 650 g of dried cotton stalks were put into a tubular electric heating furnace for heating, and the reaction temperature was 400 °C. V =1950 L of air, making V : m =3, the flue gas generated by the reaction is introduced into the water tank through the flue gas outlet pipe to obtain soot; the soot obtained above is added to 3 mol / L nitric acid solution for reflux acid cooking, and the reaction time is 11 hours. After the reaction, the pH value of the solution was adjusted to 6~8, and then the solid product was obtained after removing water; the solid product obtained after removing the water was mixed with polyethylene glycol with a molecular weight of 1500 in deionized water at a mass ratio of 3:1.5 and placed in a constant temperature box, the reaction temperature was maintained at 120 ° C, the reaction time was 60 hours, and then centrifuged at a centrifugal rate of 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com