Process method for combining physical-chemical treatment and biochemical treatment for reinjection water with oil-field produced water

A technology of biochemical treatment and process method, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. Disinfection and other issues to achieve the effect of saving costs and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

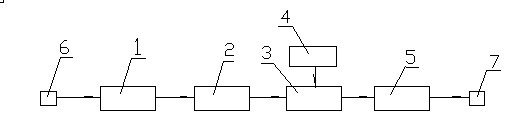

[0022] The following takes oilfield produced water as an example, combined with the attached figure 1 , attached figure 2 To be specific:

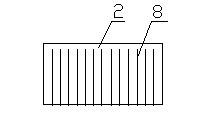

[0023] The oil field produced water 6 first passes through the oil removal pool unit 1, and the floatable oily substances and most of the particles with a density higher than water are removed in this unit. After that, it enters the electrocoagulation unit 2 for treatment. Through physical and chemical effects, aluminum hydroxide is formed on the plate 8 made of metal aluminum under an applied voltage, and micro-bubbles are generated, which destabilizes the colloids in the wastewater and collides with each other to form flocculation. Driven by the micro-bubbles, the flocs float to the surface of the water body, and then remove most of the oil and most of the suspended solids. The oil content in the effluent is lower than 5mg / l, and the suspended solids (SS) are lower than 40mg / l; The material of the body plate is metal aluminum, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com