Method and system for biologically treating restaurant and kitchen garbage at high speed

A technology for kitchen waste and biological treatment, applied in the fields of biochemical equipment and methods, anaerobic digestion treatment, chemical instruments and methods, etc., can solve the problem of not completely blocking the waste oil, garbage pig loopholes, low, and can only deal with restaurants , canteen leftovers, inhibiting the promotion and application of waste biological treatment technology, etc., to achieve the effect of improving biological digestion speed, low waste treatment cost, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: The high-speed biological treatment method of kitchen waste of the present invention, first pre-treats kitchen waste or high-concentration organic sewage, removes grease and performs preliminary hydrolysis and acidification treatment, adjusts pH, and then performs anaerobic digestion treatment, the present invention and The difference in the prior art is that: the anaerobic digestion treatment process uses at least three stages of anaerobic reactors, and the anaerobic digestion process uses an ultra-high temperature anaerobic digestion process. The maximum anaerobic reaction temperature is close to 70 degrees, much higher than the current 55 degrees.

[0024] At present, single-stage or two-stage anaerobic digestion processes are commonly used at home and abroad. Practice has proved that using two-stage anaerobic digestion process, that is, creating two different biological nutrient environments (such as temperature, pH, etc.) through two reactors, can imp...

Embodiment 2

[0026]Embodiment 2: The high-speed biological treatment method for kitchen waste in this embodiment, the anaerobic digestion process includes ultra-high temperature hydrolysis acidification and high-temperature methane production reaction process, the temperature of the ultra-high temperature hydrolysis acidification reactor is controlled at 65-68 degrees, and the pH value is set for pH 5.5-6; the temperature of the high-temperature methanogenic reactor is controlled at 53-56 degrees, and the pH value is set at 6.8-7.5.

[0027] The traditional anaerobic digestion process of organic matter is theoretically considered: the digestion temperature of natural anaerobic digestion process is 10-26 degrees, and the digestion cycle is 40-60 days; the digestion temperature of medium-temperature anaerobic digestion process is 35 degrees, and the digestion cycle is 20 days; The digestion temperature is 55 degrees, and the digestion cycle is 15 days. At present, the anaerobic digestion pro...

Embodiment 3

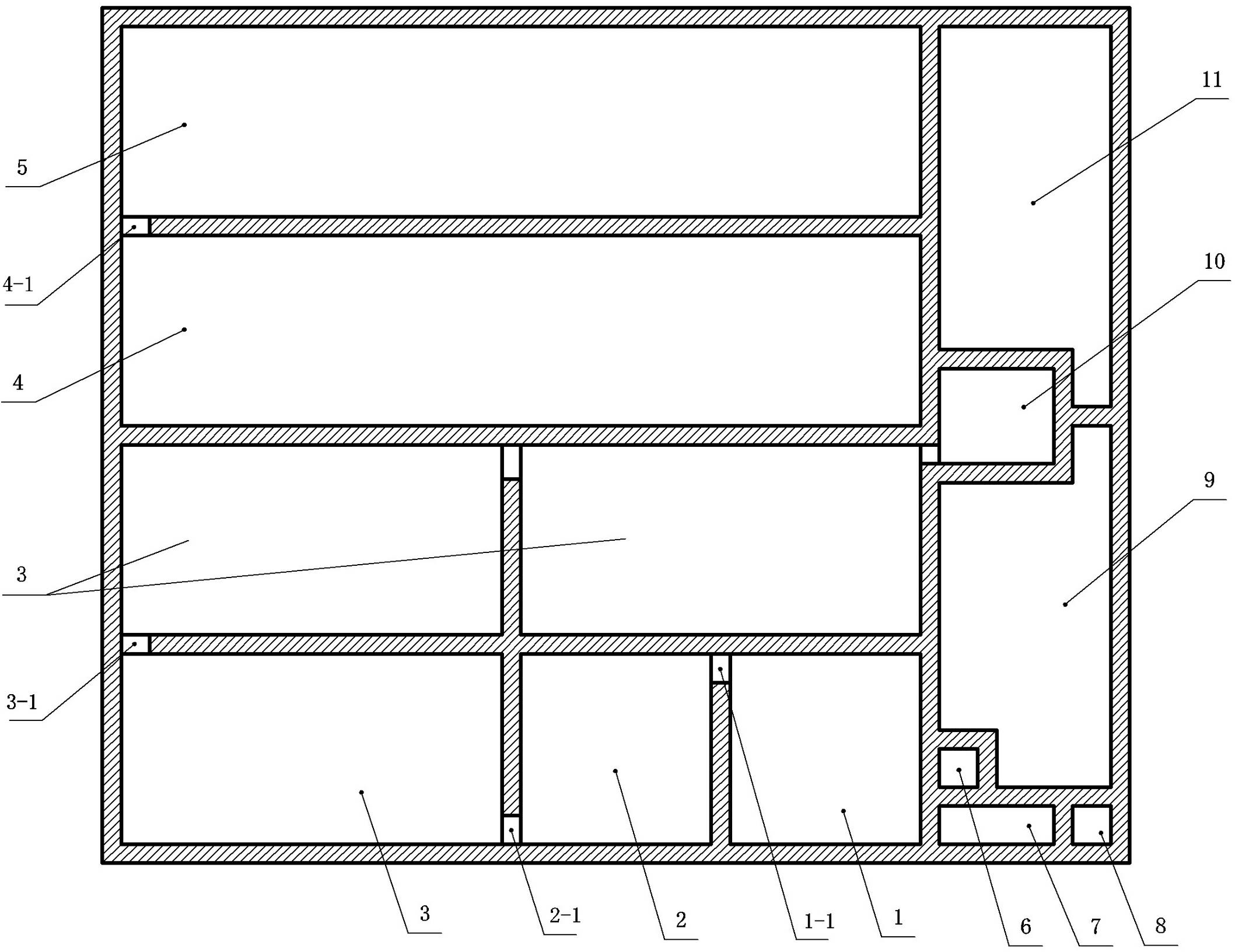

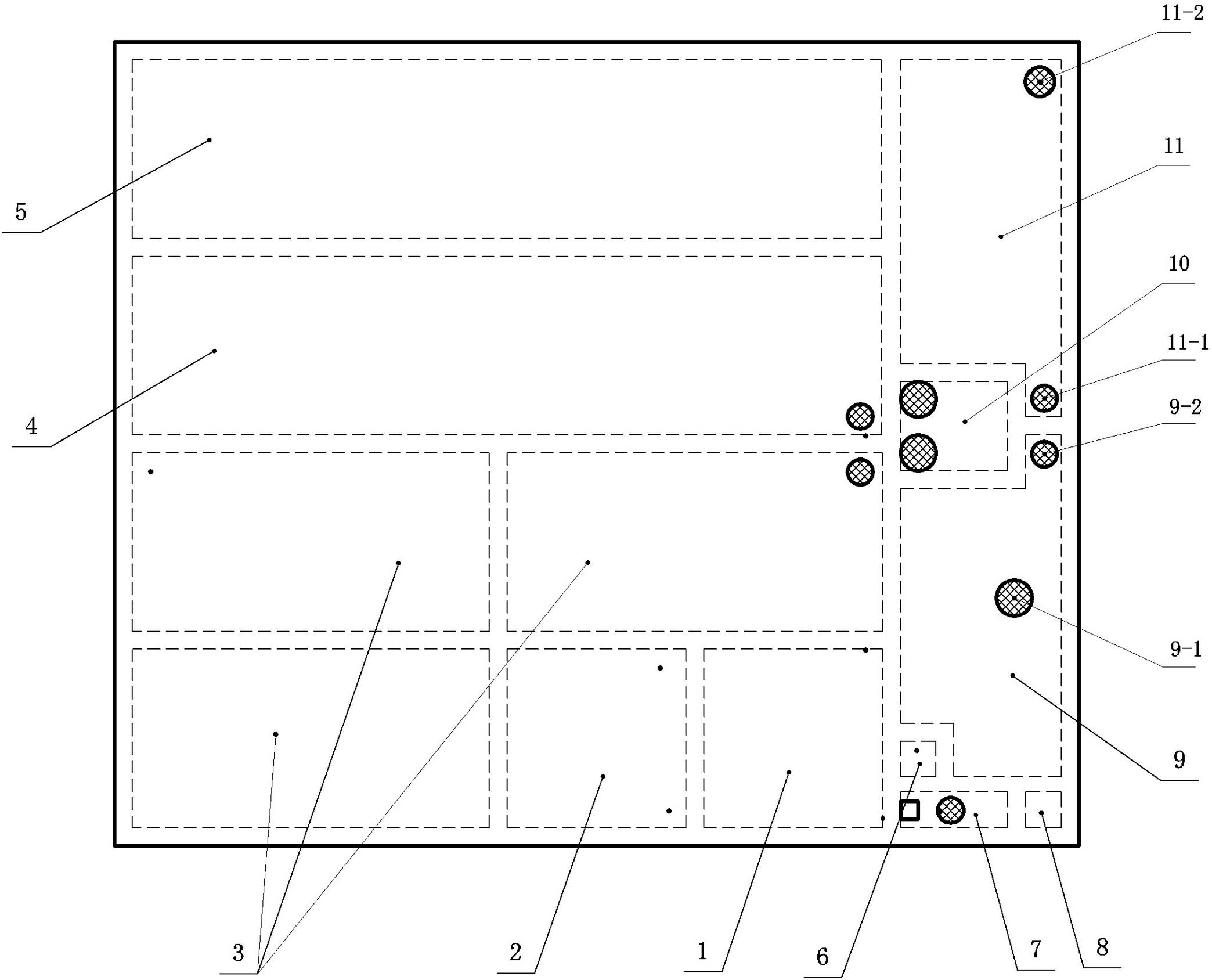

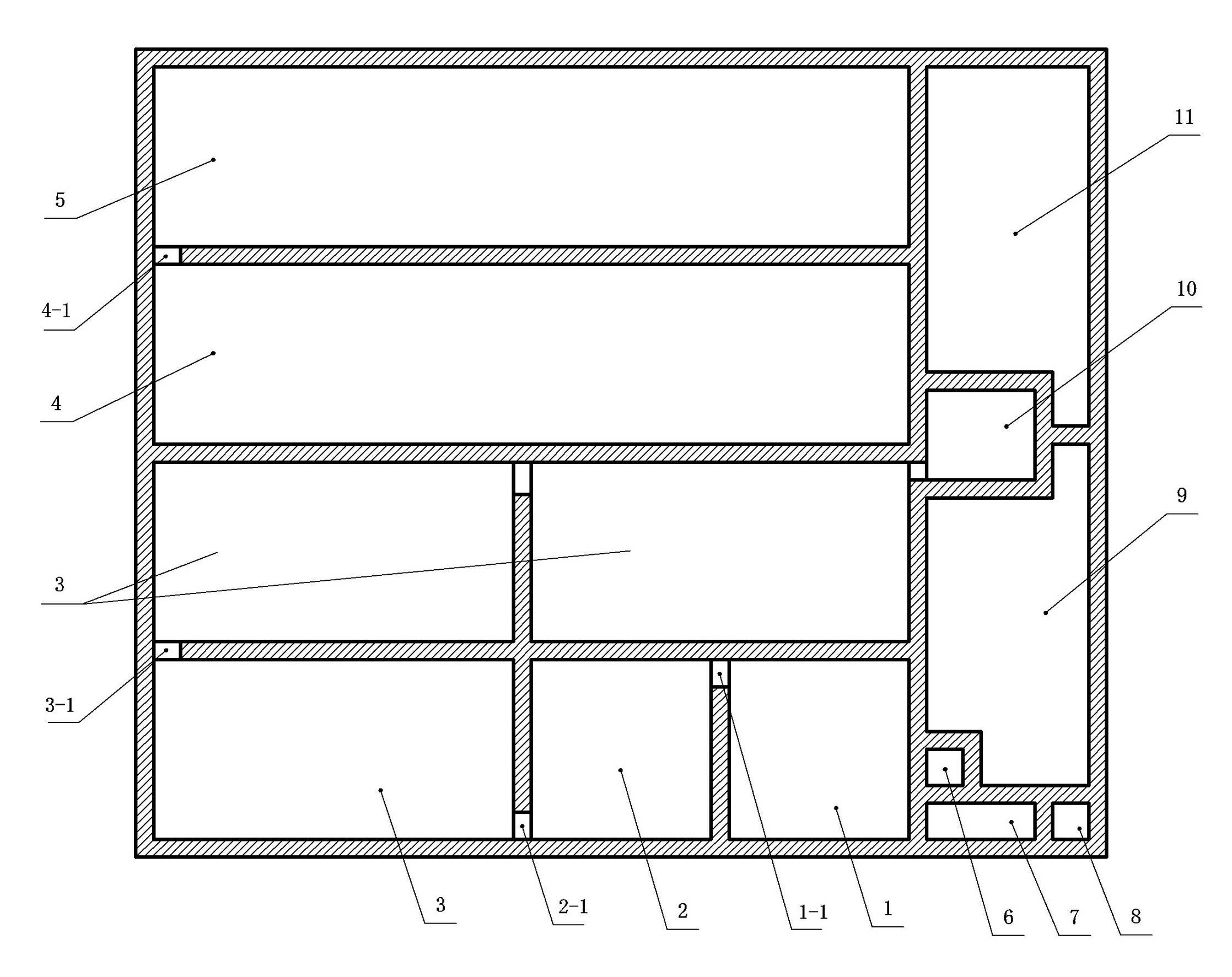

[0030] Embodiment 3: The high-speed biological treatment method of kitchen waste in this embodiment is different from Embodiment 2 in that: the ultra-high temperature hydrolysis and acidification reaction process is carried out in a two-stage reactor, and the temperature of the first stage is controlled at 65-68 degrees. The pH value is set at 5.5-6, the second stage is a transition reactor, the temperature is controlled at 60-63 degrees, and the pH value is set at 6-6.5; the high-temperature methanogenic reaction process includes at least two reactors, such as figure 1 , figure 2 shown.

[0031] Embodiment 3: The high-speed biological treatment method of kitchen waste in this embodiment is different from the previous embodiments in that: in the anaerobic treatment process, biogas residue floating process is used to process biogas residue and solid digestate. One is to use high pressure The reflux gas blows regularly and powerfully to float all the biogas residue and solid d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com