Preparation method for edaravone

An Edaravone and non-alcoholic technology, which is applied in the field of preparation of Edaravone, can solve problems such as waste of energy consumption, corrosion of equipment, and unsuitability for industrialized production, so as to avoid waste of energy consumption, low cost, and avoid corrosion of equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

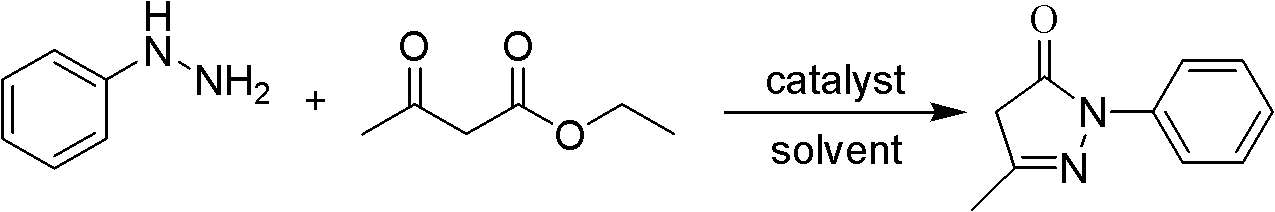

[0023] Embodiment 1: the preparation of Edaravone

[0024] In a 1L four-neck round-bottom flask, add 200ml of ethanol, add 100g (0.9247mol) of phenylhydrazine (0.9247mol), 120.3g (0.9247mol) of ethyl acetoacetate and 10ml of acetic acid successively under stirring at room temperature, protect the temperature with nitrogen, and gradually raise the temperature to 75-80 ℃, stop heating after reacting for 1h, continue stirring and cooling to 60℃, add 50ml of n-hexane, cool to 10℃, keep stirring and crystallizing at the temperature for 1h, filter under reduced pressure, wash and filter with 100ml of ethanol, 100ml of n-hexane and 100ml of ethanol in turn The cake was dried under reduced pressure for 3 hours at a pressure of 1.33-3.33kpa and a temperature of 90°C to obtain 151.7g of crude Edaravone with a yield of 94.2% and a purity of 99.39% by HPLC.

Embodiment 2

[0025] Embodiment 2: the preparation of Edaravone

[0026] In a 1L four-neck round-bottom flask, add 150ml of methanol, and then add 100g (0.9247mol) of phenylhydrazine (0.9247mol), 120.3g (0.9247mol) of ethyl acetoacetate and 20g of tartaric acid under stirring at room temperature. ℃, stop heating after reacting for 1h, continue to stir and cool to 60°C, add 80ml of methyl tert-butyl ether, cool to 10°C, keep stirring and crystallizing for 1h at the temperature, filter under reduced pressure, use ethanol 100ml, methyl tert-butyl ether successively Wash the filter cake with 100ml of base ether and 100ml of ethanol, and dry under reduced pressure for 3 hours at a pressure of 1.33-3.33kpa and a temperature of 90°C to obtain 148.4g of crude product Edaravone, with a yield of 92.1% and a purity of 99.55% by HPLC. .

Embodiment 3

[0027] Embodiment 3: the preparation of Edaravone

[0028] In a 5L four-neck round bottom flask, add 1L isopropanol, add 500g (4.624mol) of phenylhydrazine (4.624mol), 601.7g (4.624mol) of ethyl acetoacetate and 50g of tartaric acid successively under stirring at room temperature, protect the temperature with nitrogen, and gradually heat up to 75 ~80°C, stop heating after reacting for 1h, continue to stir and cool to 60°C, add 300ml of methyl tert-butyl ether, cool to 10°C, keep stirring and crystallizing for 1h at the temperature, filter under reduced pressure, use ethanol 500ml, methyl 500ml of tert-butyl ether and 500ml of ethanol washed the filter cake, and at a pressure of 1.33 to 3.33kpa and a temperature of 90°C, dried under reduced pressure for 3h to obtain 753.1g of crude product Edaravone, with a yield of 93.5%. The HPLC detected purity was 99.32%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com