Nylon 66 resin, nylon 66 filament and preparation method thereof

A technology of nylon and resin, applied in the field of spinning materials, to achieve the effect of simple process, low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046]

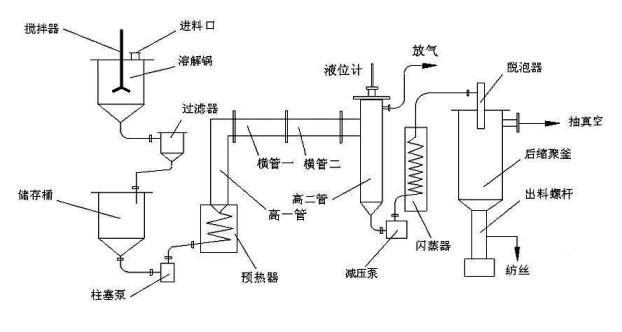

[0047] Such as figure 1 Shown: Stir and mix the above materials and distilled water in a storage tank evenly (the temperature is controlled at about 95°C), so that the concentration of the nylon 66 salt aqueous solution is maintained at about 60%. The above-mentioned materials are continuously fed into the preheater through the plunger pump, and after being preheated to 210°C, they enter the first tube and are continuously pushed into the first and second horizontal tubes, and the first tube enters the horizontal tube. , The material is maintained at 235-240℃, and then the material is pushed into the second pipe. After the material enters the second pipe, the temperature is controlled between 258-263℃. The water vapor in the material is evaporated and discharged through the exhaust pipe; nylon 66 salt The concentration increases, and polycondensation starts (the temperature is maintained at 258℃-262℃); the polymer melt enters the flash evaporator and the deaerator throu...

Embodiment 2

[0051]

[0052] Such as figure 1 Shown: Stir and mix the above materials and distilled water in a storage tank evenly (the temperature is controlled at about 95°C), so that the concentration of the nylon 66 salt aqueous solution is maintained at about 60%. The above-mentioned materials are continuously fed into the preheater through the plunger pump. After being preheated to 210°C, they enter the first tube and are continuously pushed into the horizontal tube and the horizontal tube. The high tube enters the horizontal tube. , The material is maintained at 238-243℃, and then the material is pushed into the second pipe. After the material enters the second pipe, the temperature is controlled between 260-265℃. The water vapor in the material is evaporated and discharged through the exhaust pipe; nylon 66 salt The concentration increases, and the polycondensation starts (the temperature is maintained at 260-265℃); the polymer melt passes through the decompression pump into the flas...

Embodiment 3

[0056]

[0057] Such as figure 1 Shown: Stir and mix the above materials and distilled water in a storage tank evenly (the temperature is controlled at about 95°C), so that the concentration of the nylon 66 salt aqueous solution is maintained at about 60%. The above-mentioned materials are continuously fed into the preheater through the plunger pump. After being preheated to 225°C, they enter the first tube and are continuously pushed into the first and second horizontal tubes, and the first tube enters the horizontal tube. , The material is maintained at 260-265℃, and then the material is pushed into the second pipe. After the material enters the second pipe, the temperature is controlled between 275-283℃. The water vapor in the material is evaporated and discharged through the exhaust pipe; nylon 66 salt The concentration increases, and the polycondensation starts (the temperature is maintained at 270-275°C); the polymer melt enters the flash evaporator and the deaerator throu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com