Low calcium-aluminum-manganese-iron alloy and preparation method thereof

A technology of manganese-ferroalloy and calcium-aluminum, which is applied in the field of low-calcium-aluminum-manganese-ferroalloy and its preparation. It can solve the problems of easy pulverization of aluminum-iron alloy and aluminum-manganese alloy, affecting the mechanical properties of steel castings, affecting economic benefits, etc., and achieves low cost. , high hit rate, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Add aluminum ingots and metal calcium into an induction furnace at a ratio of 86%: 14%, heat for 40 minutes, keep the temperature at 840° C., pour them out of the furnace into a mold to cast into blocks, and naturally cool to form a high-alumina-calcium alloy.

[0024] (2) 50% of angle iron: 8% of medium carbon ferromanganese is added to the induction furnace and heated for 35 minutes. The temperature is maintained at 1600 ° C. Add 40% of the prepared high-aluminum calcium alloy for smelting for 20 minutes. Turn off the power and add 2% The aluminum ingots are naturally cooled to 1100°C and poured into a mold to be cast into a block, and naturally cooled to make a low-calcium aluminum-manganese-ferroalloy.

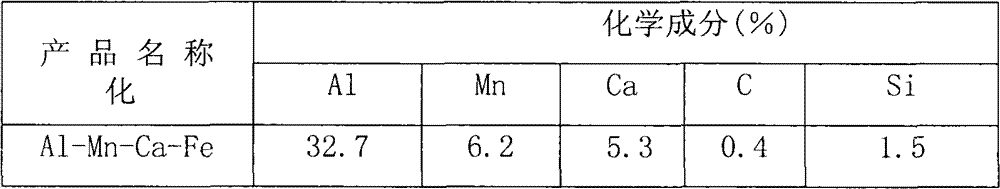

[0025] The chemical composition of the obtained low-calcium Al-Mn-Fe alloy: (all are weight percent):

[0026]

[0027] The balance is Fe.

Embodiment 2

[0029] (1) The ratio of 90% aluminum ingot: 10% calcium metal is added to the induction furnace and heated for 40 minutes, the temperature is maintained at 850° C., the furnace is poured into a mold to cast into a block, and naturally cooled to form a high-alumina-calcium alloy.

[0030] (2) Angle iron 10%: the ratio of medium carbon ferromanganese 9% is added to the induction furnace and heated for 35 minutes, the temperature is maintained at 1580 ° C, and 78% of the obtained high-alumina-calcium alloy is added for smelting for 18 minutes, the power is turned off, and 3% is added The aluminum ingots are naturally cooled to 1060°C, poured into a mold and cast into blocks, and naturally cooled to make a low-calcium aluminum-manganese-ferroalloy.

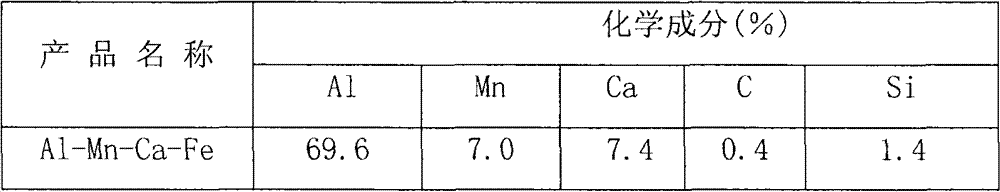

[0031] The chemical composition of the obtained low-calcium Al-Mn-Fe alloy: (all are weight percent):

[0032]

[0033] The balance is Fe.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com