Modularized forming machine waste heat recovery machine

A setting machine and modular technology, applied in indirect heat exchangers, heating/cooling fabrics, lighting and heating equipment, etc., can solve problems such as unfavorable sustainable development, fire hazards, increased production costs, etc., to ensure heat recovery efficiency , Improve heat recovery rate, save production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

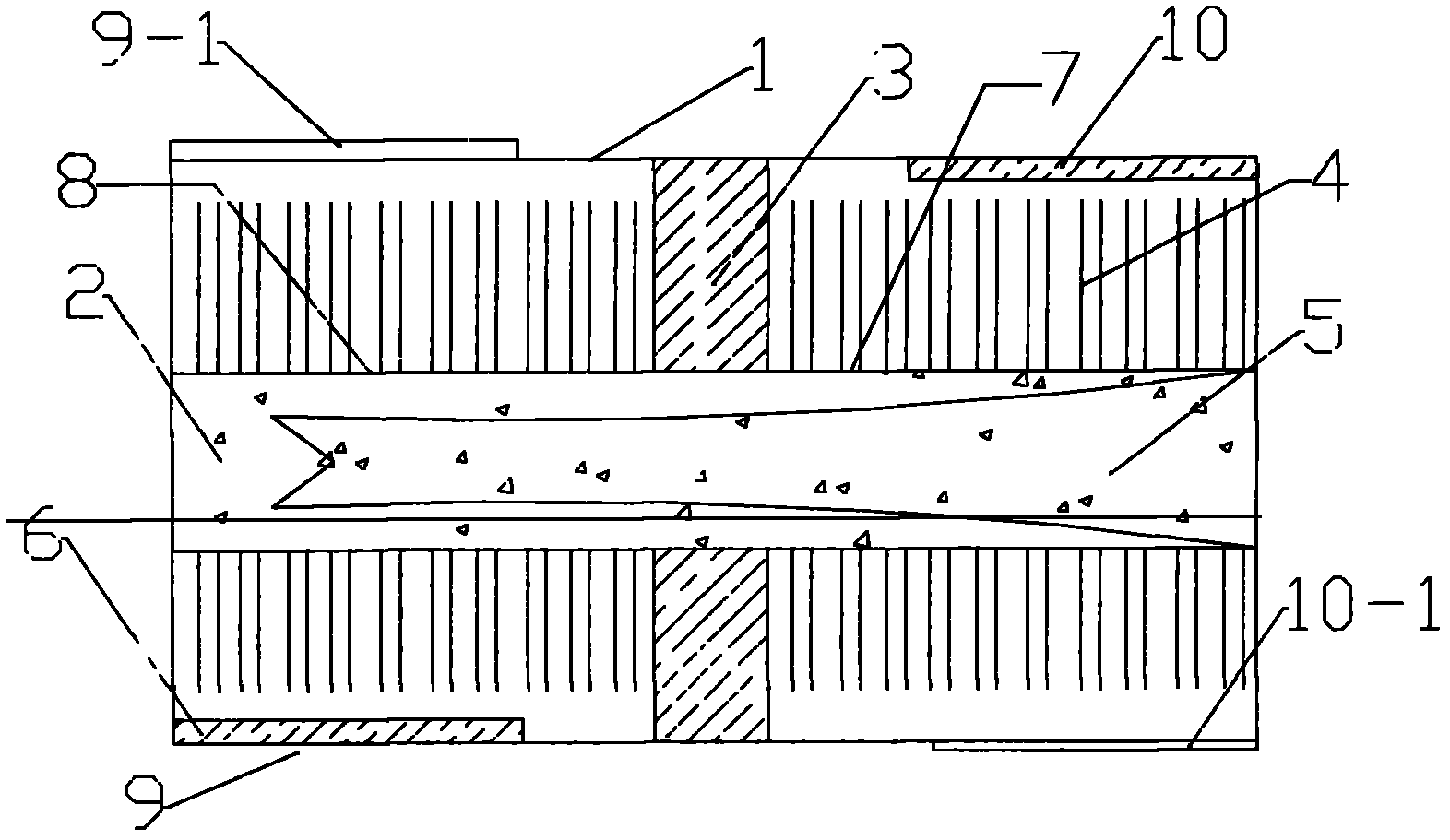

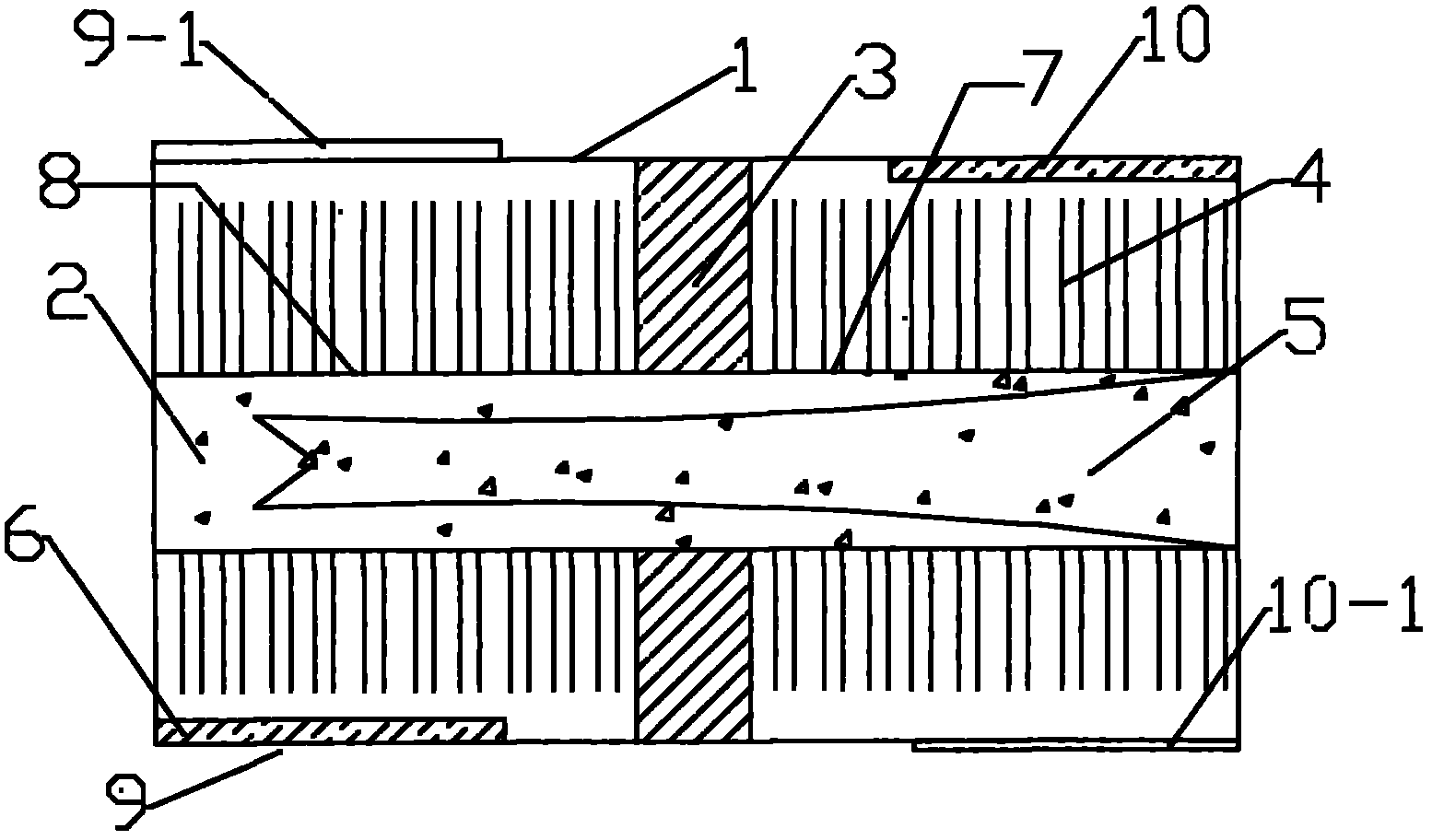

[0024] Such as figure 1 As shown, the present invention relates to a waste heat recovery machine of a modular setting machine, which includes a casing 1 and a heat exchange device, and the casing 1 is provided with an exhaust gas inlet 9, an exhaust gas outlet 9-1, a fresh air inlet 10 and a fresh air outlet 10-1, the heat exchange device includes a heat pipe 2, a partition 3 and fins 4, the partition 3 is arranged on the heat pipe 2, the fins 4 are arranged on both sides of the heat pipe 2 body, the heat pipe 2 It is vacuum, and it is filled with working fluid, and the working fluid is heat conduction oil 5 .

[0025] Wherein, the exhaust gas inlet 9 is provided with a filter screen 6, and the filter screen 6 is double-layer; the fresh air inlet 10 is provided with a filter screen 6, and the filter screen 6 is double-layer;

[0026] In the present invention, a heat pipe heat exchanger is adopted, so that the recovery efficiency is high, the recovery efficiency can be above 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com