Lithium iron phosphate lithium ion battery and machining method thereof

A lithium-ion battery, lithium iron phosphate technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problem of difficult bonding between positive active materials and current collectors, and achieve good bonding and improve slurry uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

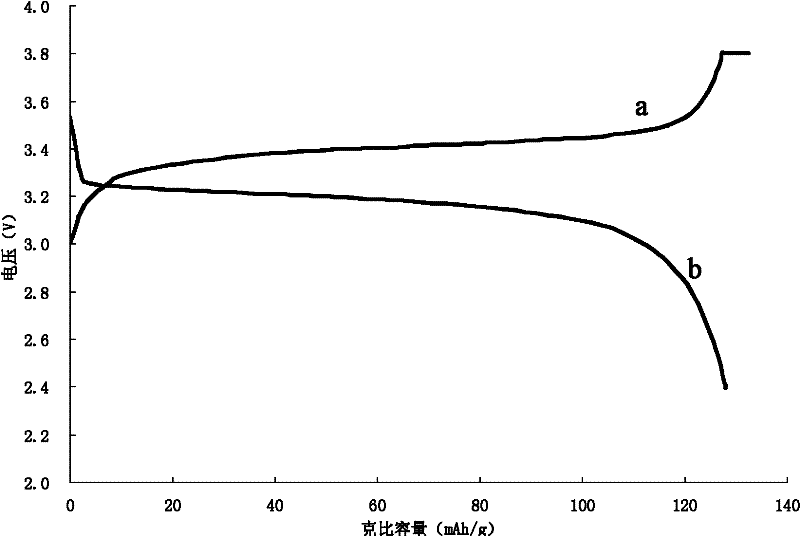

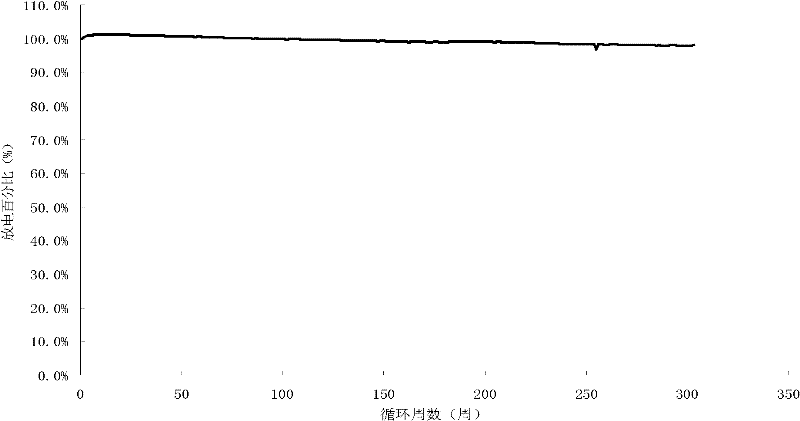

Image

Examples

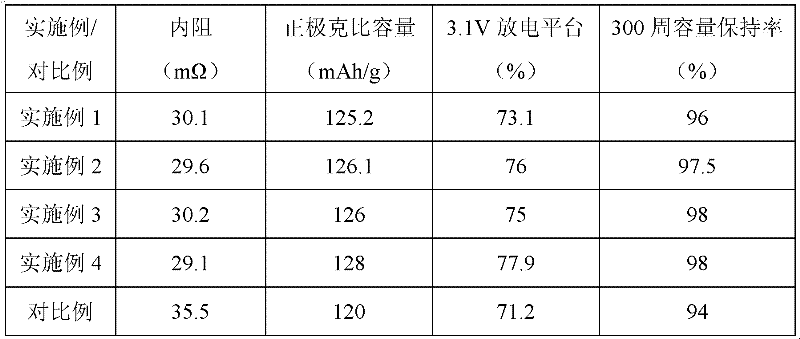

Embodiment 1

[0031] 1. Slurry Preparation

[0032] First, dilute 30g of LA water-based adhesive with 900g of deionized water, stir at a speed of 600r / min for 40min to obtain adhesive, then add 25g of SP and 5g of KS-6 mixed conductive agent into the adhesive in 3 times, Stir in vacuum at a speed of 20000r / min for 60min to make a conductive colloid; then add 900g of lithium iron phosphate to the above conductive colloid in 3 times, adjust to 20-35Hz by revolution, 15-35Hz by rotation, and stir in vacuum for 240min. Obtain positive electrode slurry; sieve to make a slurry with a viscosity of 6000mpa.s.

[0033] 2. Coating

[0034] Adjust the coating temperature to: 80°C for the first section, 90°C for the second section, and 50°C for the third section. After the temperature is stable, apply the prepared slurry evenly on the surface of the aluminum foil, dry it, and finish. Coating the pole piece to obtain the positive pole piece of lithium ion battery made of lithium iron phosphate materia...

Embodiment 2

[0036] Similar to Example 1, the difference is that the binder is changed to 35g.

Embodiment 3

[0038] Similar to Example 1, the difference is that the binder is changed to 40g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com