Minitype composite vibration power generator

A vibration generator and compound technology, applied in the directions of generators/motors, electrical components, electromechanical devices, etc., can solve the problems of hindering development and application, reduce the natural frequency of the structure, small bearing capacity, etc., to expand the operating frequency range, The effect of improving stress conditions and reducing natural frequencies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

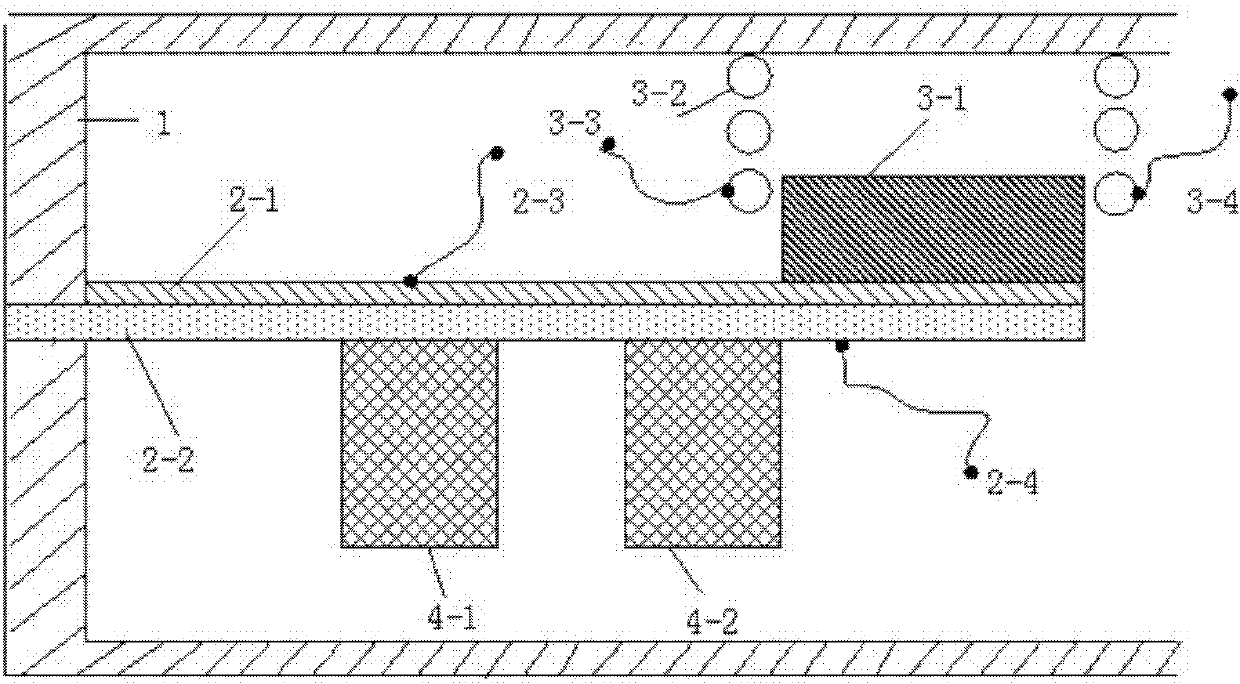

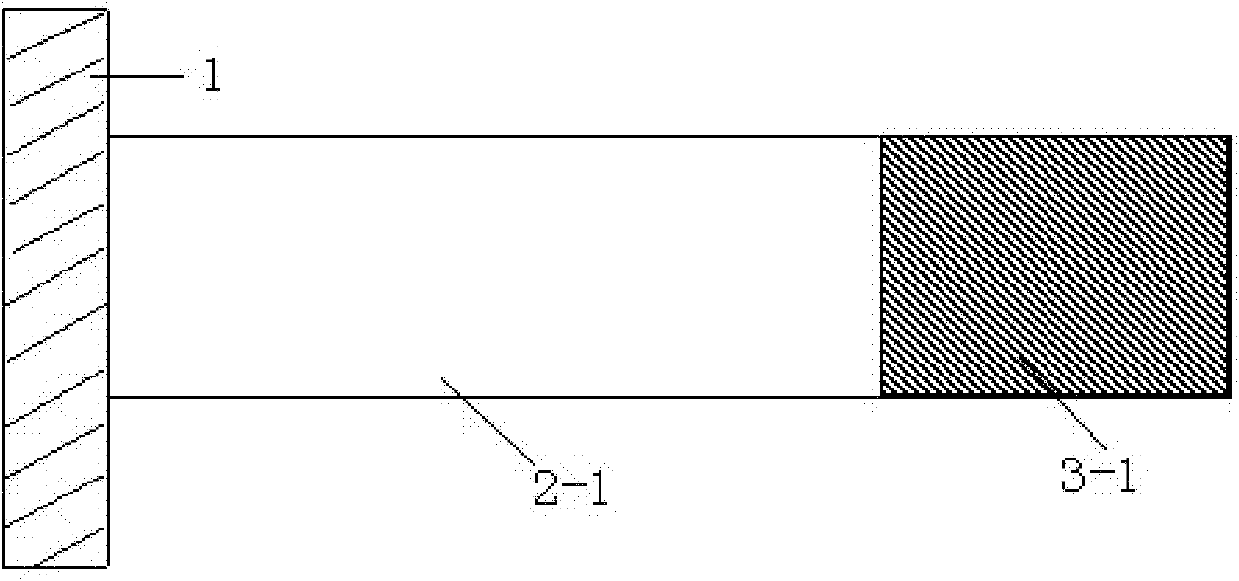

[0035] Such as figure 1 , 2 As shown, the miniature composite vibration generator includes the following parts: an insulating shell 1, a piezoelectric sheet 2-1, a supporting substrate 2-2, piezoelectric generating output wires 2-3, 2-4, a permanent magnet 3-1, Inductance coil 3-2, electromagnetic power generation output wires 3-3, 3-4, dispersed masses 4-1, 4-2, wherein the piezoelectric cantilever beam is composed of a piezoelectric sheet 2-1 and a supporting substrate 2-2, The material of the supporting substrate 2-2 is phosphor bronze, one end of the supporting substrate 2-2 is fixed on the insulating shell 1, the piezoelectric sheet 2-1 is made of PZT-5H material, the polarization direction is the same as the thickness direction, and pasted by conductive adhesive On the upper layer of the supporting substrate 2-2, the permanent magnet 3-1 is pasted on the upper layer of the end of the piezoelectric sheet 2-1, and the electromagnetic coil 3-2 directly above the permanent ...

Embodiment 2

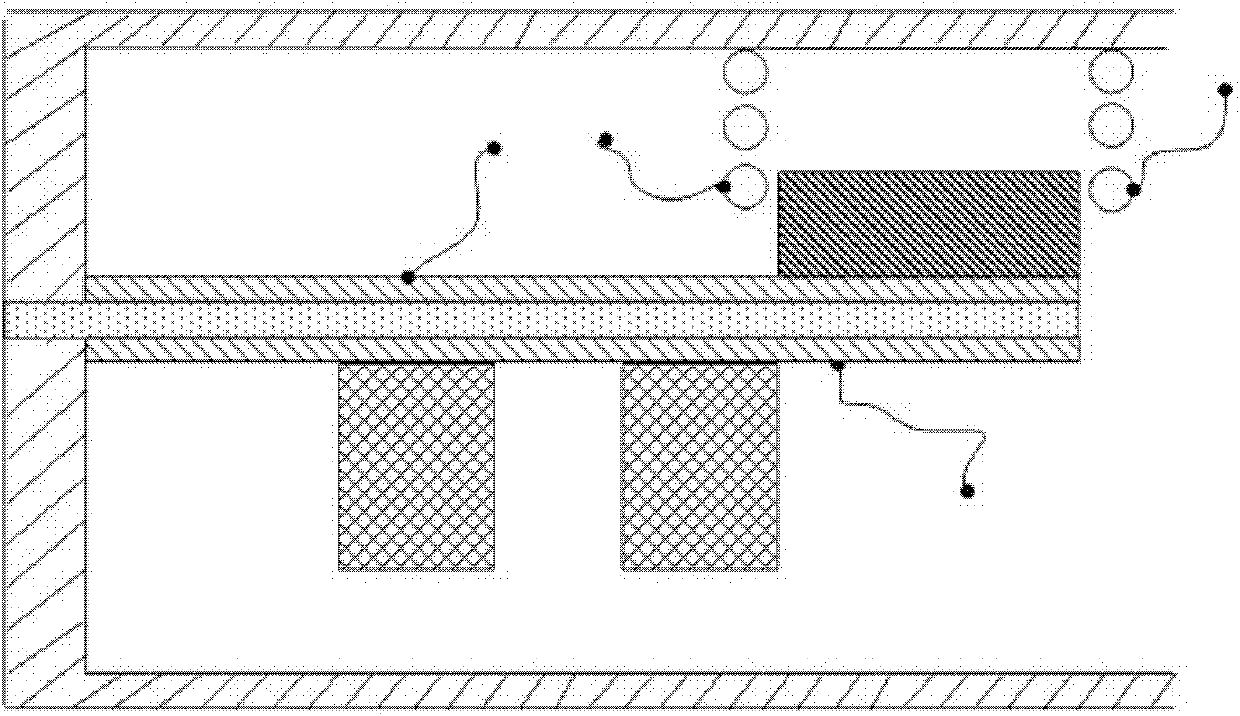

[0039] Such as image 3 As shown, the piezoelectric cantilever beam is composed of two piezoelectric sheets and a supporting substrate, and the piezoelectric sheets are pasted on the upper and lower surfaces of the supporting substrate respectively. Other conditions are identical with embodiment 1.

Embodiment 3

[0041] Such as Figure 4 As shown, there are two masses, which are pasted on the upper and lower surfaces of the piezoelectric cantilever respectively. Other conditions are identical with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com