Bone peptide composition, preparation thereof, preparation method thereof and application

A technology of composition and osteopeptide, which is applied in the field of preparation, osteopeptide composition and preparation thereof, can solve the problems of long extraction process time, influence of extract biological activity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

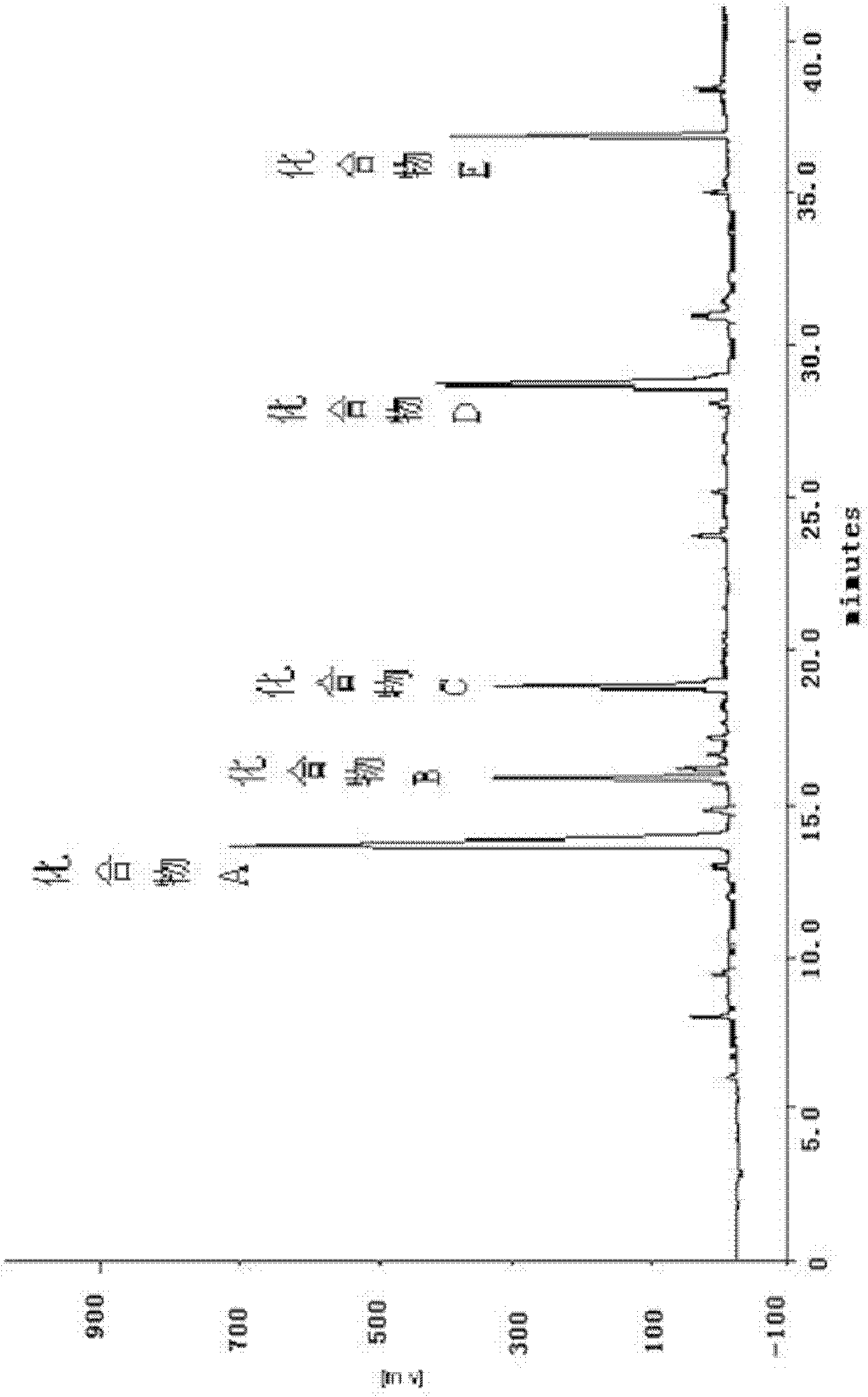

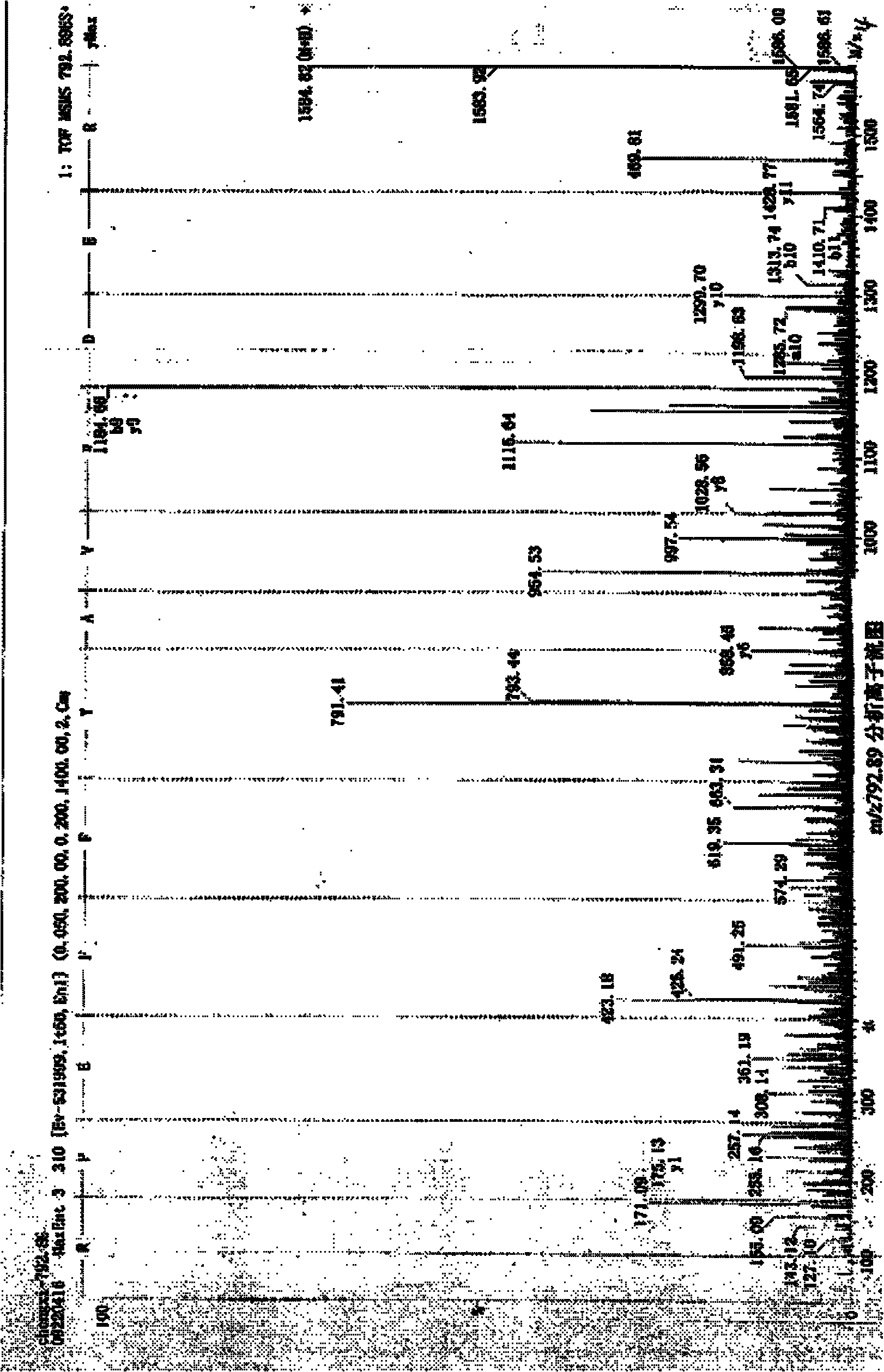

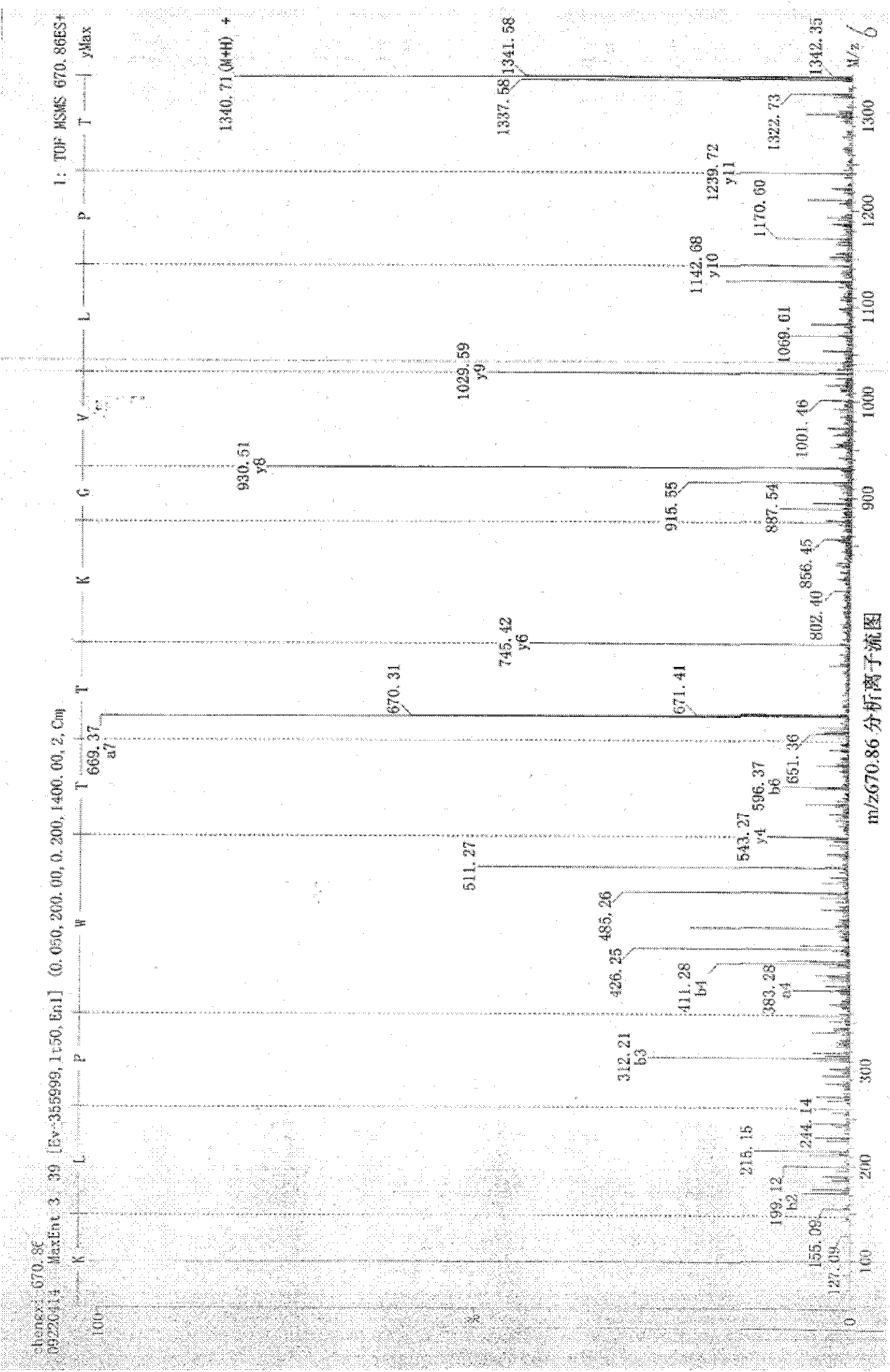

Image

Examples

Embodiment 1

[0077] A method for preparing an osteopeptide composition includes the following steps:

[0078] 1. Take healthy fresh frozen pork limb bones, wash and crush;

[0079] 2. Grind the crushed limb bones into bone mud with a bone mud machine, put it in an extraction tank, add 3 times the amount of water, heat and stir at 80°C for 2 hours, take the supernatant and store; add 2 times the amount of the obtained bone residue Heat and stir water at 80°C for 1 hour, take the supernatant; combine the supernatants obtained twice and concentrate under reduced pressure at 60°C to the weight of the raw material;

[0080] 3. Place the solution obtained in step 2 at 0°C for 12 hours to remove the upper layer of fat;

[0081] 4. The solution is adjusted to pH 4.5 with hydrochloric acid, heated and boiled for 15 minutes, filtered, and cooled, placed at 0°C for 12 hours, and centrifuged after removing the upper layer of fat; the centrifugal condition is 2000 rpm and the time is 30 minutes;

[0082] 5. The...

Embodiment 2

[0090] A method for preparing an osteopeptide composition includes the following steps:

[0091] 1. Take the limb bones of healthy and freshly frozen pigs, wash and crush;

[0092] 2. The crushed limb bones are ground into bone mud with a bone mud machine. The bone mud is microwaved. The microwave power is 450W and the action time is 5 minutes. Then put it into the extraction tank, add 6 times the amount of water, and keep it warm at 100°C. Stir for 1 hour, take the supernatant and store; add 4 times the amount of water to the obtained bone residue, keep stirring at 100°C for 1 hour, and take the supernatant; combine the supernatant obtained twice and concentrate under reduced pressure at 60°C to the weight of the raw material;

[0093] 3. Place the solution obtained in step 2 at 0°C for 12 hours to remove the upper layer of fat;

[0094] 4. The solution is adjusted to pH 4.5 with hydrochloric acid, heated and boiled for 20 minutes, filtered and cooled, and placed at 0°C for 12-24 hou...

Embodiment 3

[0103] A method for preparing an osteopeptide composition includes the following steps:

[0104] 1. Take the limb bones of healthy freshly frozen fetal cattle, wash and crush;

[0105] 2. The crushed limb bones are ground into bone mud with a bone mud machine. The bone mud is microwaved. The microwave power is 450W and the action time is 15 minutes. Then put it into the extraction tank, add 4 times the amount of water, and keep it warm at 90°C. Stir for 1.5 hours, take the supernatant and store; add 3 times the amount of water to the obtained bone residue, keep at 90°C and stir for 1.5 hours, and take the supernatant; combine the supernatant obtained twice and concentrate under reduced pressure at 60°C to the weight of the raw material;

[0106] 3. Place the solution obtained in step 2 at 0°C for 18 hours to remove the upper layer of fat;

[0107] 4. The solution is adjusted to pH 5.0 with hydrochloric acid, heated and boiled for 20 minutes, filtered, cooled, and placed at -5°C for 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com