Method for preparing injectable microgelparticles

A technology for injection and gel, which is applied in the field of preparation of injectable gel particles to achieve the effects of avoiding pollution, short time-consuming, and convenient replacement of dialysate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

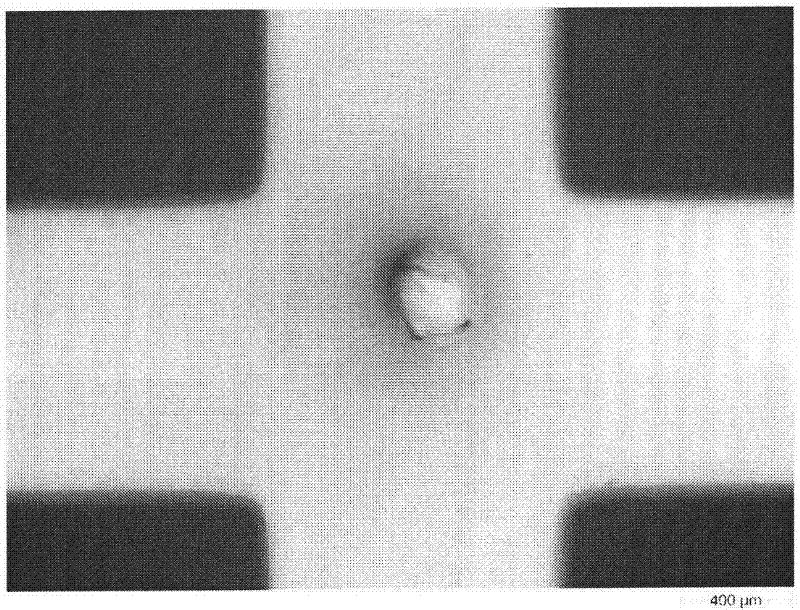

Image

Examples

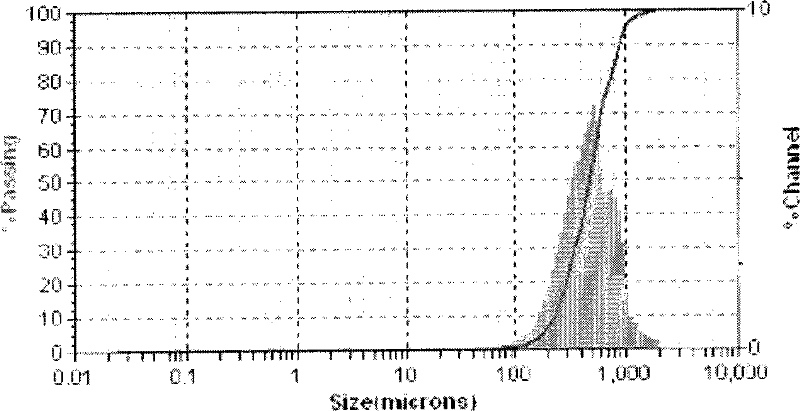

Embodiment 1

[0021] Dissolve 5.0 grams of hyaluronic acid dry powder with an average molecular weight of 1.2 million Daltons in 0.1M NaOH solution, stir at a speed of 90 rpm for 5 minutes, and configure a hyaluronic acid with a concentration of 10% (W / W) To the alkaline solution, 10.0 g of butanediol diglycidyl ether (BDDE) was added, stirred and placed in a thermostat at 40 degrees Celsius for 4 hours to form an alkaline cross-linked hyaluronic acid gel. Put the gel into a 1L cylindrical airtight container, use a peristaltic pump as the power, pass through PBS buffer at a speed of 60ml / min, and dialyze for 4 days. After the dialysis is completed, put it into a rotary chopper, add PBS buffer solution at a ratio of 1:1 by weight, and rotate at 8,000 to chop for 60 seconds. After chopping, the solution is centrifuged at 5,000 rpm for 30 minutes to remove the upper dispersion solution to obtain injectable gel particles. After testing, the concentration of the hyaluronic acid gel particles is...

Embodiment 2

[0023] Dissolve 5.0 grams of hyaluronic acid dry powder with an average molecular weight of 1.25 million Daltons in 0.125M NaOH solution, stir at a speed of 120 rpm for 4 minutes, and configure a hyaluronic acid with a concentration of 12.5% (W / W) To the alkaline solution, 7.5 grams of butanediol diglycidyl ether (BDDE) was added, and after stirring, it was placed in a thermostat at 40 degrees Celsius for 5 hours to form an alkaline cross-linked hyaluronic acid gel. Put the gel into a 1L cylindrical airtight container, use a peristaltic pump as the power, pass through PBS buffer at a speed of 30ml / min, and dialyze for 5 days. After the dialysis is completed, put it into a rotary chopper, add PBS buffer solution at a ratio of 1:1 by weight, and rotate at 9,000 to chop for 60 seconds. After the minced solution is centrifuged at 8,000 rpm for 10 minutes, the upper dispersion solution is removed to obtain injectable gel particles. After testing, the concentration of the gel is ...

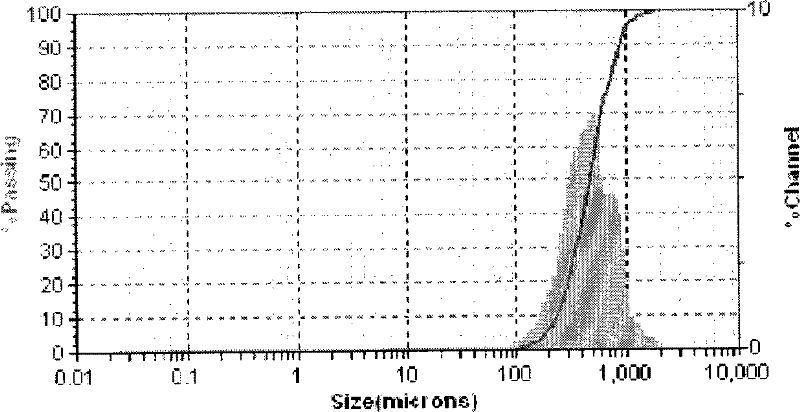

Embodiment 3

[0025] Dissolve 5.0 grams of hyaluronic acid dry powder with an average molecular weight of 1.1 million Daltons in 2.0M Na 2 CO 3 In the solution, stir at a speed of 60 rpm for 8 minutes, configure a hyaluronic acid alkaline solution with a concentration of 5.0% (W / W), add 0.5 g of divinyl sulfone (DVS), and put it in 35 degrees Celsius after stirring. After 4 hours in a constant temperature box, an alkaline cross-linked hyaluronic acid gel is formed. Put the gel into a 1L cylindrical airtight container, use a peristaltic pump as the power, pass through PBS buffer at a speed of 40ml / min, and dialyze for 5 days. After the dialysis is completed, put it into a rotary chopper, add PBS buffer solution at a ratio of 1:1 by weight, and rotate at 8,000 to chop for 60 seconds. After the minced solution is centrifuged at 10,000 rpm for 10 minutes, the upper dispersion solution is removed to obtain injectable gel particles. After testing, the gel concentration was 1.98 mg / ml, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com