Preparation method of intermediate-polarity macroporous adsorption resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

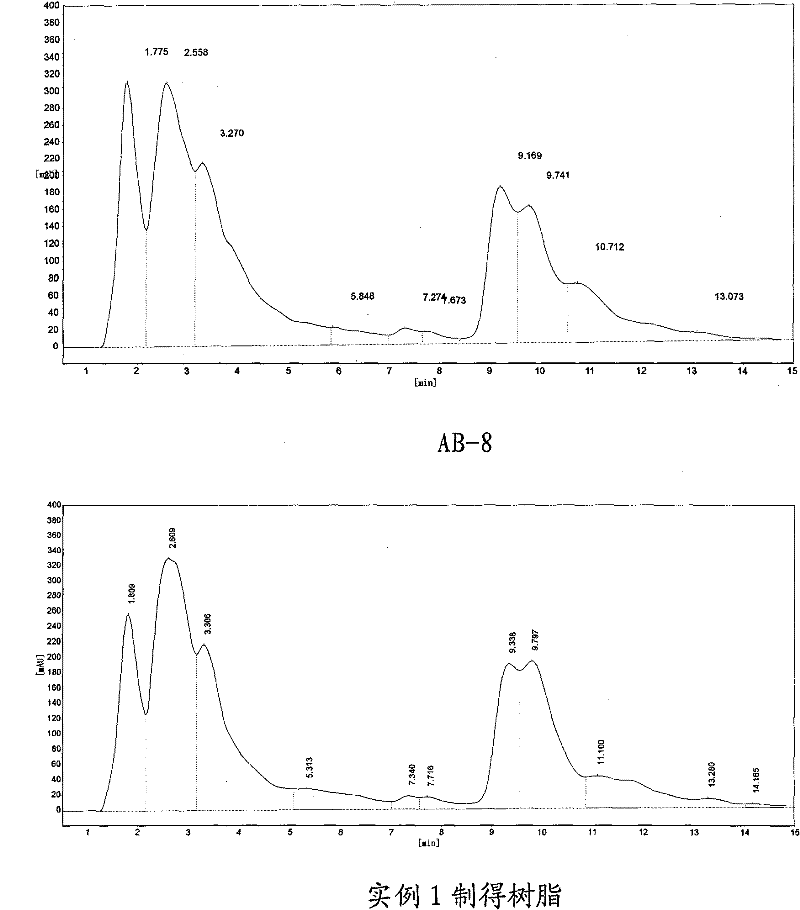

Embodiment 1

[0018] Take 10 grams of styrene, 15 grams of hydroxyethyl acrylate, 75 grams of divinylbenzene with a weight percentage of 80%, 133.3 grams of toluene, 66.6 grams of octanol, and 1 gram of benzoyl peroxide, and mix them uniformly to obtain an oil phase. Take 500ml of deionized water, add 2 grams of polyvinyl alcohol, 5 grams of gelatin, and 100 grams of sodium chloride, stir to dissolve, and obtain an aqueous phase. Take 200 grams of the previously prepared oil phase and put it into the water phase, turn on the agitator at a speed of 60 rpm, and when the diameter of the oil beads is 1.2mm, start to slowly heat up, and react at a constant temperature for 2 hours at 78°C, with a heating rate of 0.5°C / min; continue to react at constant temperature for 2 hours after the beads are finalized. Then raise the temperature to 88°C at the same heating rate, and then react at a constant temperature for 6 hours; then raise the temperature to 95°C at the same heating rate, react at a consta...

experiment example 2

[0021] Take 40 grams of styrene, 10 grams of hydroxyethyl acrylate, 50 grams of divinylbenzene with a weight percentage of 80%, 150 grams of toluene, 150 grams of octanol, and 1 gram of benzoyl peroxide, and mix them uniformly to obtain an oil phase. Get 500ml deionized water, add 2 grams of polyvinyl alcohol, 5 grams of gelatin, 100 grams of sodium chloride, stir and dissolve, and obtain the aqueous phase. Take 200 grams of the previously prepared oil phase and put it into the water phase, turn on the agitator at a speed of 60 rpm, and when the diameter of the oil beads is 1.2mm, start to slowly heat up, and react at a constant temperature for 2 hours at 78°C, with a heating rate of 0.5°C / min; continue to react at constant temperature for 2 hours after the beads are finalized. Then raise the temperature to 88°C at the same heating rate, and then react at a constant temperature for 6 hours; then raise the temperature to 95°C at the same heating rate, react at a constant temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com