Glutinous-rice-fermented beverage

A fermented, glutinous rice technology, applied in food preparation, application, food science and other directions, can solve the problems of not meeting consumers' pursuit of green food, not meeting consumers' taste needs, single rice wine products, etc., to achieve pure taste, The effect of long fermentation time and low alcohol content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

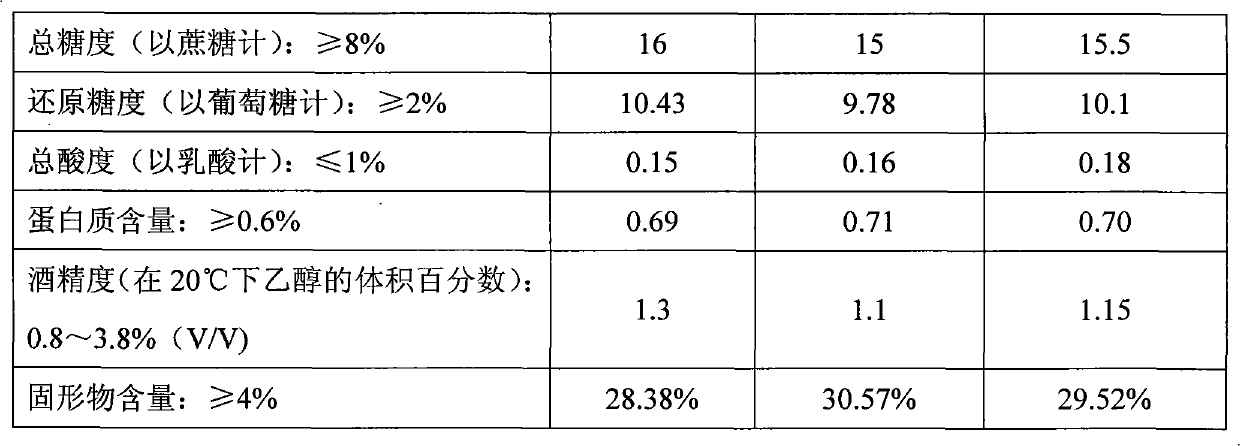

Embodiment 1

[0015] The glutinous rice fermented drink is prepared according to the following steps: (1) wash the high-quality glutinous rice, soak it in water for 28 hours, steam the soaked glutinous rice, and lower the temperature to 26°C; (2) add 0.5% of the dry weight of the glutinous rice after cooling Distiller's koji, after mixing evenly, put in cans in a fully sealed environment, ferment for 36 hours at 30°C, turn over the glutinous rice in the tank, continue to place the tank in a fully sealed environment and ferment for 36 hours at 30°C to form distiller's grains; (3) Refining the distiller's grains, adding the configured liquid (A), the liquid (A) includes per 10 kg of glutinous rice: 2 kg of white sugar, 0.1 kg of nutrient agar and 30 kg of purified water, and the liquid (A) is mixed with the ground The distiller's grains after the slurry are mixed evenly and heated and stirred to make it form an emulsion. The concentration of solids in this emulsion is 25wt%. The pH of the emul...

Embodiment 2

[0017] The glutinous rice fermented beverage is prepared according to the following steps: (1) wash the glutinous rice for brewing, soak it in water for 32 hours, steam the soaked glutinous rice, and lower the temperature to 28°C; Add distiller's yeast, mix evenly, place in a fully sealed environment, ferment for 32 hours at 27°C, turn over the glutinous rice in the tank, continue to place the tank in a fully sealed environment, and ferment for 38 hours at 27°C to form distiller's grains; (3 ) refining the above distiller's grains, adding the configured liquid (A), the liquid (A) includes: 3 kg of white granulated sugar, 0.2 kg of nutrient agar, and 40 kg of purified water, and the liquid (A) is mixed with The distiller's grains after refining are mixed evenly and heated and stirred to make it form an emulsion, the concentration of solids in this emulsion is 30wt%, the pH of the adjusted emulsion is 4.5, the sugar content is 15 ° Brix, and then the pressure is 20Mpa (4) Keep t...

Embodiment 3

[0019] The glutinous rice fermented drink is prepared according to the following steps: (1) wash the glutinous rice for brewing, soak it in water for 36 hours, steam the soaked glutinous rice, and cool down to 30°C; Add distiller's koji, mix evenly, place in a fully sealed environment, ferment for 36 hours at 30°C, turn over the glutinous rice in the tank, continue to place the tank in a fully sealed environment, and ferment for 40 hours at 30°C to form distiller's grains; (3 ) refining the above distiller's grains, adding the prepared liquid (A), the liquid (A) includes per 10 kg of glutinous rice: 4 kg of white granulated sugar, 0.25 kg of nutrient agar and 50 kg of purified water, and the liquid (A) is mixed with The distiller's grains after refining are mixed evenly and heated and stirred to form an emulsion, the concentration of solids in the emulsion is 35wt%, the pH of the emulsion is adjusted to be 4.4, the sugar content is 15.5°Brix, and the pressure is 30Mpa (4) Keep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com