Automatic spraying process for precision hardware and spraying control method

A technology of automatic spraying and control system, applied in the direction of coating, spraying device, liquid spraying device, etc., can solve problems such as increasing production difficulty, and achieve the effect of increasing production difficulty, increasing production capacity, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

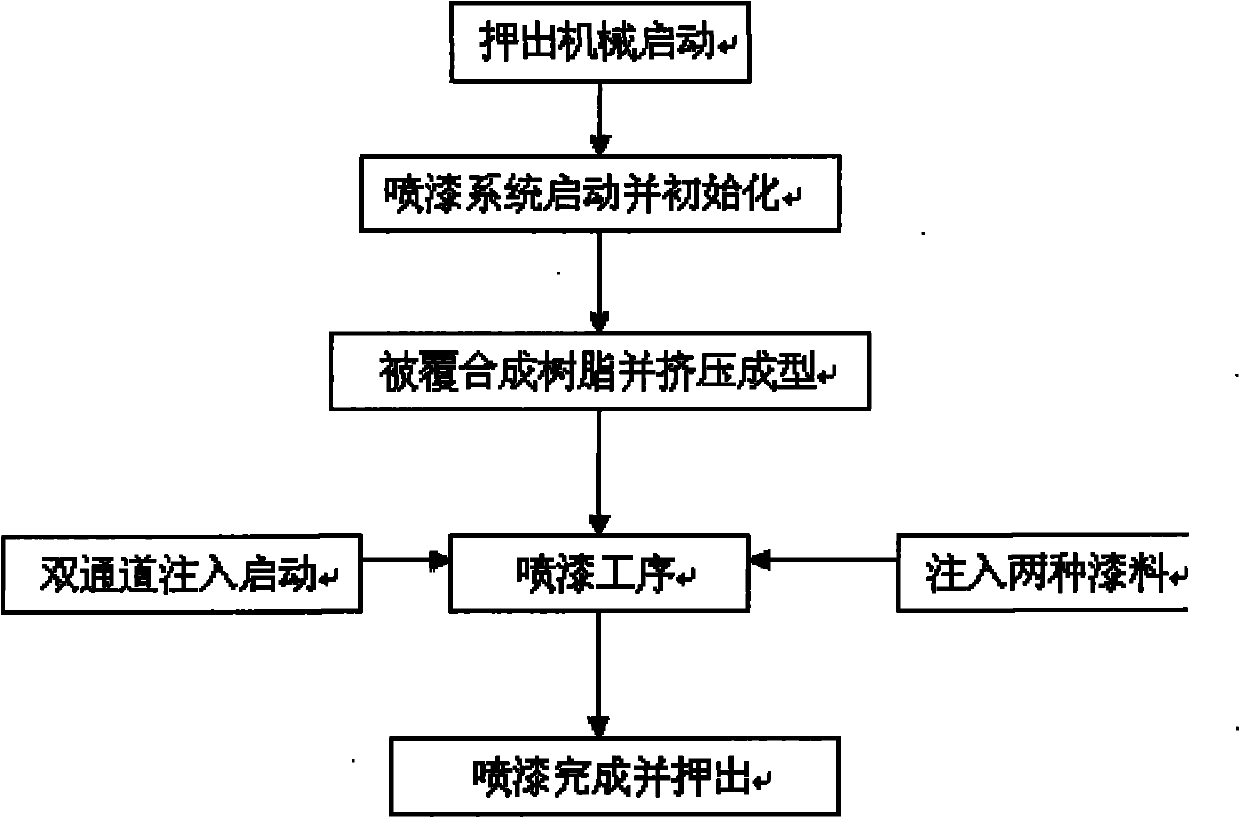

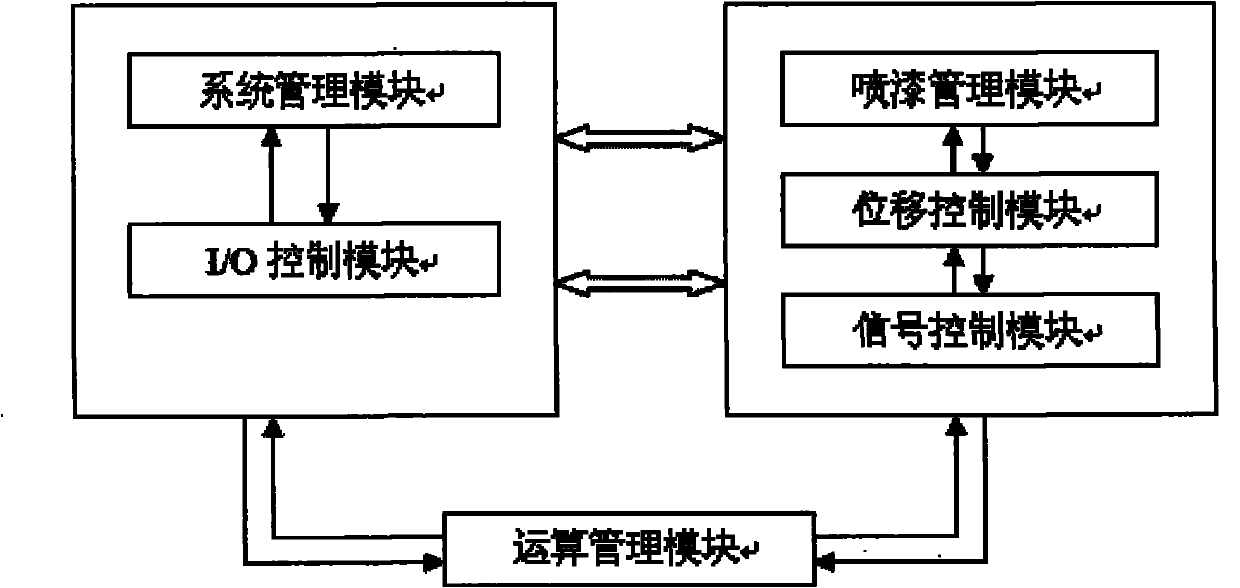

[0031] see figure 1 , an automatic spraying process for precision hardware, the method comprising the following steps:

[0032] (1) Set up product automatic spraying production line and sensor equipment, core component precision gear pump, spraying control system and electrostatic generator device;

[0033] (2) Set up bilateral docking sensors and multi-line configuration embedded control system, and cooperate with electric elevators to realize automatic control of the spraying process;

[0034] (3) The production line adopts tunnel mode, and one or more processing procedures are carried out at each stage. According to the specific spraying process, several layers of spraying process are completed in sequence from inner layer oily spraying to surface plating spraying, so that it can be applied on structural parts. A composite coating is formed on the surface;

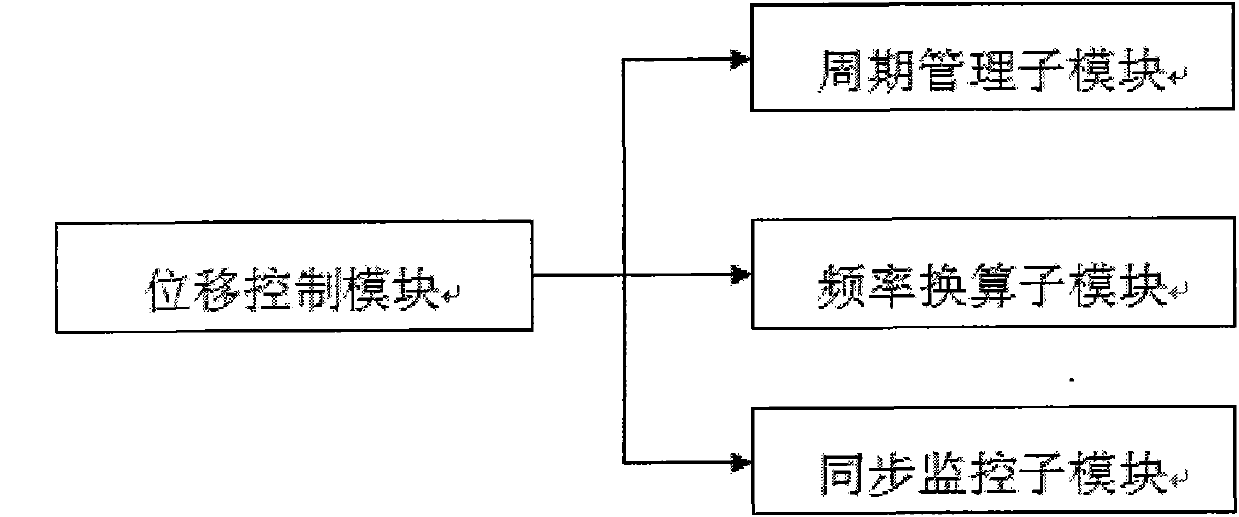

[0035](3) The spraying control system is divided into multiple bands that can be set at will, and the running speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com