Preparation method for acrylic acid microemulsion with self-crosslinking core-shell structure

A core-shell structure, micro-emulsion technology, applied in coatings and other directions, can solve problems such as reducing water resistance and restricting applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

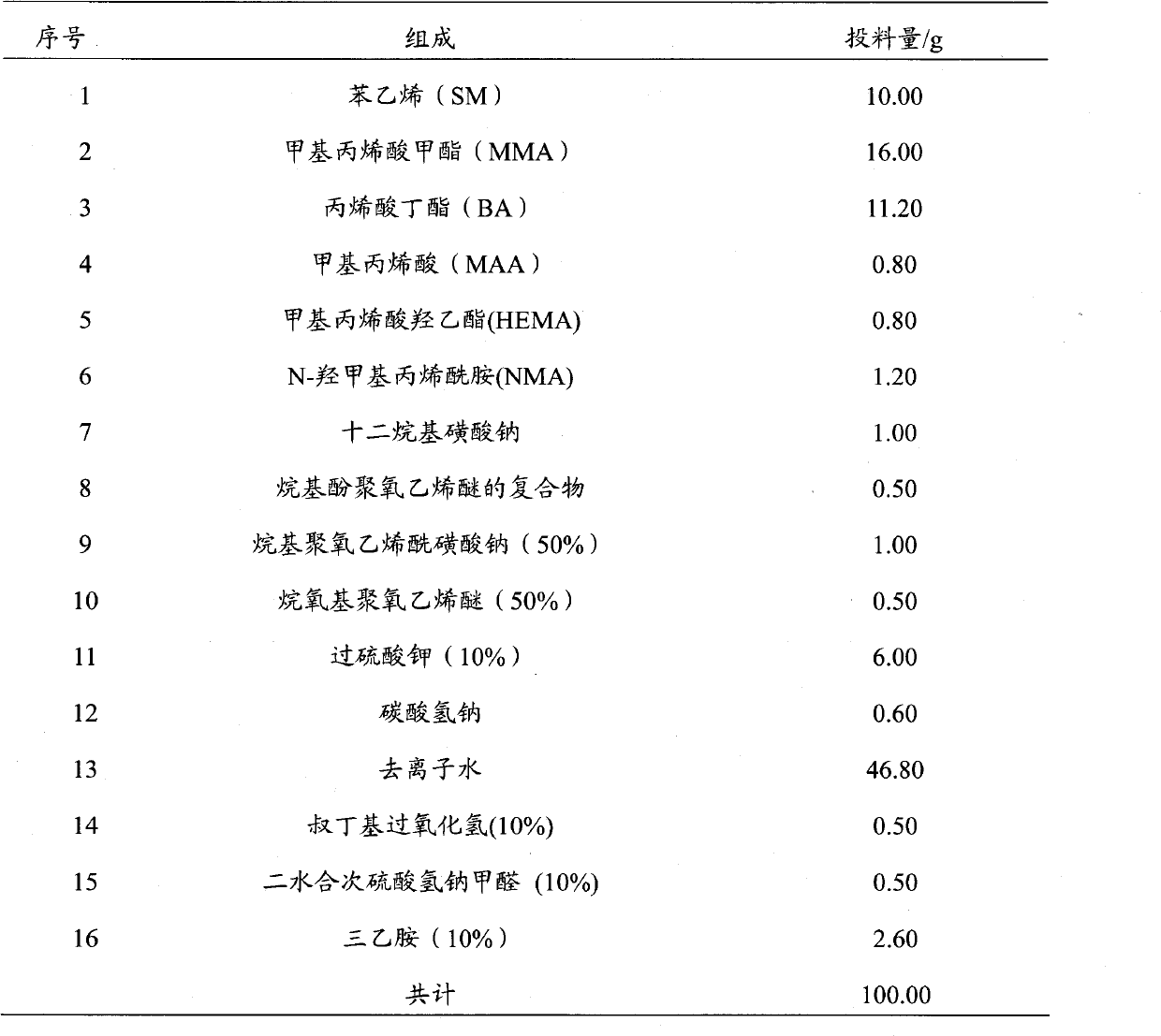

[0048] Select each component composition and content in this implementation as shown in Table 1:

[0049] Table 1 Embodiment 1 each component composition and content table

[0050]

[0051] A preparation method of self-crosslinking core-shell structure acrylic acid microemulsion, comprising the following steps in order:

[0052] Step 1, pre-emulsification of seed microemulsion monomer

[0053] Add 1.00g of anionic emulsifier sodium dodecylsulfonate and 0.50g of OP-10, 0.60g of pH value buffer sodium bicarbonate and 32.45g of deionized water into the emulsifier, and mix for 10 minutes under stirring at 1000 rpm; Take vinyl monomer, that is, 2.40g methyl methacrylate, 1.50g styrene, and 0.40g butyl acrylate, mix them evenly, and drop them into the emulsifier at a constant speed under the condition of 7500 rpm high-speed emulsification, and the dropping time is 30 minutes Continue high-speed emulsification for 30 minutes after dropping to obtain the pre-emulsion of the seed ...

Embodiment 2

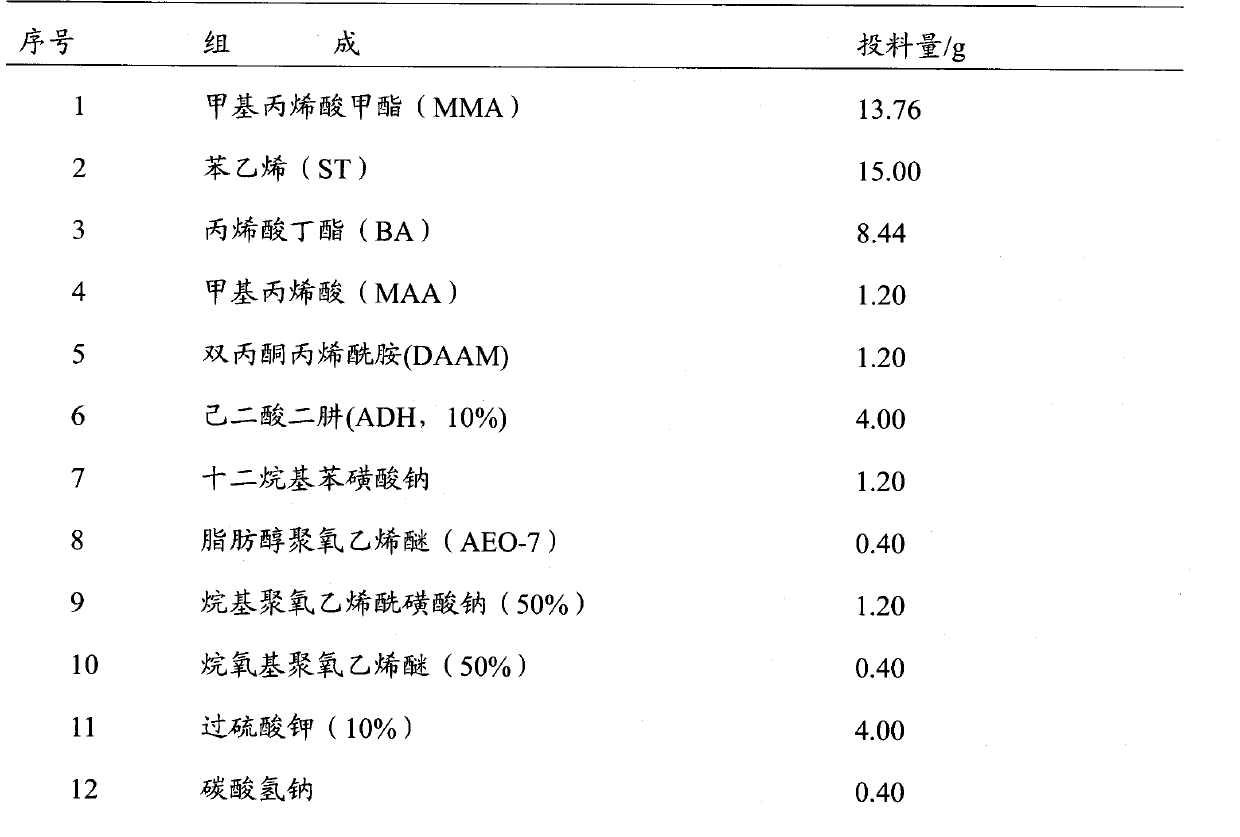

[0063] Select each component composition and content in this implementation as shown in Table 2:

[0064] Each component composition and content table of table 2 embodiment 2

[0065]

[0066]

[0067] A preparation method of self-crosslinking core-shell structure acrylic acid microemulsion, comprising the following steps in order:

[0068] Step 1, the pre-emulsification of seed microemulsion monomer 1.20g anionic emulsifier sodium dodecylsulfonate and 0.40g fatty alcohol polyoxyethylene ether (AEO-7), 0.40gpH value buffer sodium bicarbonate and 27.11g Add deionized water into the emulsifier, and mix for 5 minutes at 1200 rev / min stirring condition; get vinyl monomer, i.e. 1.38g methyl methacrylate, 1.50g styrene, 0.19g butyl acrylate and mix evenly. Under the condition of 10000 rpm high-speed emulsification, it was dripped into the emulsifier at a constant speed, and the dripping time was 20 minutes; after the dripping, the high-speed emulsification was continued for 2...

Embodiment 3

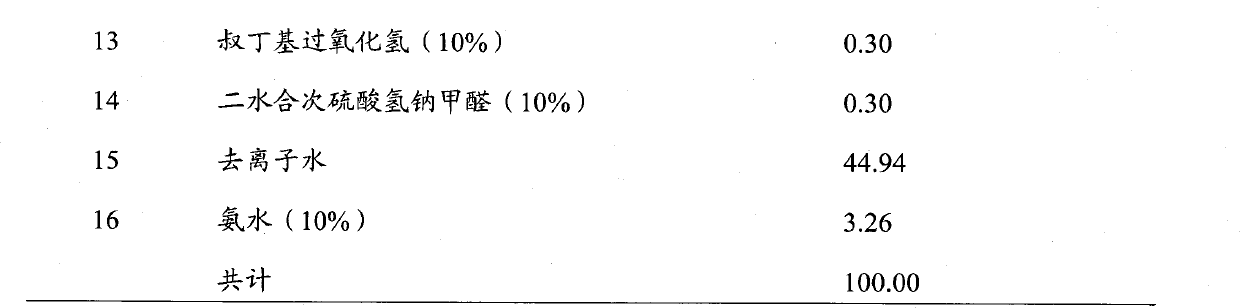

[0078] Select each component composition and content in this implementation as shown in Table 3:

[0079] Table 3 Embodiment 3 each component composition and content table

[0080]

[0081]

[0082] A preparation method of self-crosslinking core-shell structure acrylic acid microemulsion, comprising the following steps in order:

[0083] Step 1, pre-emulsification of seed microemulsion monomer

[0084] Add 0.80g of anionic emulsifier lauryl ammonium sulfate and 0.80g of nonionic emulsifier alkylphenol polyoxyethylene ether (TX-100), 0.60g of pH buffer sodium bicarbonate and 30.59g of deionized water into the emulsifier, Mix for 15 minutes under the stirring condition of 800 rpm; take the vinyl monomer, that is, 7.50 g of methyl methacrylate and 0.50 g of butyl acrylate, mix them evenly, and drop them into the emulsifier at a constant speed under the condition of high-speed emulsification at 6000 rpm In, drop time 20 minutes; Continue high-speed emulsification 40 minute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com