Long carbon chain nylon modified phenolic resin and preparation method thereof

A technology of phenolic resin and long carbon chain, which is applied in the field of long carbon chain nylon modified phenolic resin and its preparation, which can solve the problems of reduced wettability of modified resin, reduced operation safety, and consumption of solvents, etc., to stabilize the quality of phenolic resin , Avoid the effect of low devolatilization temperature and easy gelation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

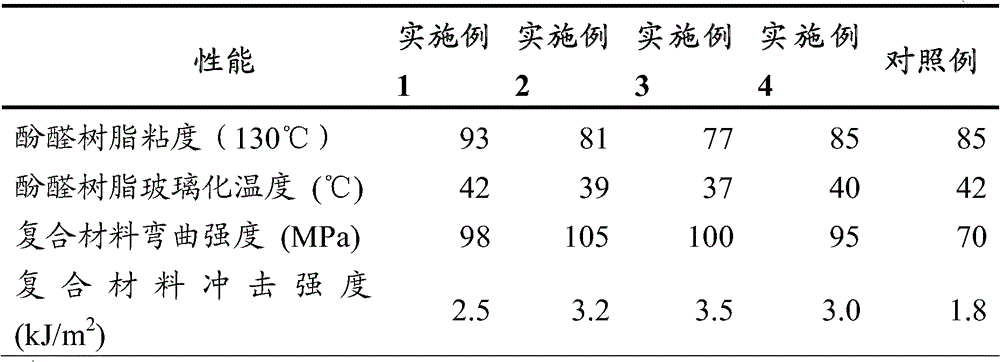

Embodiment 1

[0024] Put 400g of phenol, 40g of nylon-1212 and 3g of oxalic acid into a 2L reactor, start stirring, and heat to 100°C. At this time, nylon-1212 will gradually dissolve in the phenol to form a homogeneous solution. Then, slowly add metered aqueous formaldehyde solution (37% mass fraction) dropwise with a constant pressure dropping funnel (the molar ratio of phenol to formaldehyde is 1:0.8), keep the temperature in the reactor at 94-100°C, and the dropping time is 20 -30 minutes. The reaction was continued at reflux temperature for about half an hour, and the system would reach the cloudy point of phase transition, thereby turning into a milky white turbid liquid. Finally, the reaction was continued at reflux temperature for 2 hours. Then, connect the vacuum exhaust pipe, under constant stirring, decompression devolatilization for two hours, the vacuum degree is 0-0.1MPa, then, the temperature of the system will slowly rise to 150 ℃, and continue the decompression devolatiliza...

Embodiment 2

[0026] Add 400g of phenol, 80g of nylon-1212 and 3g of oxalic acid into a 2L reactor, stir continuously, and heat to 100°C. At this time, nylon-1212 will gradually dissolve in the phenol to form a homogeneous solution. Then, slowly add metered aqueous formaldehyde solution (37% by mass) dropwise with a constant pressure dropping funnel (the molar ratio of phenol to formaldehyde is 1:0.8), the reaction temperature is 94-100°C, and the dropwise addition takes 20-30 minutes . As the reaction proceeds, the system will pass through the phase transition cloud point and become a milky white turbid liquid, and finally, continue to react at reflux temperature for 2 hours. Then, connect the vacuum pumping tube, stir constantly, decompress and devolatilize for 2 hours, the vacuum degree is 0-0.1MPa, the temperature will slowly rise to 150°C, continue to decompress and devolatilize for 1 hour, and finally discharge the material while it is hot, Nylon-1212 modified phenolic resin was obta...

Embodiment 3

[0028] Put 400g of phenol, 40g of nylon-11 and 3g of oxalic acid into a 2L reactor, stir continuously, and heat to 100°C. At this time, nylon-11 will gradually dissolve in the phenol to form a homogeneous solution. Then, slowly add metered aqueous formaldehyde solution (37% by mass) dropwise with a constant pressure dropping funnel (the molar ratio of phenol to formaldehyde is 1:0.8), keep the temperature at 94-100°C, and add dropwise for 20-30 minutes . Then, the reaction was continued for half an hour at the reflux temperature, and the system would pass through the phase change cloud point and become a milky white cloudy liquid for 2 hours. Then, connect the vacuum pumping tube, and keep stirring, devolatilize under reduced pressure for two hours, the initial vacuum degree is 0-0.1MPa, the temperature will slowly rise to 150°C, and continue to devolatilize for 1 hour, finally, release while hot Material, get nylon-11 modified phenolic resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com