Large-scale low-order brown coal upgrading tower

A lignite and large-scale technology, applied in the field of dry distillation, can solve the problems of difficult sealing of the system, large system investment, excessive ash content of semi-coke, etc., and achieve the effect of simple equipment, easy manufacture, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

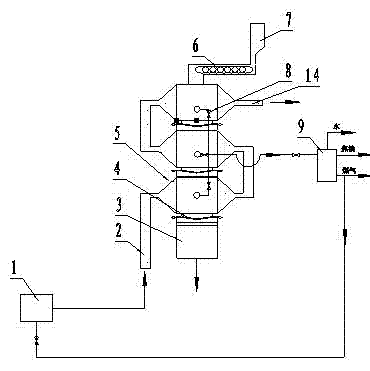

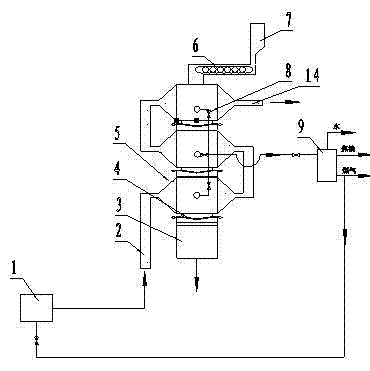

[0015] see figure 1 , the present invention includes a tower body, a combustion chamber 1, a coal bunker 7, and a screw feeder 6. The coal bunker and the screw feeder are located at the top of the tower body, and a semi-coke outlet 3 is provided at the bottom of the tower body. The tower body is composed of several vertically stacked unit towers 5, and the number of unit towers can be flexibly assembled according to coal types and production requirements, usually 3-5 unit towers are set. The high-temperature flue gas sent from the combustion chamber 1 passes through the S-shaped high-temperature flue 2, and enters the heating pipes in each unit tower sequentially from bottom to top. Each unit tower is equipped with a gas outlet pipe, and a gas valve 8 is located on the outlet pipe. The upper unit tower is provided with a flue exhaust duct 14 .

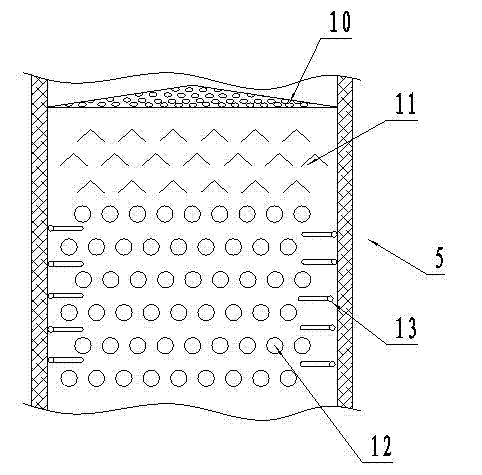

[0016] see figure 2 , Each unit tower 5 is provided with evenly distributed plates 10, wear-resistant tiles 11, and heating pipes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com