UV-lithographic micro-patterned organic thin film transistor semiconductor material and application

A technology of organic semiconductors and organic thin films, applied in the fields of semiconductor devices, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., can solve the problems of photocrosslinkable semiconductor materials that have not been reported in any form.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

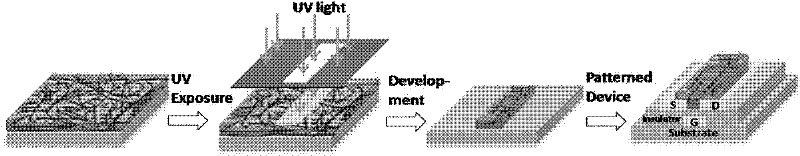

Method used

Image

Examples

Embodiment 1

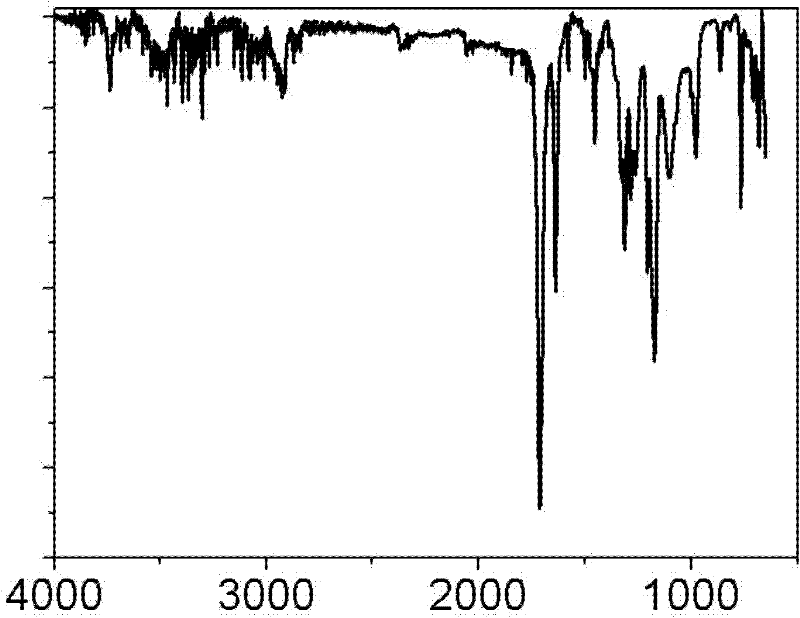

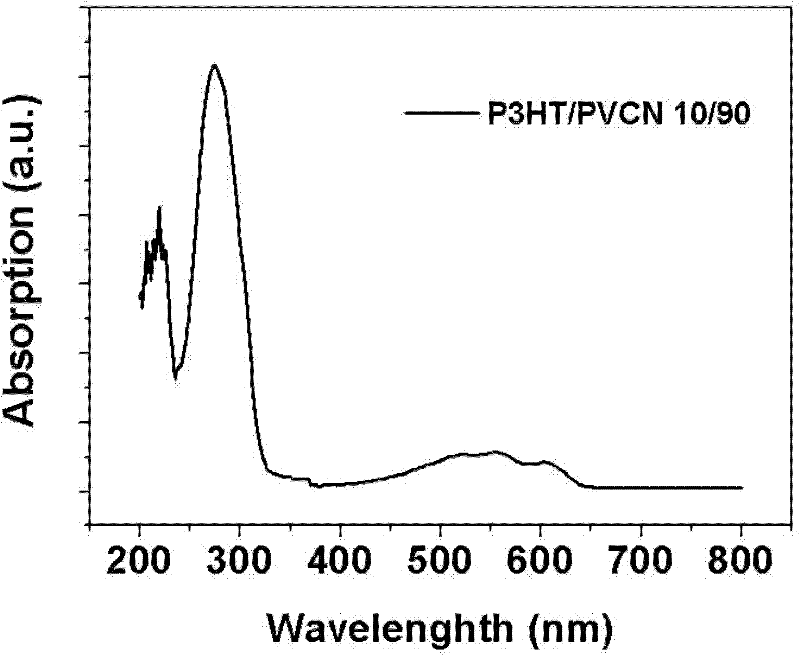

[0032] Dissolve P3HT and polyvinyl cinnamate (PVCN) in trichlorethylene at different ratios (P3HT / PVCN: 50% / 50%-1% / 99%) to make a solution with a concentration of 2%, and then To this solution was added dropwise 1-50 vol% dioxane; a thin film was prepared on a silicon wafer with a rotation speed of 2000 rpm.

Embodiment 2

[0034] Dissolve P3HT and polyvinyl cinnamate (PVCN) in different ratios (P3HT / PVCN: 50% / 50%-1% / 99%) in dichloromethane at 40°C to make a concentration of 2%. solution, and then the temperature of the solution was lowered to room temperature at a rate of 5°C / 10min, and a thin film was prepared on a silicon wafer with a rotation speed of 2000rpm.

Embodiment 3

[0036] Replace polyvinyl alcohol cinnamate with polyvinyl alcohol p-methyl cinnamate, and then prepare a film according to the steps in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com