Cutting tool and method for treating surface thereof

A technology of cutting tools and sand blasting treatment, which is applied in the field of cutting tools and its surface treatment, can solve the problems of not being smooth and flat, poor surface resistance to chipping, low wear resistance, etc., to improve surface conditions and wear resistance The effect of sex and toughness and excellent durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

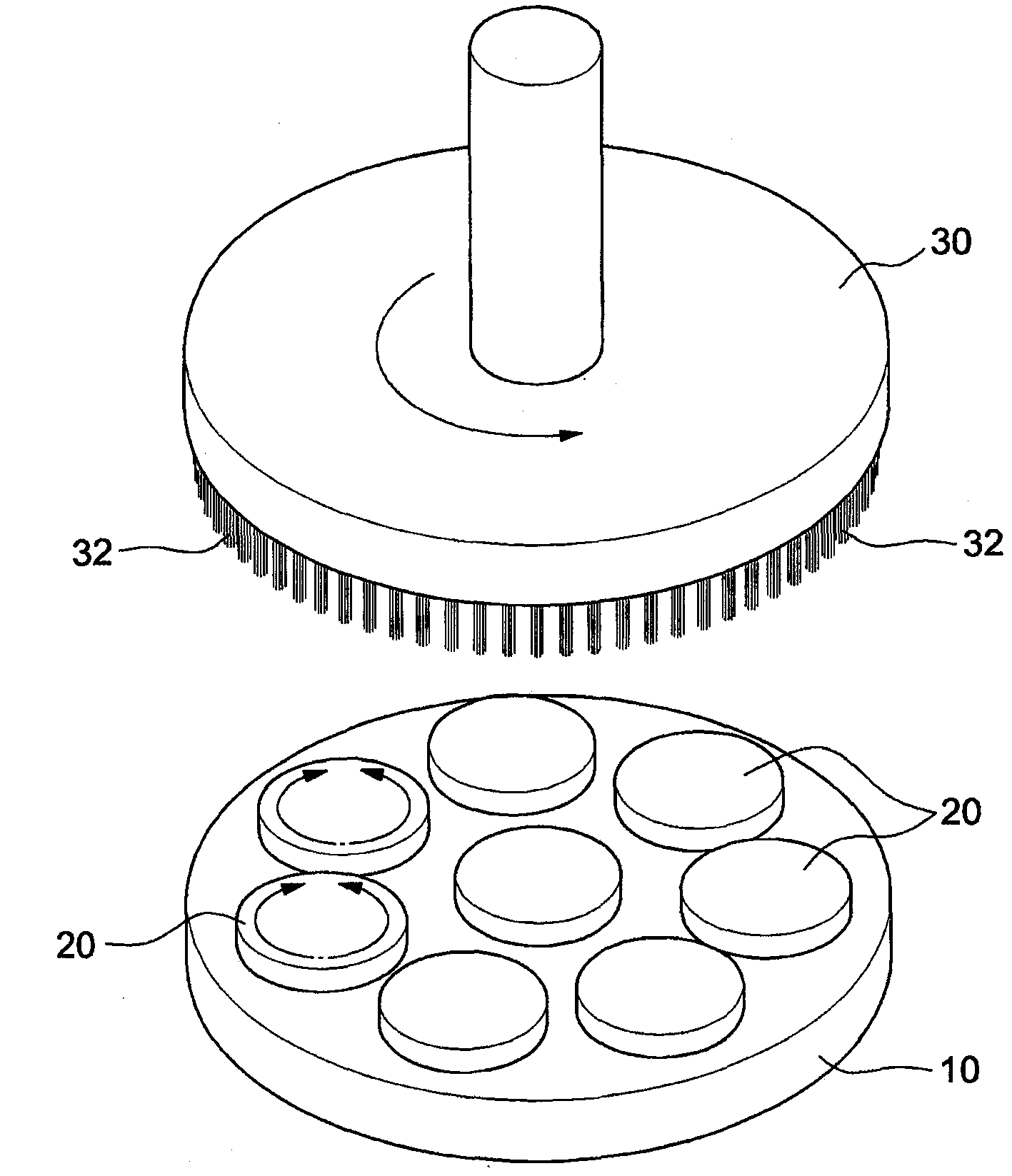

Method used

Image

Examples

Embodiment approach 1-3

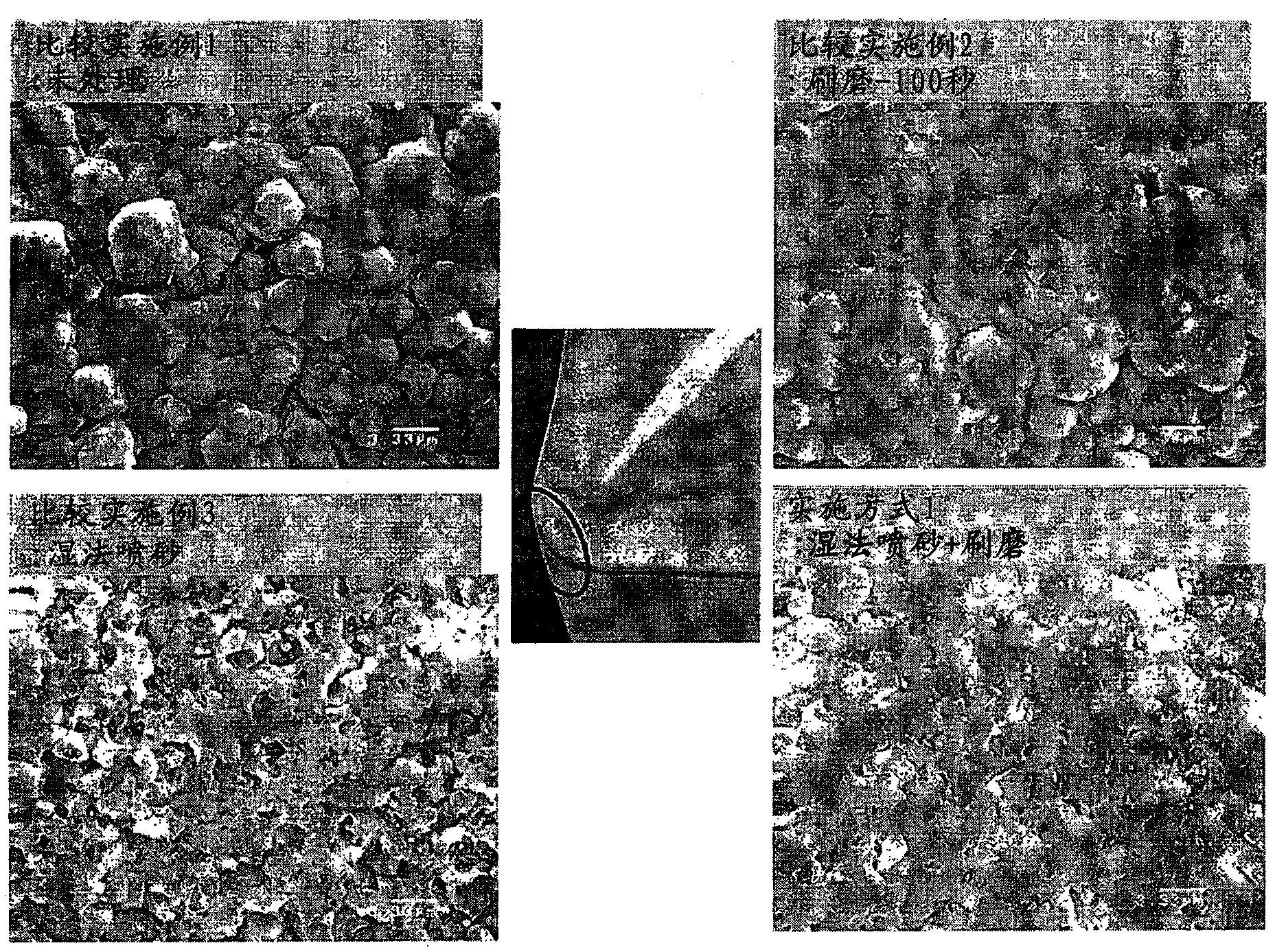

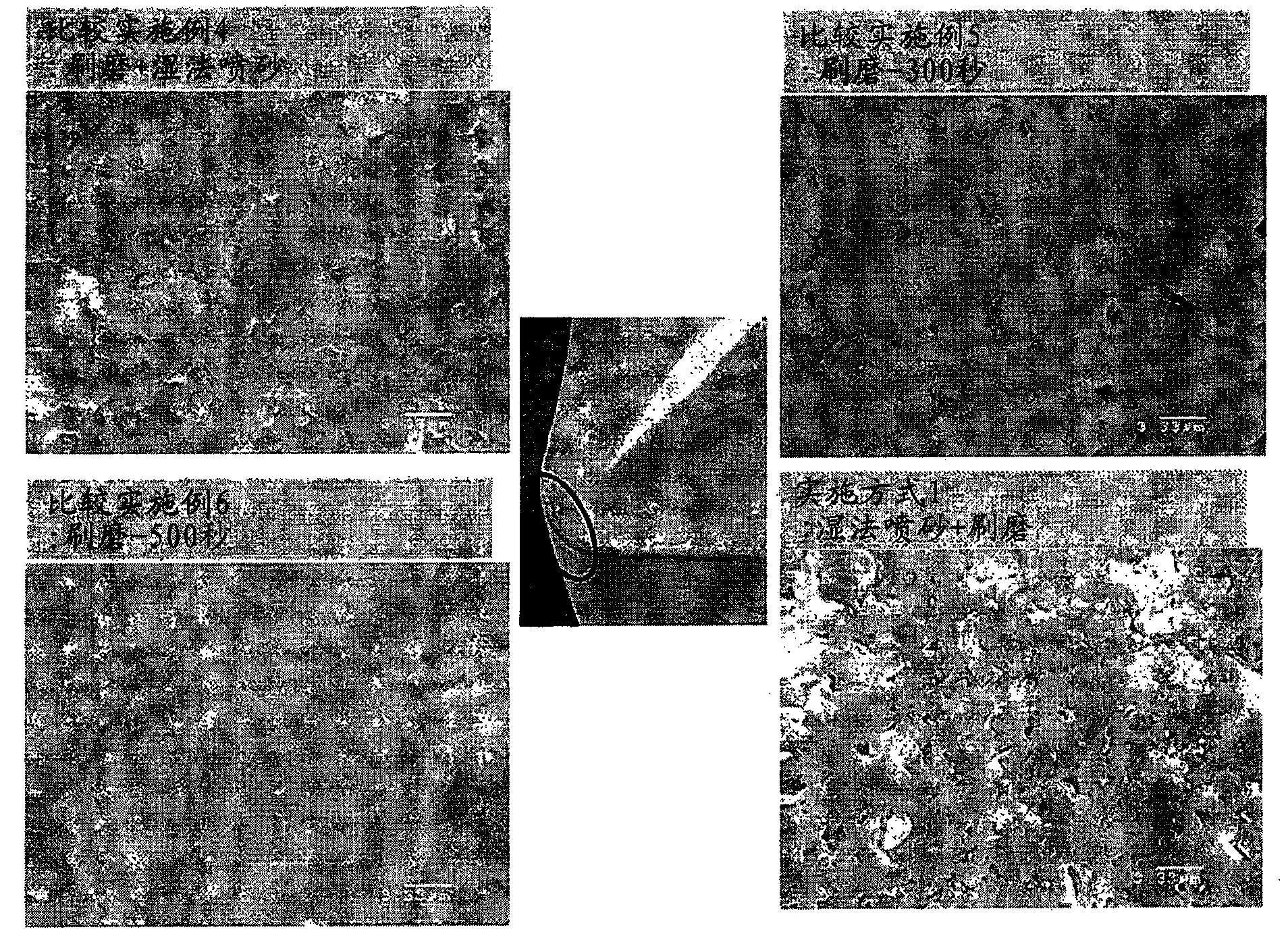

[0045] Commonly used Al coated on cemented carbide base material with 15μm 2 o 3 Layered CNMG 12 cutting inserts were used as target samples, on which the grit blasting and brushing treatments were successively performed.

[0046] Wet blasting

[0047] The surface of the cutting insert (CNMG 12 type) was subjected to wet blasting under the conditions shown in Table 1 by using a wet blasting apparatus. Alumina particles of the Treibather product known as Alodur were used as abrasives, which were 170 mesh (90 μm) alumina particles and 230 mesh (63 μm) alumina particles at a ratio of 1: 1 in the form of a mixture by weight ratio. The density of the abrasive was 1.01 kg / l (amount of alumina contained in 1 1 of a mixture of alumina and water).

[0048] Table 1 wet blasting treatment conditions

[0049] parameter

unit

Embodiment 1

Embodiment 2

Embodiment 3

spray gun pressure

-bar

1.4

1.8

2.5

gun movement speed

mm / min...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap