Ultrahigh-purity germanium single crystal preparation process and special equipment

A technology of preparation process and special equipment, which is applied in the field of ultra-high-purity germanium single crystal preparation process and special equipment, can solve the problems such as unreachable, achieve the effect of guaranteeing purity, high cleanliness, and reducing the possibility of mixed impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

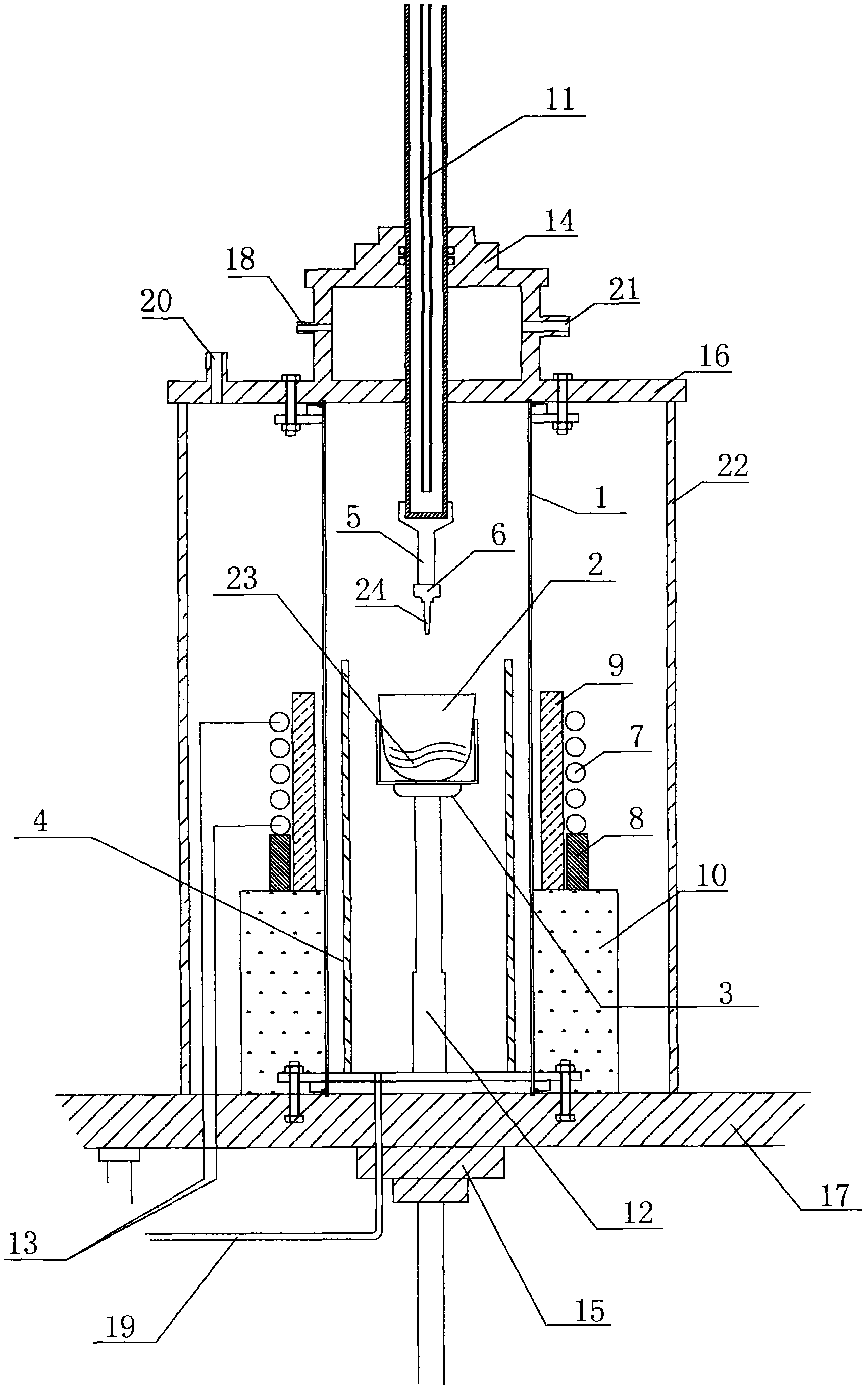

[0029] The purpose of the present invention is to provide an ultra-high-purity germanium single crystal preparation process and special equipment that can produce less than 5000 dislocations per square centimeter and a purity of 12-13N. The prepared germanium single crystal can be used to make detectors and is widely used. It is used in various military and civilian fields such as military defense, customs border inspection, food sanitation inspection, environmental monitoring, etc.

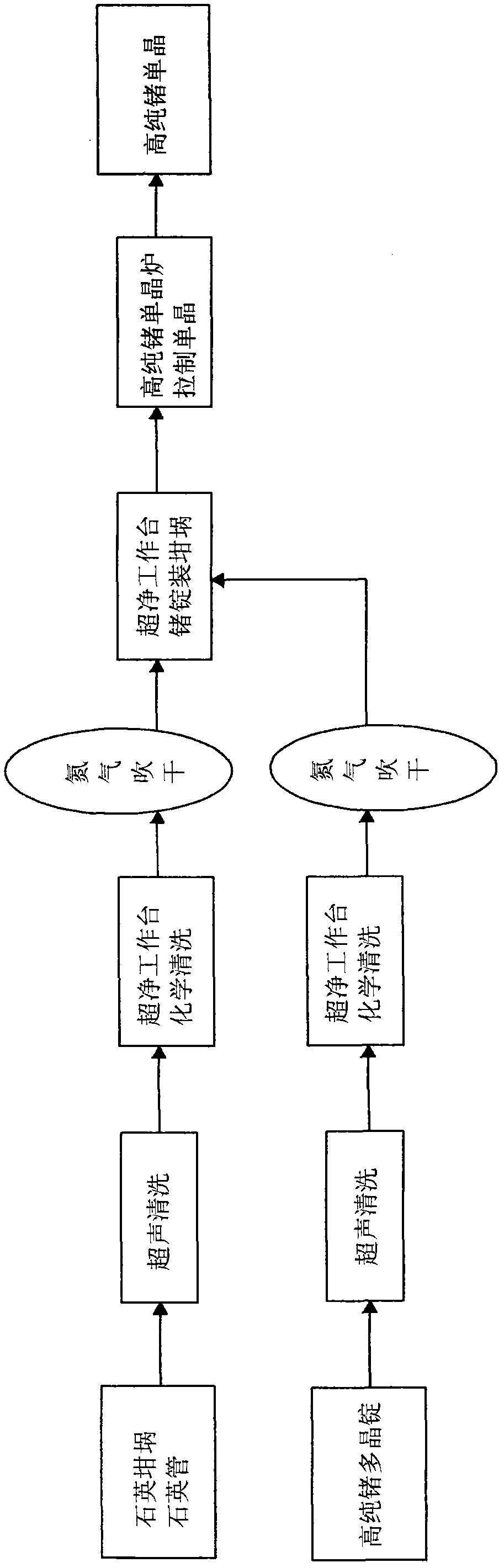

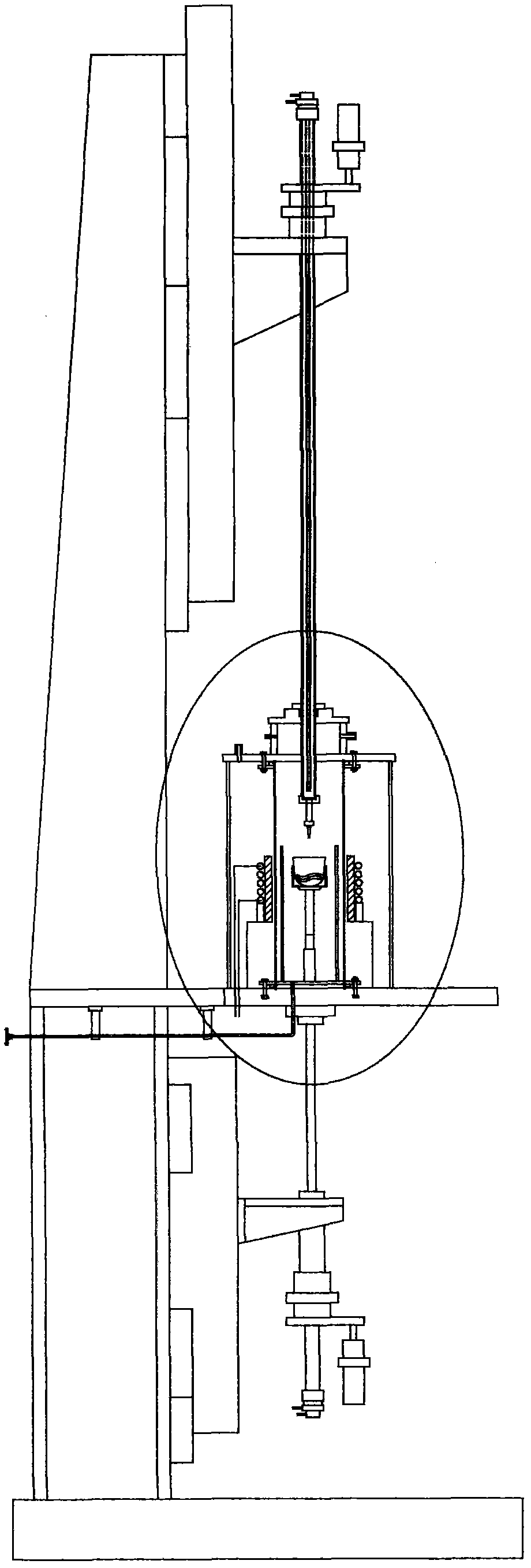

[0030] figure 1 Shown is the flow chart of the preparation process of the high-purity germanium single crystal of the present invention. The ultra-high-purity germanium single crystal preparation process of the present invention includes two parts: cleaning of polycrystalline ingots and crystal pulling equipment, and single crystal pulling by a single crystal furnace.

[0031] The cleaning of the polycrystalline ingot sequentially includes the ultra-clean water cleaning of the ultrasonic cleaner...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com