Alkali-developable photosensitive resin composition, and partition suitable for display element and display element formed by employing same

A technology of photosensitive resin and alkali developability, which is applied in the direction of optical components, electrical components, nonlinear optics, etc. It can solve the problems of no mention of compatibility, no touch of anti-ink properties, reduced ink-resistance, etc., and achieve surface appearance And the effect of good pattern shape, excellent surface ink repellency, and excellent compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

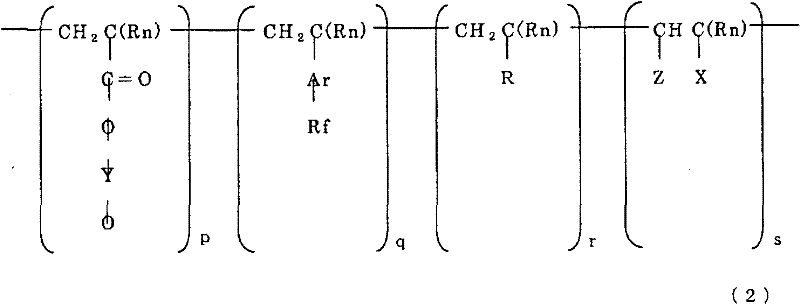

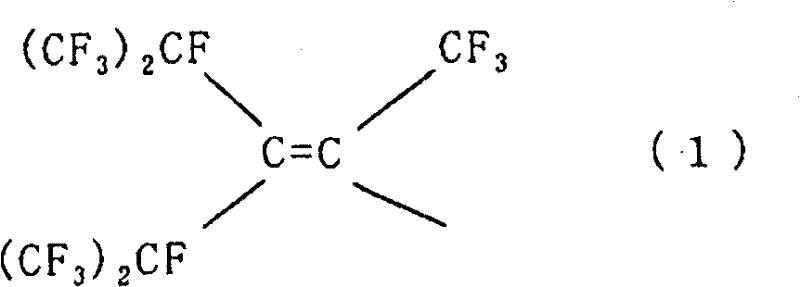

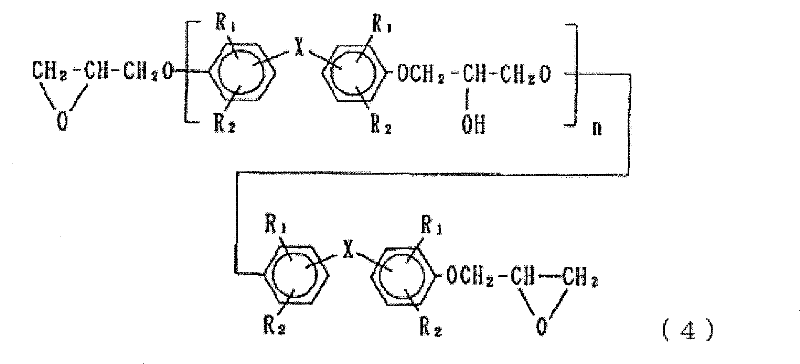

Method used

Image

Examples

Embodiment 1~14 and comparative example 1~2

[0129] First, components (B) to (F) other than the fluororesin (A) component and YX-4000H (manufactured by Showa Shiel; tetramethyldiphenyl epoxy resin) were listed in Table 2 and Table 3. Proportions (parts by weight) were mixed, and propylene glycol monomethyl ether acetate was added to make the solid content concentration 20% by mass. Continue to add (A) component solution with the mass parts described in Table 2 and Table 3. Next, use a 2μm polypropylene membrane filter at 0.2kg / cm 2 Filtration was performed under pressure to prepare an alkali-developing photosensitive resin composition. In Table 2 and Table 3, the compounding ratio with respect to the total solid content is shown by mass % in () of (B) component. In addition, the compounding ratio of (E) component is shown in another column as (pigment / total solid content) mass % with respect to the total solid content. In addition, the meanings of the abbreviations in Table 2 and Table 3 are as follows.

[0130] (B)-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com