Piezoelectric element and preparation method thereof

A piezoelectric element and piezoelectric technology, applied in the field of piezoelectric elements and their preparation, can solve the problems of easy brittleness, poor reliability of piezoelectric elements, and poor elasticity of piezoelectric ceramic nanowires, and achieve excellent elasticity. , the effect of excellent elasticity and piezoelectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

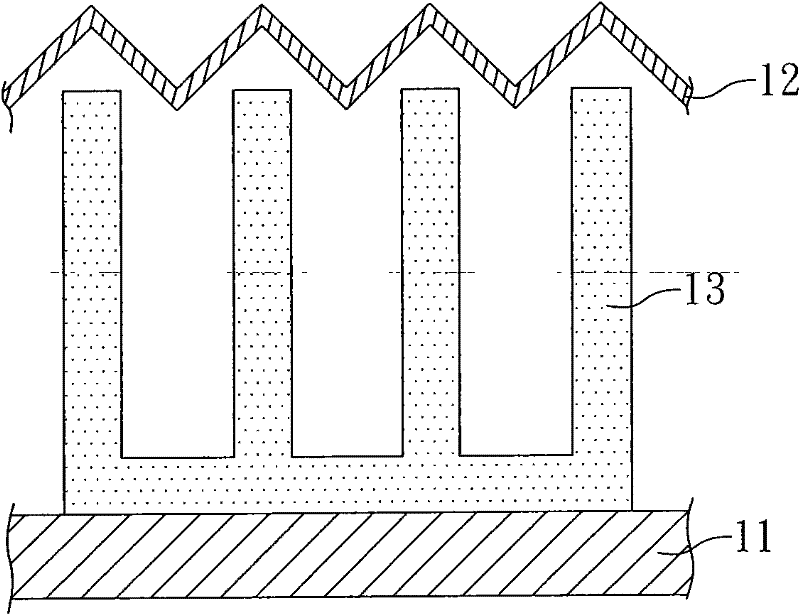

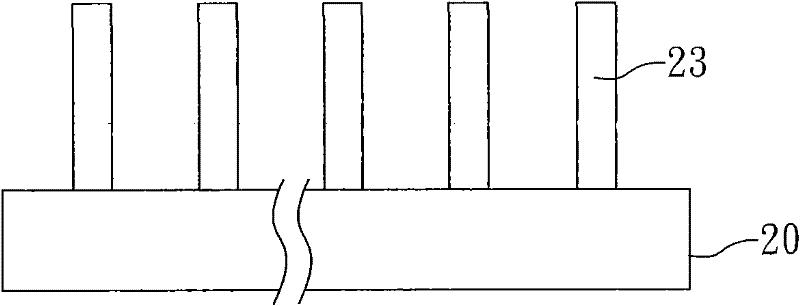

[0057] see Figure 2A-Figure 2H , which is a schematic diagram of the fabrication process of the piezoelectric element of this embodiment. First, (a) provide a substrate 20 (such as Figure 2A shown); then (b) forming a plurality of carbon nanotubes 23 on the surface of the substrate 20 (such as Figure 2B shown). In this embodiment, the substrate 20 used is a silicon-based substrate.

[0058] And then, (c) form a zinc oxide layer 24 (that is, a piezoelectric ceramic layer) on the surface of a plurality of carbon nanotubes 23 (such as Figure 2C shown). Here, the zinc oxide layer 24 is formed on the surfaces of the plurality of carbon nanotubes 23 by atomic layer deposition. And, (c0) repeat the step 800 times (not shown) of forming the zinc oxide layer 24 on the surface of the plurality of carbon nanotubes 23 in the step (c), so that the total thickness of the zinc oxide layer 24 reaches a predetermined value (about ).

[0059] Then, (d) use a thermal vaporization met...

Embodiment 2

[0068] see Figure 4A-Figure 4F , which is the flow chart of the preparation of the piezoelectric element of this embodiment. First, (a) provide a substrate 20 (such as Figure 4A shown); then (b) forming a plurality of carbon nanotubes 23 on the surface of the substrate 20 (such as Figure 4B shown). In this embodiment, the substrate 20 used is a silicon-based substrate.

[0069] And then, (c) form a zinc oxide layer 24 on the surface of a plurality of carbon nanotubes 23 (such as Figure 4C shown). Here, the zinc oxide layer 24 is formed on the surface of the plurality of carbon nanotubes 23 by atomic layer deposition. And, (c0) repeat the step 800 times (not shown) of forming the zinc oxide layer 24 on the surface of the plurality of carbon nanotubes 23 in the step (c), so that the total thickness of the zinc oxide layer 24 reaches a predetermined value (about ).

[0070] Then, (d) use a vacuum infiltration method to fill a supporting material 25 between a plurality...

Embodiment 3

[0074] A piezoelectric block 3 is prepared in the same manner as in Example 2 (steps (a) to (e) of Example 3), such as Figure 4A to Figure 4F shown. Next, if Figure 5 As shown, proceed to step (f1): respectively form the first conductive layer 21 and the second conductive layer 22 on the two side surfaces 33, 34 of the piezoelectric block 3, and make the first conductive layer 21 and the second conductive layer 22 respectively It is electrically coupled with the zinc oxide layer 24 in the piezoelectric block 3 .

[0075] like Figure 5 As shown, in the piezoelectric element 2 of this embodiment, the first conductive layer 21 and the second conductive layer 22 are connected in series with the piezoelectric block 3 (that is, the first conductive layer 21 and the second conductive layer 22 The surface of the piezoelectric block 3 is roughly parallel to the arrangement direction of the carbon nanotubes 23 in the piezoelectric block 3). And when the series length L2 exceeds 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com